source: bitsandpieces1.blogspot.com

source: bitsandpieces1.blogspot.com

Preface. Before the age of fossil fuels, getting food, water, and shelter was simple. Nine out of ten people were self-sufficient farmers.

But now there are global 24/7 just-in-time supply chains that depend on trucks and other modes of transportation between us and what we need to survive.

Trucks carry 70% of all freight (by weight) an average of 206 miles. Five million medium and heavy-duty trucks travel 329 billion miles to deliver all these goods (ORNL).

Over 80% of communities in the United States depend completely on trucks for all their goods (ATA).

This is a shame! Trucks ruin roads, cause the most air pollution (75% of ghg), and waste the most energy by far. Rail is 4 times and ships up to 50 times more energy efficient than trucks (USDOE 2008, USDOT 2009, Notteboom, Tolliver).

Trucks can substitute for most other kinds of transportation, but the reverse isn’t true:

- Few factories, warehouses, and businesses have direct rail, barge, or ship connections.

- There are only 140,000 miles of freight rail tracks and 25,000 miles of commercially navigable waterways, but over 4 million miles of roads.

- Even if cargo could go by rail or ship, the cost to transfer it on and off again, or the risk of delay to just-in-time delivery, often make energy-inefficient trucks the preferred mode

- This means that even if some goods travel mainly by rail, ship, or barge, a truck is usually still needed to take the goods to and from the train yard and to the final destination.

Even a container arriving by ship and then rail will get on a truck three or more times:

- Sea port. Container is grabbed by a reach-stacker truck and loaded on a train

- Destination Train yard. Unloaded by a reach-stacker

- Loaded onto a truck for delivery to a regional distribution center or final store delivery

- Regional Distribution Center. Cargo consolidated for final delivery to local stores, and often transloaded to two smaller trucks if delivery in in a dense urban area.

Reach-stacker truck getting a container to load onto a truck or train

Reach-stacker truck getting a container to load onto a truck or train

Most businesses are very dependent on trucks:

- Trucks are a key part of the 24/7 just-in-time delivery system. Large grocery stores receive 10-15 truck shipments a day, assembly lines depend on regular deliveries of a wide range of parts from many suppliers within narrow time slots. Manufacturers have little packaging material on hand because it’s bulky and low value.

- Tax incentives and efficiency have driven businesses to keep as little inventory as possible and instead rely on frequent deliveries by trucks

Trucks fulfill our basic needs

Food. Trucks carry 83% of all food.

Never in human history have so many people lived so far from where their food is grown. In the past this would have caused famine, but gasoline and diesel trains, ships, and trucks solved this unprecedented problem.

- Two-thirds of food (by value) is grown in the inland states, but two-thirds of people live in coastal states (Atlantic, pacific, or gulf).

- By food calories, 92% of corn, 90% of soybeans, 80% of wheat, and 71% of cattle are produced in inland states.

Of all the various kinds of supply chains, from farm to table, food is the most truck-dependent.

Water. Trucks deliver water purification chemicals to water treatment plants every week or two.

Energy. Trucks deliver fuel to service stations every 2.4 days on average. Trucks also deliver fuel for trains, ships, and airplanes.

Health: Trucks keep pharmacies and hospitals stocked

Shelter: Trucks haul 92% of wood products and deliver materials to construction sites. Cement must arrive within 1-2 hours.

Electricity. 39% of electricity is generated by coal, which is delivered by train (71%) and truck (14%).

