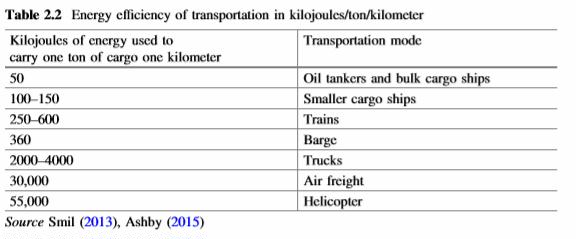

Preface. As oil declines and the energy crisis worsens, airplanes ought to be the first to go since they are 600 times less energy efficient than large cargo ships (30,000 / 50), 50 to 120 times less efficient than trains, and 7.5 to 15 times less efficient than trucks.

Though airplanes will continue to fly, because they use kerosene, which is a fraction of every crude barrel of oil, and much of it can’t be converted to diesel (trucks, rail, ships) or gasoline (cars). Though ships can burn just about anything, and since they carry 90% of all global trade, perhaps kerosene can keep them going a bit longer.

Kerosene is the fraction of choice for airplanes for a number of reasons. First, it has a much higher flash point than gas, commonly around 464°F. Second, kerosene has a freezing point of -57 F, which is not uncommon at the high altitudes planes fly at. In fact, it’s usually – 67 F — but the kerosene doesn’t freeze because the plane is flying through this cold air mass at hundreds of miles per hour. The speed of air over the wings creates friction, heating the surfaces (Page 2020).

United States air carriers burn through 17 billion gallons of jet fuel annually. The amount of fuel an airliner needs depends on many factors, including aircraft type, weight and direction of travel. Here are some price estimates for 2019 (Stewart 2019):

- Los Angeles International to Tokyo Narita: This trans-Pacific hop uses an estimated 9,500 gallons of jet fuel at an estimated price of $19,190.

- New York JFK to Los Angeles International: This popular transcon flight uses an estimated 5,325 gallons of jet fuel at an estimated price tag of $10,757. The return to New York uses slightly less fuel at 5,075 gallons with an estimated price of $10,252.

- Chicago O’Hare to Miami International: Heading southbound, this flight operates using an estimated 2,350 gallons, with an estimated cost of $4,747. On the northbound return, the cost estimate soars to $7,201, using an estimated 3,565 gallons.

- Denver International to San Francisco International Airport: This particular route can see significant variances in fuel quantity and pricing because of the variety of aircraft operating between the two cities. On average, aircraft fill up with an estimated 3,500 gallons of jet fuel, costing an estimated $7,070. However, price can vary from $4,040 on the low end to $14,140 on the high end.

It’s also been found that if airplanes flew in birdlike formations, the way geese fly in a V, up to 10% of their energy could be saved as well as emissions lowered (Khadilkar 2021).

Alice Friedemann www.energyskeptic.com author of “Life After Fossil Fuels: A Reality Check on Alternative Energy“, 2021, Springer; “When Trucks Stop Running: Energy and the Future of Transportation”, 2015, Springer; Barriers to Making Algal Biofuels, and “Crunch! Whole Grain Artisan Chips and Crackers”. Podcasts: Collapse Chronicles, Derrick Jensen, Practical Prepping, KunstlerCast 253, KunstlerCast278, Peak Prosperity , XX2 report

* * *

Nygren, E., et al. 2009. Aviation fuel and future oil production scenarios. Energy Policy 37/10: 4003-4010

Jet fuel is extracted from the middle distillates fraction and competes with the production of diesel. Aviation fuel is almost exclusively extracted from the kerosene fraction of crude oil.

Today global oil production is roughly 81.5 million barrels per day (Mb/d), which is equivalent to an annual output of 3905.9 Mt.

