Preface. What follows are two articles. The first has excerpts from Calstart’s study of the effects cold weather had on lithium and Sodium Nickel Chloride e-truck batteries.

The second article is from Consumer Reports, which says that half of driving range is lost, because below freezing, lithium ion batteries don’t perform well. Perhaps this is why nearly half of PHEV/BEV vehicles are sold in balmy California (chart at very bottom after references), while the half of the states with the coldest temperatures – freezing or below, didn’t buy 50% of electric cars as you’d expect, but just 23% of them, and half of that total is from the five states that offer state subsidies.

It’s possible cold weather will be yet another factor preventing the adoption of electric trucks and cars in all states. And since you need trucks to keep civilization running, which depend on diesel fuel, what’s the big deal about EV cars? That just frees up gasoline, which diesel engines can not burn.

Li J et al (2021) Multiphase, Multiscale Chemomechanics at Extreme Low Temperatures: Battery Electrodes for Operation in a Wide Temperature Range. Advanced Energy Materials. Lithium ion batteries are a bit famous for their poor cold-weather performance, and that has consequences for some of their most important applications – everything from starting an electric car in a Wisconsin winter to flying a drone on Mars. An overlooked aspect is that storing lithium-ion batteries at below freezing temperatures can crack some parts of the battery and separate them from surrounding materials, reducing their electric storage capacity, up to 5% or more of their capacity after 100 charges than batteries stored at warmer temperatures.

Alice Friedemann www.energyskeptic.com Women in ecology author of 2021 Life After Fossil Fuels: A Reality Check on Alternative Energy best price here; 2015 When Trucks Stop Running: Energy and the Future of Transportation”, Barriers to Making Algal Biofuels, & “Crunch! Whole Grain Artisan Chips and Crackers”. Podcasts: Crazy Town, Collapse Chronicles, Derrick Jensen, Practical Prepping, KunstlerCast 253, KunstlerCast278, Peak Prosperity

***

CALSTART (2013) E-truck performance in cold weather.

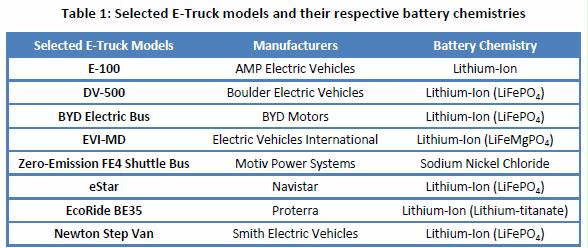

Several different battery chemistries are used in transportation applications: Lead-Acid, Nickel Metal Hydride, Lithium-Ion, Sodium Nickel. Table 1 shows the different e-trucks and their battery chemistry studied in this document.

SUMMARY OF DRIVING RANGE EXPECTATIONS

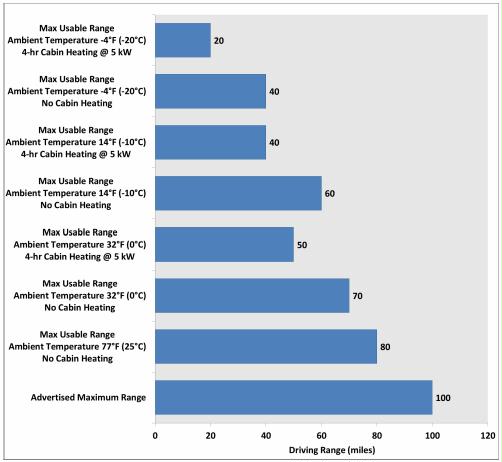

Figure 8 shows the combined impact of cold temperatures and cabin heating on an E-Truck equipped with a cabin heater with a power draw of 5 kW and an advertised range of 100 miles.

From the 80-mile maximum usable range, we can then see the impact of cold temperatures and cabin heating on driving range:

- With ambient temperature throughout the day at 32°F (0°C), the E-Truck maximum usable range would decrease to 70 miles with no cabin heating and 50 miles with 4 hours of cabin heating at 5 kW power draw.

- With ambient temperature throughout the day at 14°F (-10°C), the E-Truck maximum usable range would decrease to 60 miles with no cabin heating and 40 miles with four hours of cabin heating at 5 kW power draw.

- With ambient temperature throughout the day at -4°F (-20°C), the E-Truck maximum usable range would decrease to 40 miles with no cabin heating and 20 miles with four hours of cabin heating at 5 kW power draw.

