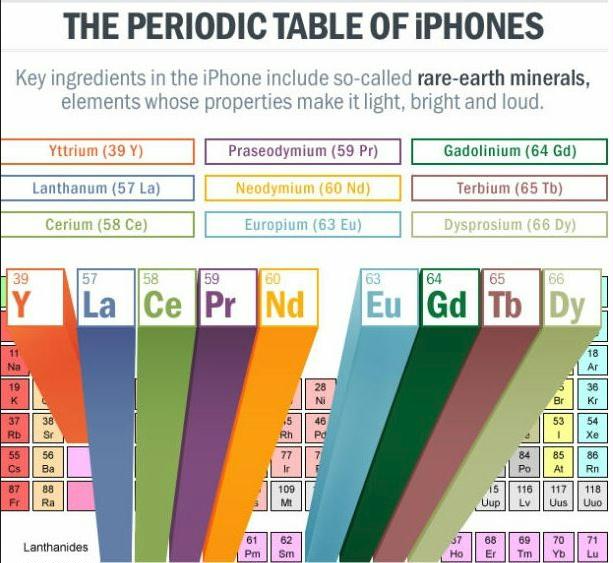

There are 17 rare earth elements in the periodic table. About nine of those elements go into every iPhone sold… and if China were suddenly to disappear from a map tomorrow, Apple would lose about 90% of those elements. Source: Brownlee 2013.

There are 17 rare earth elements in the periodic table. About nine of those elements go into every iPhone sold… and if China were suddenly to disappear from a map tomorrow, Apple would lose about 90% of those elements. Source: Brownlee 2013.

Preface. This long post describes the rare metals and minerals phones, laptops, cars, microchips, and other essential high-tech products civilization depends on. Without them, there can’t be a transition to wind turbines, solar panels, nuclear energy, and so on.

Metals and minerals aren’t just physically limited, they can be economically limited by a financial collapse, which dries up credit and the ability to borrow for new projects to mine and crush ores. Economic collapse drives companies and even nations out of business, disrupting supply chains.

Supply chains can also be disrupted by energy shortages & natural disasters.

The more complex, the more minerals, metals, and other materials, machines, chemicals, a product depends on, the greater the odds of disruption.

Minerals and metals can also be politically limited. China controls over 90% of some critical elements, for example, just three mines in China produce all of the world’s cesium.

And of course, they’re energetically limited. Once oil begins to decline, so too will mining and all other manufacturing steps, which all depend on fossil energy.

The next war over resources is likely to be done via cyber-attacks that take down an opponent’s electric grid, which would affect nearly all of the other essential infrastructure such as agriculture; defense; energy; healthcare, banking, finance; drinking water and water treatment systems; commercial facilities; dams; emergency services; nuclear reactors, information technology; communications; postal and shipping; transportation and systems; government facilities; and critical manufacturing (NIPP).

Cars require over 76 elements, with self-charging hybrid and plug-in hybrid vehicles having twice the supply chain raw material cost risks of conventional models (Bhuwalka et al 2021).

Alice Friedemann www.energyskeptic.com Women in ecology author of 2021 Life After Fossil Fuels: A Reality Check on Alternative Energy best price here; 2015 When Trucks Stop Running: Energy and the Future of Transportation”, Barriers to Making Algal Biofuels, & “Crunch! Whole Grain Artisan Chips and Crackers”. Podcasts: Crazy Town, Collapse Chronicles, Derrick Jensen, Practical Prepping, KunstlerCast 253, KunstlerCast278, Peak Prosperity

***

Rare Earth, Critical, & Platinum-group elements are used in many products:

- Magnets (Neodymium, Praseodymium, Terbium, Dysprosium, Samarium): Motors, disc drives, MRI, power generation, microphones and speakers, magnetic refrigeration

- Metallurgical alloys (Lanthanum, Cerium, Praseodymium, Neodymium, Yttrium): NimH batteries, fuel cells, steel, lighter flints, super alloys, aluminum/magnesium