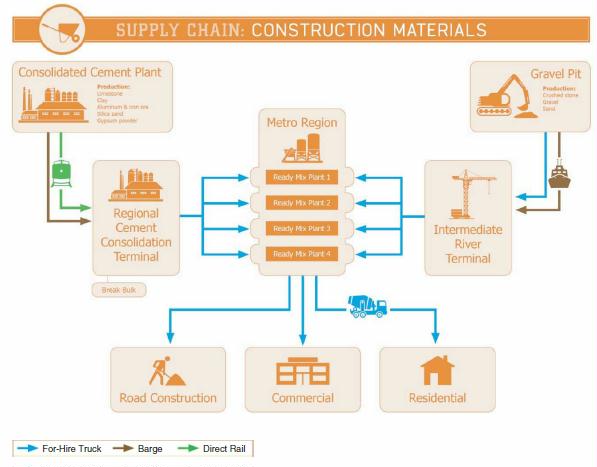

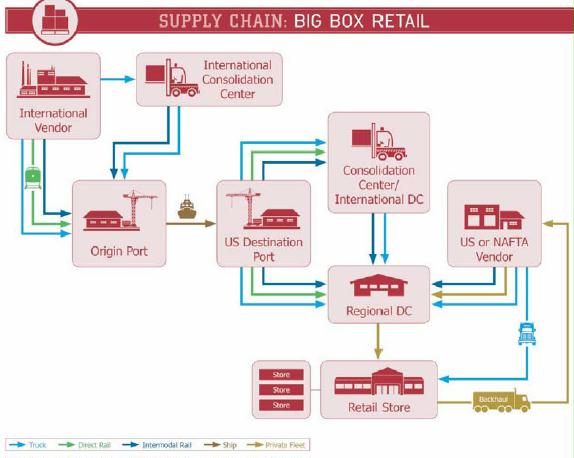

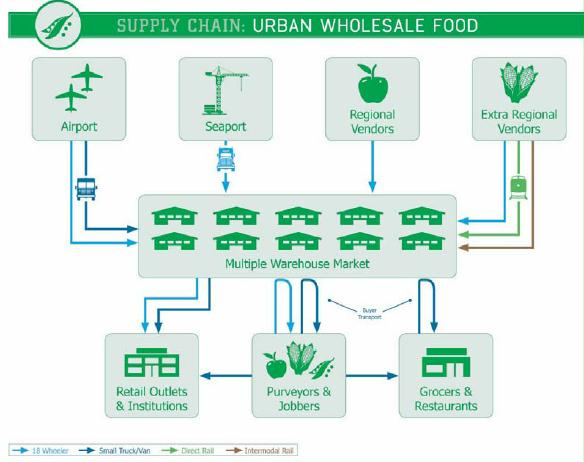

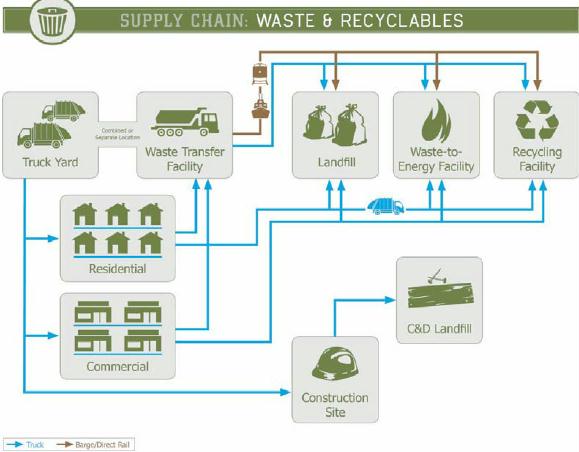

The National Academy of Sciences (NAS) looked at 12 urban supply chains. I’ve broken out a few of them by each leg of the journey goods move to show how important trucks are.

- T This leg depends completely on trucks

- t Trucks and other transport modes used

- – Trucks played no role

Alice Friedemann www.energyskeptic.com Author of Life After Fossil Fuels: A Reality Check on Alternative Energy; When Trucks Stop Running: Energy and the Future of Transportation”, Barriers to Making Algal Biofuels, & “Crunch! Whole Grain Artisan Chips and Crackers”. Women in ecology Podcasts: WGBH, Jore, Planet: Critical, Crazy Town, Collapse Chronicles, Derrick Jensen, Practical Prepping, Kunstler 253 &278, Peak Prosperity, Index of best energyskeptic posts

Urban Wholesale Food Supply Chain Exhibit A-3

T Multiple Warehouse Market. 18 Wheeler TRUCKS deliver food from airports, seaports, and regional vendors.

t Multiple Warehouse Market. 18 Wheeler TRUCKS and rail deliver food from extra regional vendors