Lithium-Ion

Both high and low temperatures impact Lithium-Ion battery performance. At high temperatures, side reactions happen faster leading to faster battery degradation.

At cold temperatures, battery performance (power and energy) is lower due to poor ion transport. This leads to poor vehicle acceleration, limited capability to recover braking energy and lower driving range than experienced in warmer temperatures.

Each battery chemistry has its own unique performance degradation curve. Lithium-Ion batteries generally see their performance decrease gradually when ambient temperature drops from 80°F (27°C) to 32°F (0°C). However, performance falls off sharply when ambient temperature drops below 32°F (0°C).

- At 32°F (0°C), relative capacity is about 90% of the capacity at the testing temperature of 77°F (25°C).

- At 14°F (-10°C), relative capacity is about 80% of the capacity at the testing temperature of 77°F (25°C).

- At -4°F (-20°C), relative capacity is about 60% of the capacity at the testing temperature of 77°F (25°C).

In addition, Lithium-Ion battery charging is much more challenging at cold temperatures as battery degradation is accelerated and the probability of a catastrophic failure is increased. As a result, Lithium-Ion batteries are generally inhibited from charging below 32°F (0°C).

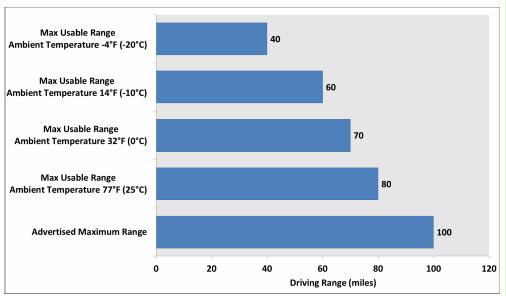

Figure 5: Impact of Lithium-Ion battery operating temperature on the driving range of an E-Truck with no cabin heating

When fleets deploy E-Trucks, they generally include a “buffer” to the advertised maximum range to limit “range anxiety”. This buffer is in addition to the OEM programmed battery buffer needed to preserve battery life. While every fleet may chose a different buffer, we chose a reasonable 20% that decreases the 100-mile advertised maximum range to an 80-mile maximum usable range with ambient temperature at 77°F (25°C). From this 80-mile maximum usable range, we can then see the impact of cold temperatures on driving range:

- With ambient temperature throughout the day at 32°F (0°C), the E-Truck maximum usable range would decrease to 70 miles.

- With ambient temperature throughout the day at 14°F (-10°C), the E-Truck maximum usable range would decrease to 60 miles.

- With ambient temperature throughout the day at -4°F (-20°C), the E-Truck maximum usable range would decrease to 40 miles.

The 100-mile advertised maximum range to an 80-mile maximum usable range with ambient temperature at 77°F (25°C). From this 80-mile maximum usable range, we can then see the impact of cold temperatures on driving range:

- With ambient temperature throughout the day at 32°F (0°C), the E-Truck maximum usable range would decrease to 70 miles.

- With ambient temperature throughout the day at 14°F (-10°C), the E-Truck maximum usable range would decrease to 60 miles.

- With ambient temperature throughout the day at -4°F (-20°C), the E-Truck maximum usable range would decrease to 40 miles.

Lithium-Ion battery performance is affected by cold temperatures. The extent of the performance degradation will depend on various factors:

- Starting temperature (at which temperature are the batteries when the E- Truck starts its day),

- Drive cycle (do the batteries have time to cool down when the vehicle is stopped on a delivery),

- Outside temperature (what is the ambient temperature the batteries are exposed to).

We estimate that Lithium-Ion batteries used in current E-Trucks could lose 10 to 20% state of charge in typical Chicago winter weather (from 14°F to 32°F) and up to 40% in extreme cold weather (-4°F). For a 100-mile truck, this would represent a 10 to 20-mile reduction in driving range and up to a 40-mile reduction in extreme cold weather.