- Phosphors (Europium, Yttrium, Terbium, Neodymium, Erbium, Gadolinium, Cerium, Praseodymium): display phosphors CRT, LPD, LCD; fluorescent lighting, medical imaging, lasers, fiber optics

- Glass and Polishing (Cerium, Lanthanum, Praseodymium, Neodymium, Gadolinium, Erbium, Holmium, Baryte): polishing compounds, decolorizers, UV resistant glass, X-ray imaging

- Catalysts (Lanthanum, Cerium, Praseodymium, Neodymium, ruthenium, rhodium, palladium, osmium, iridium, platinum): petroleum refining, catalytic converter, diesel additives, chemical processing, industrial pollution scrubbing

- Other applications:

- Aerospace: Beryllium

- Aluminum production (fluorspar), alloys (Magnesium, Scandium)

- Catalytic converters (Cerium)

- Cathode-ray tubes (Gadolinium, Terbium, Yttrium)

- Ceramics (Fluorspar)

- Computer chips (Indium)

- Defense (Neodymium, Praseodymium, Dysprosium, Terbium, Europium, Yttrium, Lanthanum, Lutetium, Scandium, Samarium)

- Drilling oil and gas (Baryte)

- Electric vehicles (Niobium) electric motors (Samarium)

- Electronics and electricity (Tungsten)

- Fertilizers

- Fire retardants (Antimony)

- Fiber optics (Germanium, Erbium)

- Fuel cells (SOFC use lanthaneum, cerium, prasedymium)

- Healthcare (Baryte, Erbium)

- Hybrid engines (Dysprosium)

- Integrated circuits (silicon metal)

- Lasers (Europium, Holmium, Ytterbium)

- LCD screens (Indium)

- Lenses (Lanthanum)

- Light-emitting diodes (LEDs) (Gallium)

- Lighting (Lanthanum, Samarium, Europium, Scandium)

- Luminescent compounds (Promethium)

- Mettalurgy and alloys (Baryte, Cerium)

- Nuclear power (Europium, Gadolinium, Cerium, Yttrium, Sm, Erbium, Beryllium, Niobiumm /sanaruyn)

- Oil refinery (Cerium)

- Optics (fluorspar)

- Phones, computers, hybrid vehicles, magnets (Cobalt)

- Photovoltaic cells (Germanium, silicon metal)

- Pigments

- Satellites (Niobium)

- Semi-conductors (gallium, Holmium)

- Steel production (coking coal, fluorspar, vanadium, Ytterbium)

- Superconductors (high-temperature) Bismuth, Thulium, Yttrium

- Superconductive compounds (Lanthanum)

- Telecommunications and electronics (Beryllium)

- Thermoelectric auto generators (Bismuth)

- Water Treatment

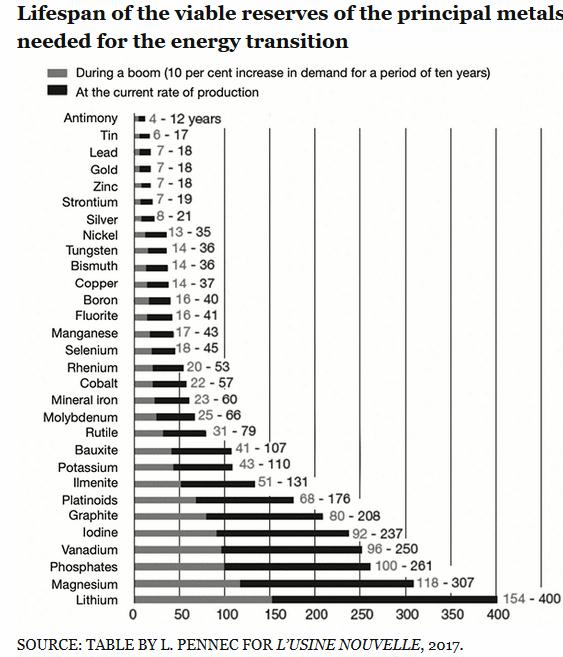

As you can see below, we are running of time to make an energy transition, and this is an optimistic estimate, since conventional oil peaked in 2018, the tremendous amount of energy needed to mine, smelt, fabricate into parts, transport to assembly factories, and deliver will shorten all of these time spans tremendously.

iPhones (Stone 2019)

200 million of iPhones are sold a year, each of them with 75 of the 118 elements in the periodic table, many of them rare, many of them sourced only from China. The minerals mentioned in this article were tungsten, tantalum, copper, tin, gold, silver, palladium, aluminum, cobalt, neodymium, gallium, all of which produce toxic byproducts during their mining and the refining of metals.

