Preface. In 2018 I thought it was time to reorganize this post, as it grew more and more bloated and disorganized with new information. Eventually it turned into my 2021 book Life After Fossil Fuels: A Reality Check on Alternative Energy, with even more information, but this post is free, and has some good sections that didn’t make it into my book.

I first published this online in 2007 as Peak Soil, Shorter versions appear in the following books: Jacqueline Langwith, ed. 2008. “Opposing Viewpoints: Renewable Energy, vol. 2.” Greenhaven Press; Sheila Newman, ed. 2008. “The Final Energy Crisis”. Pluto Press.

Alice Friedemann www.energyskeptic.com Women in ecology author of 2021 Life After Fossil Fuels: A Reality Check on Alternative Energy best price here; 2015 When Trucks Stop Running: Energy and the Future of Transportation”, Barriers to Making Algal Biofuels, & “Crunch! Whole Grain Artisan Chips and Crackers”. Podcasts: Crazy Town, Collapse Chronicles, Derrick Jensen, Practical Prepping, KunstlerCast 253, KunstlerCast278, Peak Prosperity

***

“The nation that destroys its soil destroys itself”, President Franklin D. Roosevelt

There’s growing public attention from the people about biomass potential for energy. There’s been a public discussion about many aspects and what the problems might be. But there’s one aspect of all of this that is conspicuous by its absence – a national discussion about the soil science – the effect growing row crops like corn and soy have on land and water. There are also important issues about whether there is enough biomass to scale up to replace oil, the net energy gain and the carbon balance. But the root of the matter is whether growing biomass for fuel can be made sustainable.

The lack of any kind of input on this by soil scientists about how we’re mining our soils is a voice that needs to be heard, because if you destroy the soil, you can’t grow biomass.

Part 1. Scale: There’s not enough biomass to fuel transportation

The amount of fossil fuels burned in 1997 is 400 times all the plant matter that grows in the world in a year, even including the microscopic plants in the ocean (Dukes 2003).

Since fossil fuels are finite, it certainly makes sense to turn to biomass to provide fuel to replace oil. After all, besides water, air, and dirt, plants are the most abundant and renewable resource that could possible scale up to replace fossil fuels.

But is there enough biomass? Don’t forget that oil, natural gas, and coal are used for many other purposes:

- Fossils are the source of over 500,000 products (fertilizer, plastics, petrochemical industry)

- Fossils provide baseload power for electricity generation and balance intermittent wind and solar power

- Fossils provide the high-temperature heat needed to make cement, steel, ceramics, and glass

- The heat for homes and businesses

In addition, a great deal of biomass is already spoken for – it is used for food, grazing, and fertilizer as so-called “crop waste” is increasingly tilled-in by farmers.

The Department of Energy lists ways biomass is already being used that will compete with its use as a fuel and for electricity generation (Ruth 2013 Table 3.3):

- Residential (including wood pellets for heat)

- Commercial (uses agriculture byproducts/crops, sludge waste, and other biomass solids, liquids and gases; black liquor and wood/wood waste solids including wood pellets for heat and liquids; and corn)

- Industrial, including:

- Agriculture, forestry, and mining (consumes agricultural byproducts/crops)

- Chemicals and allied products (consumes other biomass liquids, sludge waste, and wood/wood waste solids)

- Apparel (consumes wood and derived fuels)

- Petroleum refining (consumes wood and derived fuels)

- Rubber and miscellaneous plastic products (consumes wood and derived fuels)

- Transportation equipment (consumes wood and derived fuels)

- Stone, clay, glass, and concrete products (consumes wood and derived fuels)

- Furniture and fixtures (consumes wood and derived fuels)

Few studies look at how biomass would optimally be shared among all these competing uses. California found that due to limited irrigation water, at best biomass could provide 18% of transportation fuel, but recommended that a quarter of the biomass be allocated to utilities to generate electricity (Youngs and Somerville 2013).

Since trucks and rail are the basis of civilization as we know it, all, most of this biomass ought to be converted to #2 diesel to keep trucks and locomotives running. Instead, 40% of the corn crop is wasted on ethanol for non-essential cars. Diesel engines can’t burn ethanol or diesohol. Currently biodiesel is just 1 percent of total diesel production by volume, with soybeans making up 57 percent of that feedstock.

Oil is a biofuel, but nonrenewable since it took Mother Nature millions of years to brew with 196,000 pounds of plants per gallon, which is equivalent to cramming 40 acres of wheat into your gas tank every 20 miles (Dukes).

And therein lies the rub. It takes enormous amounts of biomass to make liquid fuels. Biomass doesn’t scale up enough to replace even a small fraction of what we use. Only 1% of total U.S. energy is provided by 40% of the corn crop (NAS 2014).

Europe’s International Energy Agency has a target of 150 EJ/year from biomass. To do that would require 15 billion metric tons of plant biomass taking up 200 billion cubic meters (bcm). But only 2 billion metric tons of rice, wheat, soybeans, corn, and other grains and oil seeds with a volume of 2.75 bcm were produced in 2010, and only 6.2 bcm of coal and 5.7 bcm of oil were moved in 2008, orders of magnitude less than 200 bcm (Richard).