Sodium-Nickel batteries present the advantage of being able to operate at extreme temperatures from 40 to 149°F (-40 to +65°C) with no performance degradation. Since the electrolyte used in Sodium-Nickel batteries is solid and inactive at normal ambient temperatures, batteries are continuously kept at their internal working temperature of 518°F (270°C) in order to keep the electrolyte molten and the battery ready to use. Thus, Sodium-Nickel batteries provide consistent performance regardless of the outside temperature and charge normally at cold temperatures. In 2012, Motiv Power Systems was awarded a contract with a total value of $13.4 million from the City of Chicago to electrify up to 20 garbage trucks. In order to meet the range requirements provided by the City of Chicago (drive 60 miles all year-round), Motiv Power Systems uses Sodium-Nickel Chloride batteries. Figure 6 below shows the first US all- electric Class 8 refuse truck from Motiv Power Systems.

During initial testing in December 2013, no degradation of performance was observed. Between 50% and 60% of total battery capacity is used for driving regardless of the outside temperature, leaving enough battery capacity to run trash compaction and vehicle accessories.

Sodium-Nickel batteries present several drawbacks compared to Lithium-Ion batteries:

- Sodium-Nickel batteries have lower power density than Lithium-Ion batteries. Thus, they are not suited for every truck application.

- Sodium-Nickel batteries are not shipped at their operating temperature and thus need 24 hours to heat up to 280°C prior to being used.

- Sodium-Nickel batteries are better for high usage applications (such as refuse), as the batteries will cool down if not in use or not connected to a power source. While this would not damage the batteries, a 24-hour period would be needed to reheat them to their 280°C operating temperature.

- While connected to a power source, Sodium-Nickel batteries will draw power to keep batteries warm (less than 100 W).

- There is currently only one commercial-stage supplier of Sodium-Nickel batteries for E-Truck applications (FIAMM), which is a limiting factor for the further adoption of Sodium-Nickel batteries.

We can see that cabin heating represents a significant energy draw on E-Truck batteries: from 16 kWh for a 4 kW cabin heater operated for four hours in a day, to 48 kWh for a 6 kW cabin heater operated for eight hours in a day. Chassis dynamometer testing of a Smith Electric Newton Step Van at the Argonne National Laboratory (see Chapter 7 for reference) showed a 40% increase in energy consumption (and thus a 40% decrease in driving range) at cold temperatures of 20°F (-7°C) compared to ambient temperatures of 70°F (-21°C).

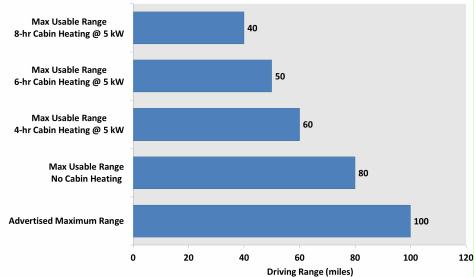

Figure 7: Impact of cabin heating on the driving range of an E-Truck

From the 80-mile maximum usable range, we can then see the impact of cabin heating on driving range:

- With 4 hours of cabin heating at 5 kW power draw, the E-Truck maximum usable range would decrease to 60 miles.

- With 6 hours of cabin heating at 5 kW power draw, the E-Truck maximum usable range would decrease to 50 miles.

- With 8 hours of cabin heating at 5 kW power draw, the E-Truck maximum usable range would decrease to 40 miles.

We can see that cabin heating represents a significant energy draw on E- Truck batteries: from 16 kWh for a 4 kW cabin heater operated for four hours in a day, to 48 kWh for a 6 kW cabin heater operated for eight hours in a day. Chassis dynamometer testing of a Smith Electric Newton Step Van at the Argonne National Laboratory showed a 40% increase in energy consumption (and thus a 40% decrease in driving range) at cold temperatures of 20°F (-7°C) compared to ambient temperatures of 70°F (-21°C). The

Figure 7 shows the impact of cabin heating on an E-Truck equipped with a cabin heater with a power draw of 5 kW and an advertised range of 100 miles. Although outdoor temperatures would be low enough to require cabin heating, in order to quantify the impact of cabin heating on driving range, we assumed in that case cold temperatures would not affect battery performance.

We estimate that cabin heating use could decrease state of charge (SOC) by 20% in typical delivery operation and up to 40% in operation where the driver requires longer periods of cabin heating.