T Retail outlets & Institutions, Purveyors & Jobbers, Grocers & Restaurants. All of these businesses receive food from the Multiple Warehouse Market by 18 Wheeler TRUCKS and smaller TRUCKS & VANS

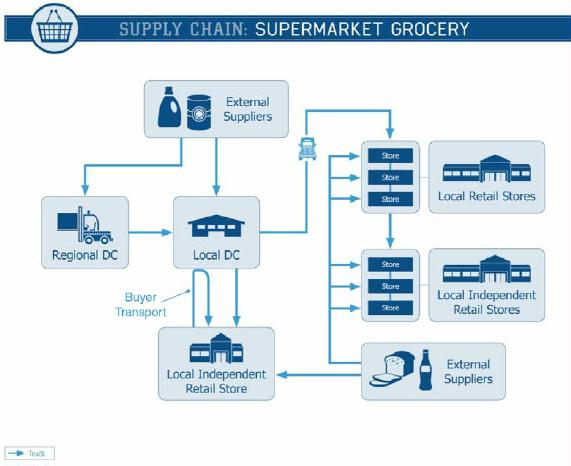

Supermarket Grocery Supply Chain Exhibit A-4

T Regional Distribution Center. TRUCKS deliver food from External Suppliers

T Local Distribution Center. TRUCKS deliver food from External Suppliers and Regional Distribution Center.

T Local Retail Stores. TRUCKS deliver food from External Suppliers and Local Distribution Center.

Farm to Table: The Dairy Supply Chain (USDA)

T Farm. TRUCKS deliver 65% of feed for cows

T Milk Processing Plant. Milk is transported in insulated tanker TRUCKS (avg of 5,800 gallons traveling 500 miles round-trip).

T Retail stores, schools. Packaged milk is distributed by refrigerated TRUCKS.

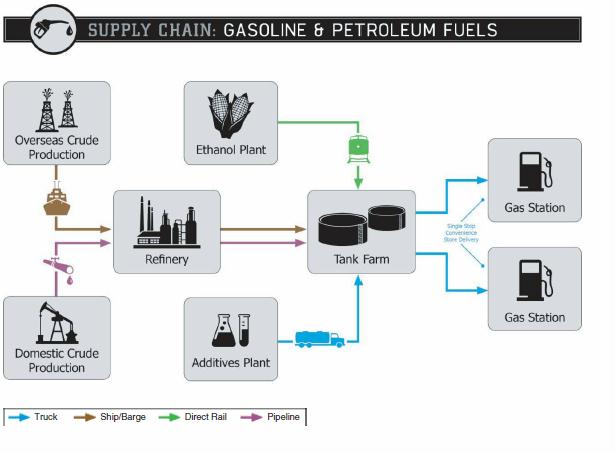

Gasoline and petroleum Supply Chain Exhibit 3-1

t Refinery: Crude petroleum from overseas arrives by ship or barge, Domestic crude by pipeline, and increasingly by train or TRUCK (i.e. North Dakota fracked oil).

t Tank Farm: Refined oil (i.e. diesel or gasoline) arrive by ship, barge, or pipeline, ethanol by train, and additives by TRUCK

T Gas Station: Diesel and gasoline arrive by TRUCK

Construction Materials (Cement) Supply Chain Exhibit 3-4

– Regional Cement Consolidation Terminal. Raw materials (limestone, clay, aluminum & iron ore, gypsum powder, silica sand) arrive by train or barge from the Consolidated Cement plant.

t Intermediate River Terminal. Raw materials (crushed stone, gravel, sand) arrive from a gravel pit by TRUCK or barge.

T Many Metro Region Ready Mix Plants. TRUCKS deliver raw materials from the Terminals above to many ready mix plants.

T Construction Sites (road, commercial, residential). Cement TRUCKS must reach these sites from local ready mix plants within one to two hours.

Next: When Trucks Stop Running, Civilization Stops Running.

References

NAS National Academy of Sciences. 2012. NCFRP Report 14: Guidebook for Understanding Urban Goods Movement.

Notteboom, T. et al. 2009. Fuel surcharge practices of container shipping lines: Is it about cost recovery or revenue making?. Proceedings of the 2009 International Association of Maritime Economists (IAME) Conference, June, Copenhagen, Denmark

ORNL transportation energy data book Edition 31. July 2012. Oak Ridge National Laboratory.