If you yanked every plant in America out of the ground, roots and all, and burned them to create energy, far more energy than converting plants to biofuels, you’d get 94 exajoules (EJ), less than the 105 EJ of fossil fuels Americans use per year (Patzek 2005), and we could all pretend we lived on Mars.

David Pimentel doubts that cellulosic biomass will ever be able to provide enough liquid fuel because “Green plants collect and convert less than 0.1% of the incident sunlight into plant matter [Pimentel and Patzek 2008, Pimentel et al 2006, Pimentel et al 2012]. In the United States all green plants collectively produce biomass equivalent to about 53 exajoules of energy per year from sunlight, only about half of our total fossil energy use. Hence even if we were able to use all agricultural, forest , grassland and aquatic plants, with no production of food or fiber, at an impossible 100% efficiency this would be barely enough energy to displace oil (Hall 2011).

To make B5 diesel fuel (5% biodiesel) would require 64% of the soybean crop and 71,875 square miles of land (Borgman 2007), so 20 times as many soybeans are needed to make B100 taking almost half of the land in the contiguous 48 states. The best, most productive land east of the Mississippi that can grow soybeans with rainfall.

Giampietro (2009) calculates that we’d need 558 billion liters of ethanol, which would require 1500 million tonnes of corn, which is six times the entire production of corn in the U.S. in 2003. This would generate 500 million tonnes of Dried Distillers Grain (DDG) byproduct, 10 times more than the entire consumption of high protein commercial feeds — 51 million tonnes in 2003. Pro-ethanol scientists add DDG as a positive net energy gain, when in fact it will take a huge amount of energy to dispose of most of this environmental pollution, only a small percent of which can be eaten by lifestock, and only carried so far or the diesel fuel used to transport it is larger than the energy contained in the DDG..

Over the past 2,000 years we’ve reduced the living biomass on the planet by 45% — from about 1,000 billion tons (35 zeta joules (ZJ) = joules × 1021) to 550 billion tons (19.2 ZJ), with 11% of that consumed just since 1900, and we’re continuing to burn it up at a rate of 1.5 billion tons per year (Smil, Houghton). And this at a time when biomass isn’t our major energy source, as it was in all previous civilizations.

I ought to stop right here; obviously turning biomass into fuel is an unworkable idea, but many readers will imagine that even a little biofuel will help, even if we can’t produce enough to live at the God-like level we do now. Just one of many silver bullets.

But even a little won’t help, because making biofuels is a loss of net energy, using more fossil fuel than the energy contained in the biofuel, as I explain in Part 3. Even those who have found a positive Energy Return on Invested (EROI) have come up with an average EROI of 1.2, and it takes an EROI of at least 7 (Weissbach et al. (2013), 11 (Murphy 2011), or 14 (Lambert et al. 2014) to maintain civilization as we know it.

But people argue endlessly about EROI because of the boundaries (do you include the energy to make the tractor that planted the corn or not?), so I don’t spend as much time on this as I could.

What really upsets me beyond scaling up and EROI is the enormous ecological damage, which I cover in Parts 2 and 4.

Part 2. The Dirt on Dirt.

Ethanol is an agribusiness get-rich-quick scheme that will bankrupt our topsoil.

It’s already happening: Landowners around the world are now engaged in such an orgy of soil destruction that, according to the UN’s Food and Agriculture Organization, the world on average has just 60 more years of growing crops (Monbiot 2015).

Nineteenth century western farmers converted their corn into whiskey to make a profit (Rorabaugh 1979). The energy to haul moonshine is a tiny fraction of the energy to haul corn to distant cities after all, more of a positive EROI if you will.

Archer Daniels Midland (ADM), a large grain processor, came up with a similar scheme in the 20th century; ethanol. But ethanol was a product in search of a market, so ADM spent three decades relentlessly lobbying for ethanol to be used in gasoline. Today ADM makes record profits from ethanol sales and government subsidies (Barrionuevo 2006).

The Department of Energy hopes to have biomass supply 5% of the nation’s power, 20% of transportation fuels, and 25% of chemicals by 2030. These combined goals are 30% of the current petroleum consumption (DOE Biomass Plan, DOE Feedstock Roadmap).

Fuels made from biomass are a lot like the nuclear powered airplanes the Air Force tried to build from 1946 to 1961, for billions of dollars. They never got off the ground. The idea was interesting – atomic jets could fly for months without refueling. But the lead shielding to protect the crew and several months of food and water was too heavy for the plane to take off. The weight problem, the ease of shooting this behemoth down, and the consequences of a crash landing were so obvious, it’s amazing the project was ever funded, let alone kept going for 15 years.