And less than one percent of these metals are recycled, due to the how difficult it is to collect enough electronic devices to make recycling worthwhile and getting the extremely minute quantities of metals out of them.

Each element was extracted from ores using hands, shovels and hammers, heavy machinery, and explosives, then smelted and refined into metals before being molded, cut, screwed, glued, and soldered into products that are stuffed into packages and shipped worldwide for sale. Every step in this production process requires fossil fuel energy.

Recycling is very expensive, and iPhones would need to cost $5,000 to recover the extreme costs recycling would entail. And recycling also generates a lot of waste as acids and other chemicals are used to try to separate the various metals from each other. Recycling also takes energy, and today it’s basically impossible to extract all the metals that went into a phone.

Apple’s parts are soldered and glued into place before being fastened together with proprietary screws which makes basic repairs like swapping out a broken screen or replacing a dead battery a headache. Which makes it difficult for anyone lacking a half dozen robotic arms to tear apart an iPhone to recycle the components. This is why most e-waste recyclers still primarily mainly recycle CRT TVs and other bulky, pre-smartphone-era devices. They don’t have the precision equipment to take apart a phone or tablet which were made difficult to tear apart, and they can potentially explode during the process.

For Apple, this may be a feature rather than a bug: Documents obtained by Motherboard in 2017 revealed that the company requires its recycling partners to shred iPhones and MacBooks so that their components cannot be reused, further reducing the value recyclers can get out.

Related: 2014 The chemical elements of a smartphone. This article lists dozens of elements required, both common and rare

Microchips: 60 minerals & metals

These are nearly as essential as fossil fuels to maintaining civilization, yet depend on 60 minerals & metals, chemicals, high-tech machines, etc., making them more vulnerable than any other product to supply chain and cascading failures.

While just 12 minerals were used to fabricate microchips initially, now over 60 different kinds of minerals are required (NMA 2017):

-

- The U.S. is 100% dependent on imports for 19 different minerals and over 50% for another 43 minerals. These trends are unsustainable in a highly competitive world economy in which the demand for minerals continues to grow and supply stability is a growing concern.

- Many of these minerals are both rare and past peak production

- Many of them come from only one country (single-source failure)

- China is the sole source for many of these minerals, and other countries such as failed nations like the Democratic Republic of Congo are not a reliable source.

Laptops need 44 raw materials from 27 Countries (Ruffle 2010)

Cesium is entirely produced in China. Some of its uses include (Kennedy 2020):

- strategic organic chemistry, including in x-ray radiation for cancer treatments.

- catalyst promoters, glass amplifiers and photoelectric cell components, crystals in scintillation counters, and getters in vacuum tubes.

- the oil and gas industry uses cesium formate brines in drilling fluids to prevent blow-outs in high-temperature, over-pressurized wells.

- the “cesium standard” is how accurate commercially available atomic clocks measure time, and it’s vital for the data transmission infrastructure of mobile networks, GPS and the internet.

- serious defense including in infrared detectors, optics, night vision goggles and much, much more.

References

Bhuwalka K et al (2021) Characterizing the Changes in Material Use due to Vehicle Electrification. Environmental Science & Technology 55: 10097

Kennedy, C. 2020. The Metal Trump Wants More Than Gold. oilprice.com

Pitron G (2020) The Rare Metals War: The Dark Side of Clean Energy and Digital Technologies. Scribe US.

Stone M (2019) Behind the Hype of Apple’s Plan to End Mining. Gizmodo.com

3 Responses to High-Tech can’t last: limited essential elements with limited lifespans