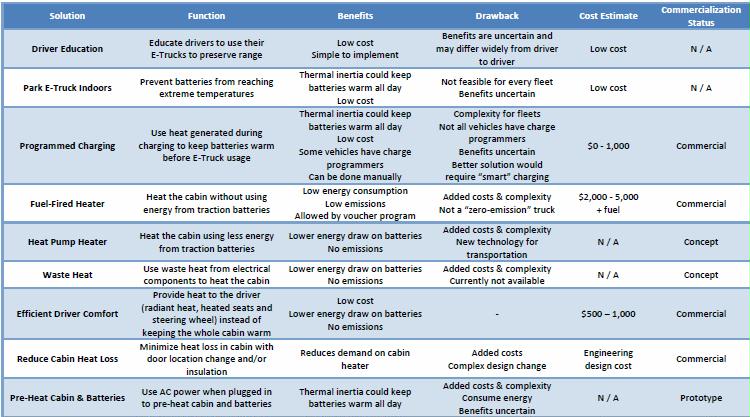

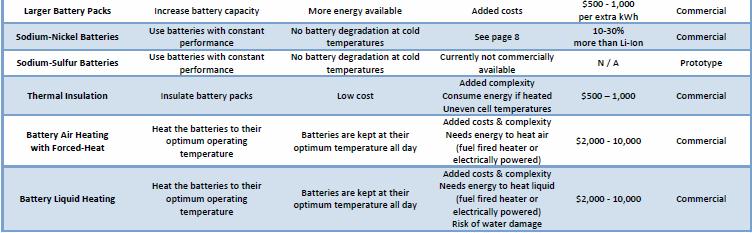

Lastly, we researched potential solutions that would help maintain E-Truck driving range in cold climate.

Table 3: List of potential solutions to help maintain E-Truck driving range in cold climate

Related articles

There are many other barriers to building a battery electric truck. They use many finite platinum group elements, precious elements, and rare earth elements. Plus there are dozens of challenges to improving batteries that must be overcome but mostly can’t be due to the laws of physics and thermodynamics. Nor are trucks going to be running on hydrogen: The dumbest & most impossible renewable

The electric grid will eventually fail without utility scale energy storage of at least a month of electricity to compensate for seasonal deficits (see When Trucks Stop Running Chapter 17 The Electric Blues). Natural gas is the main energy storage now, as well as coal, and the main and often only way to balance the sudden life and death of wind and solar power. Sure, hydropower can also be used in the 10 lucky states that have 80% of it, and the few places that can afford multi-million-dollar batteries (though only for an hour). Natural gas also provides peak power in extreme heat or cold. But natural gas is finite. The electric grid could crash from a weapon or solar flare electromagnetic pulse and be down for a year or more. Electric trucks are impossible. Without trucks, civilization fails. Manufacturing uses over half of all fossil fuels, and depends on the high heat only they can generate (see Chapter 9 of Life After Fossil Fuels).

CR. 2019. Winter temperature averages for every state. Current results

Consumer reports tested cars in cold weather, less than freezing, and found they lose about half their normal driving range. So cold state EV buyers have to spend more than warmer states for longer ranges or they may be left stranded in a cold snap. The colder it gets below freezing, the worse the battery performance, and especially pronounced below 0° F. It’s not just the cold draining the batteries, extra demands are put on them for heating and defoggers. Consumer reports recommends keeping the car in the garage plugged in until you leave (Olsen 2019).

“Batteries are like humans,” says Anna Stefanopoulou, director of the University of Michigan’s Energy Institute. They prefer the same sort of temperature range that people do. Anything below 40 or above 115 degrees Fahrenheit and they’re not going to deliver their peak performance. They like to be around 60 to 80 degrees. As the temperature drops, the electrolyte fluid inside the battery cells becomes more sluggish. “You don’t have as much power when you want to discharge,” says Stefanopoulou. “The situation is even more limited when you want to charge.”

there are workarounds. First, don’t let the battery get too low—make sure you always have a 20 percent charge or so. If you want to power up in subzero temperatures, the car may need that reserve to warm the battery enough to start the process. “Don’t think that being near an outlet to charge will get you out of trouble,” Stefanopoulou says. (Stewart 2019)

When it comes to putting electrons into the battery, freezing weather hurts in two regards. It limits regenerative braking, so the car recoups less power and drivers can’t rely on one-pedal driving. And charging, particularly fast charging, will be limited to protect the battery.

Californians bought 153,442 PHEV or BEV in 2018, nearly half of all electric/hybrids in the country.

But 21 other states bought 11,221 in total, just 3.4%, and the top 9 states bought 73% of them. Half of the states, the 26 with the coldest average winter temperatures of 32 or less, bought just 23% of the cars. But that total is skewed towards states that offer subsidies, half of these cars were bought in the 5 cold states with them: New York, Colorado, Massachusetts, and Connecticut (EVAdoption 2019, CR 2019, Gorzelany 2018).