Tolliver, D, et al. October 2013. Comparing rail fuel efficiency with truck and waterway. Transportation Research Part D: Transport and environment. volume 24:69-75.

USDA. 2010. National Agricultural statistics service, agricultural statistics board.

USDOE. U.S. Department of Energy. 2008. Transportation Energy Data Book. 2008.

USDOT. U.S. Department of Transportation. 2009. National Transportation Statistics.

APPENDIX. WHAT IT IS LIKE TO BE A TRUCKER

If you want to know what it’s like to be a trucker, read “So You Want to be a Truck Driver (BigRig Training Book 1)”. It sure isn’t for everyone!

April 14, 2011. Drilling for a solution: finding ways to curtail the crushing effect of high gas prices on small business. U.S. House of Representatives. Small Business Committee Document Number 112–011

Dick Pingel. I live in Plover, Wisconsin, and have been a small business trucker for the past 28 years. I am a member of Owner-Operators Independent Drivers Association and currently run a one-truck operation hauling food around the country. As you are most likely aware, O-O-I-D-A, or OOIDA as it is known in the trucking industry, is a national trade association representing the interests of small business trucking professionals and professional truck drivers. The more than 152,000 members of OOIDA are small business men and women in all 50 states who collectively own and operate more than 200,000 individual heavy- duty trucks. The majority of the trucking community in this country is made up of small businesses as 93 percent of all carriers have less than 20 trucks in their fleet and 78 percent of carriers have just 6 or fewer trucks. In fact, a one-truck operation such as me represents nearly half of the total number of federally registered motor carriers.

Assuming that the trucking industry exclusively moves about 70 percent of our nation’s goods and that just about all freight is moved by truck at some point in the supply chain, it is not hard to see that the costs and burdens that encumber small business truckers have an impact on our nation’s businesses and consumers. The cost of fuel is very often the largest operating expense with which small business truckers must contend. For folks like me, fuel costs can easily be 50 percent or more of our annual operating expenses. To give you some perspective, the average OOIDA member runs their truck about 120,000 miles or more each year while getting somewhere in the ballpark of only 7 miles per gallon. Most of us will be operating trucks equipped with either twin 135-gallon tanks or twin 150-gallon tanks, so we can easily see a bill of over 1,000 dollars when we fill up.

In addition to the fuel going into the tanks of my tractor, I use a trailer with a diesel-powered refrigerating unit to haul dairy products for producers in Wisconsin. Until recently, I could count on it costing about $50 to fill up my tank for the reefer unit. However, in recent months the cost to fill this tank has increased to more than $100. The additional money I am now spending on fuel for my truck and trailer once went into investing in other areas of my business, but now it must cover basic operating expenses. Every time I pull into a truck stop I hear similar stories,

The national average for diesel is now around $4.12 a gallon, with prices in some states approaching $4.50 per gallon. To put this into perspective, each time the price of a gallon of diesel fuel increases by a nickel, a trucker’s annual cost increases by $1,000. Diesel prices today are more than a dollar higher than they were this time last year, resulting in an enormous extra burden on small business truckers whose average annual income is less than $40,000.

Small business truckers operate in a hyper competitive market, so managing their number one expense is imperative for their survival. In our marketplace, we often see costs increase without any corresponding rate increases. As such, the only way to survive is to become more efficient in how one operates their truck. Small business truckers always drive with an eye towards saving fuel no matter what the price because our business survival depends on it. As small business truckers like myself know, reducing fuel costs is not a science, it is an art and one that we pride ourselves on being masters of.

On biofuels and natural gas for trucks:

some of the states mandated B5. And the problem that we ran into at that time was during the winter because biofuel has a tendency to gel up faster. So it is great during the summer. And as far as natural gas, the problem with natural gas is the range on my truck right now in miles per gallon is over 1,000 miles. You cannot carry enough natural gas to go that far, and the range on most of the natural gas trucks that I have seen is right around 300 miles. So you are stopping consistently more times.

Pingback: Edito | Blog de Yoananda