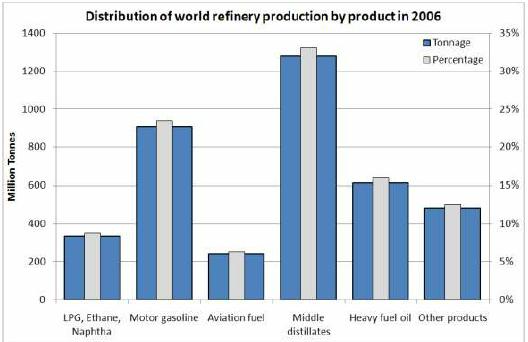

Aviation fuels include both jet fuel for turbine engines and aviation gasoline for piston engines. The dominant fuel is jet fuel originating from crude oil as it is used in all large aircraft. Jet fuel is almost exclusively extracted from the kerosene fraction of crude oil, which distills between the gasoline fraction and the diesel fraction. The IEA estimated the world’s total refinery production in 2006 was 3861 million tonnes (Mt). The aviation fuel part was 6.3%, implying an annual aviation fuel production of 243 Mt (corresponding to about 5 Mb/d), including both jet fuel and aviation gasoline.

Figure 3 shows how the world’s refinery production is divided into different fractions.

Figure 3: Distribution of world refinery production in 2006. The total production was 3861 Mt. Source: International Energy Agency, 2008b. Key World Energy Statistics 2008 and previous editions, see also: http://www.iea.org/textbase/nppdf/free/2008/key_stats_2008.pdf

If the refinery would like to increase jet fuel production, diesel production must decrease. During the year the proportion between diesel and jet fuel production changes and the fuel most profitable at that moment is produced.

Swedish Environmental class-1, ultra-low sulphur, diesel is a prioritized product, which has the consequence that no jet fuel at all is manufactured. The kerosene fraction is blended directly into the diesel fraction to provide the correct viscosity properties. Having fewer products is a way to increase the efficiency of the refinery.

The conclusion to be drawn is that aviation fuel production is not a fixed percentage of refinery output. In 2006, aviation fuel was 6.3% of world refinery production. The kerosene fraction is an average of 8-10% of the crude oil, but all kerosene does not become jet fuel or diesel. Kerosene can also be used to decrease the viscosity of the heavy fractions of crude oil and is used as lamp oil in certain parts of the world.

The environmental parameters that define the operating envelope for aviation fuels such as pressure, temperature and humidity vary dramatically both geographically and with altitude. Consequently, aviation fuel specifications have developed primarily on the basis of simulated performance tests rather than defined compositional requirements. Given the dependence on a single source of fuel on an aircraft and the flight safety implications, aviation fuels are subject to stringent testing and quality assurance procedures. The fuel is tested in a number of certified ways to be sure of obtaining the right properties following a specification of the international standards from, for example, IATA guidance material, ASTM specifications and UK defense standards (Air BP, 2000). Tests are done several times before the fuel is finally used in an airplane.

Today, the increasing addition of biofuels to diesel is a problem for the aviation industry. One of the more common biodiesels is FAME (Fatty Acid Methyl Esther). FAME is not a hydrocarbon and no non-hydrocarbons are allowed in jet fuel, except for approved additives as defined in the various international specifications such as DEF STAN 91-91 and ASTM D 1655. Consequently, biofuels-contaminated jet fuel cannot be utilized due to jet fuel standards. The problem with FAME is that it has the ability to be absorbed by metal surfaces. Diesel and jet fuel are often transported in a joint transport system making it possible for FAME stuck in tanks, pipelines and pumps to desorb to the jet fuel. The limit for contamination of jet fuel with FAME is 5 ppm. FAME can be picked up in any point of the supply chain, making 5 ppm a difficult limit and therefore the introduction of biofuels to the diesel fraction has had a negative impact upon jet fuel supply security.

References

Ashby, M.F., 2015. Materials and sustainable development table A.14.

Khadilkar D (2021) Tight Flight: A birdlike formation would save fuel for planes. Scientific American.

Page, C. 2020. How do pilots know how much fuel to take on a flight? thepointsguy.com

Smil, Vaclav. 2010. Prime Movers of Globalization. The History and Impact of Diesel Engines and Gas Turbines pp 160, 204

Stewart, M. 2019. How much does it cost to fuel up an airliner? thepointsguy.com

4 Responses to Airplanes are energy gluttons. Finite oil should be used for ships, locomotives, & trucks