REFERENCES

American Automobile Association (2014). Extreme Temperatures Affect Electric Vehicle Driving Range, AAA Says. http://newsroom.aaa.com/2014/03/extreme- temperatures-affect-electricvehicle-driving-range-aaa-says/

Duoba, M., E. Rask, M. Meyer, APRF & Co (2012). Advanced Powertrain Research Facility AVTA Nissan Leaf testing and analysis. Argonne National Laboratory, October 12th, 2012.

EVAdoption. 2019. EV Market share by state. EVAdoption

Gorzelany, J. 2018. Here’s which states are best for owning an electric car. Forbes.

Jehlik F et al (2014) Electric Heater Effects on two Medium Duty Electric Trucks, from Argonne & FedEx EV Evaluations. Handout for the National Governor’s Association Workshop on Advanced Vehicle Technologies and Infrastructure. Indianapolis, IN.

Olsen, P. 2019. Buying an electric car for a cold climate? Double down on the range. Consumer reports.

Pesaran A et al (2013) Addressing the Impact of Temperature Extremes on Large Format Li-Ion Batteries for Vehicle Applications. National Renewable Energy Laboratory, NREL/PR-5400-58145. 30th International Battery Seminar, Fort Lauderdale, FL http://www.nrel.gov/docs/fy13osti/58145.pdf

Stewart, J. Why electric cars struggle in the cold – and how to help them. Wired.

The Truth About Electric Vehicles (EVs) in Cold Weather. On-Demand Webinar. https://www.fleetcarma.com/Resources/the-truth-about-electric-vehicles-in- cold-weatherwebinar

State 2018 includes hybrids % of EV sales Avg winter temp F Temp rank Rebates

California 153,442 0.47 46.2 8 2500-4500

New York 15,752 0.05 23.3 38 2000

Florida 13,705 0.04 59.4 2

Washington 12,650 0.04 33 21

Texas 11,764 0.04 47.9 4

New Jersey 9,230 0.03 33 21

Massachusetts 8,990 0.03 27.4 34 2500

Illinois 7,357 0.02 28.3 32

Arizona 7,086 0.02 43.6 10

Colorado 7,051 0.02 25.8 35 5000

Virginia 6,375 0.02 36.8 15

Maryland 6,299 0.02 34.7 19

Pennsylvania 6,063 0.02 28.4 31

Georgia 6,004 0.02 47.8 5

0.14

Oregon 5,976 0.02 34 20

North Carolina 4,712 0.01 42.1 11

Ohio 4,456 0.01 29.5 28

Michigan 3,571 0.01 21.7 39

Connecticut 3,415 0.01 28.5 30 3000

Minnesota 2,853 0.01 12.4 48

Oklahoma 2,683 0.01 39 13

Nevada 2,325 0.01 32.2 25

Hawaii 2,296 0.01 67.4 1

Utah 2,295 0.01 28.2 33

Missouri 2,268 0.01 32.3 24

Indiana 2,036 0.01 29.4 29

Tennessee 1,994 0.01 39.1 13

Wisconsin 1,956 0.01 17.2

South Carolina 1,170 0.00 46.1 9

New Hampshire 1,123 0.00 21.1 43

Kansas 943 0.00 31.9 26

Iowa 917 0.00 21.7 39

Alabama 866 0.00 46.5 7

Vermont 824 0.00 19.4 45

Maine 799 0.00 16.8 47

Kentucky 787 0.00 35.9 18

District of Columbia 761 0.00 34.7 19

New Mexico 705 0.00 36.1 16

Nebraska 628 0.00 25.7 36

Delaware 627 0.00 36.1 16 2200

Rhode Island 619 0.00 31.4 27

Louisiana 613 0.00 50.9 3 1500

Idaho 497 0.00 25.4 37

Arkansas 435 0.00 41.5 12

Montana 274 0.00 21.2 41

Mississippi 231 0.00 46.7 6

West Virginia 218 0.00 32.8 23

Alaska 155 0.00 -16.3 50

South Dakota 135 0.00 19.5 44

North Dakota 95 0.00 12.2 49

Wyoming 92 0.00 21.2 41

Total 328,118

3 Responses to Electric truck & car range less in cold weather