Biomass fuels have equally obvious and predictable reasons for failure. Odum says that time explains why renewable energy provides such low energy yields compared to non-renewable fossil fuels. The more work left to nature, the higher the energy yield, but the longer the time required. Although coal and oil took millions of years to form into dense, concentrated solar power, all we had to do was extract and transport them (Odum 1996)

With every step required to transform a fuel into energy, there is less and less energy yield. For example, to make ethanol from corn grain, which is how all ethanol is made now, corn is first grown to develop hybrid seeds, which next season are planted, harvested, delivered, stored, and preprocessed to remove dirt. Dry-mill ethanol is milled, liquefied, heated, saccharified, fermented, evaporated, centrifuged, distilled, scrubbed, dried, stored, and transported to customers (McAloon 2000).

Fertile soil will be destroyed if crops and other “wastes” are removed to make cellulosic ethanol.

“We stand, in most places on earth, only six inches from desolation, for that is the thickness of the topsoil layer upon which the entire life of the planet depends” (Sampson 1981).

Farming always ruins soils eventually; civilizations fail after about 1500 years because of this

Productivity drops off sharply when topsoil reaches 6 inches or less. Historically, it takes most civilizations 1500 years to exhaust their soils. Then they collapse (Montgomery 2007).

Loss of topsoil has been a major factor in the fall of civilizations (Sundquist 2005 Chapter 3, Lowdermilk 1953, Perlin 1991, Ponting 1993). You end up with a country like Iraq, formerly Mesopotamia, where 75% of the arable farm land is now a salty desert.

Industrial farming methods are likely to crash our civilization in 150 years or less. Not only do these methods remove trees for miles, allowing topsoil to blow and wash away, they are very heavy and can permanently compact the soil. This is one of the reasons they can’t be powered by batteries, which would have to weigh nearly as much as the tractor to move it an inch.

Peak Phosphate will also cause civilization to collapse

Industrial farming is also limited by phosphate, which scientists estimate will last from 40 to 400 more years. Most of the phosphate left is in Morocco, 75%, hardly the most stable region in the world. There are other considerations than geological depletion that can affect how long phosphate lasts (Walan 2014).

Phosphate is mined from phosphate rock. Because the world’s grasslands are losing phosphorus through various processes, it’s estimated that phosphate application on grassland will have to quadruple between 2005 and 2050, to increase production by the 80% expected to be necessary over that time period.

In total, it’s thought that phosphorus production will have to more than double by 2050 compared to 2005, just to keep up with demand. It’s not clear how much further phosphate rock production can grow. Some estimates are that phosphate rock production will peak by 2027, even as depletion of our soils will merely get worse.

Why can’t we produce more biomass?

The real challenge with bioenergy, according to Timothy Searchinger, a research scholar at Princeton University, is that photosynthesis is extremely inefficient. “If you’re really lucky you get half a percent of the solar energy transformed into plant biomass.”

But we don’t even get half of a percent. Calculating efficiency in terms of how much energy is available from the biofuel versus how much energy was in the sunlight hitting the plants used to produce the biofuel, the efficiency of ethanol made from corn is only about 0.03 percent.

More about soil erosion

Long before there was “Peak Oil”, there was “Peak Soil”. Iowa has some of the best topsoil in the world. In the past century, half of it’s been lost, from an average of 18 to 10 inches deep (Pate 2004, Klee 1991), or even more according to Needelman (2013) — in the 20th century, farming has caused soil to go from 14 to 18 inches down to 6 to 8 inches.

20 to 40 pounds of soil are eroded for every gallon of ethanol produced (Institute of Medicine 2014).

Productivity drops off sharply when topsoil reaches 6 inches or less, the average crop root zone depth (Sundquist 2005).

Crop productivity continually declines as topsoil is lost and residues are removed. (Al-Kaisi May 2001, Ball 2005, Blanco-Canqui 2006, BOA 1986, Calviño 2003, Franzleubbers 2006, Grandy 2006, Johnson 2004, Johnson 2005, Miranowski 1984, Power 1998, Sadras 2001, Troeh 2005, Wilhelm 2004).

On over half of America’s best crop land, the erosion rate is 27 times the natural rate, 11,000 pounds per acre (NCRS 2006). The natural, geological erosion rate is about 400 pounds of soil per acre per year (Troeh 2005). Some is due to farmers not being paid enough to conserve their land, but most is due to investors who farm for profit. Erosion control cuts into profits.

Globally, Professor John Crawford of the University of Sydney estimates that soil is being lost 10 to 40 times faster than it’s being geologically replenished, leaving around 60 years of topsoil left to be mined for food. Already 40% of agricultural soil is classed as degraded or seriously degraded — 70% of the topsoil gone (WEC).

Farming methods have increased soil erosion to rates much greater than soil is formed — it can take up to 1,000 years to form 1 centimeter (0.4 inch) of soil (Wall and Six 2015). Wall and Six go on to say that “Human activities have transformed soils,lands, and regions with long-lasting effects that include desertification, decreased organic matter in soils, altered biodiversity, and changed biogeochemical and hydrological cycles. As a result, the land available for food production is shrinking, irreversibly in some cases. Converting cropland to biofuel systems and urban centers is having the same effect.”

Iowa State scientists tracking soil erosion after storms believe that the true erosion rate is many times higher than estimates from the Department of Agriculture’s National Resource Conservation Department (EWG)

Erosion is happening 10 to 20 times faster than the rate topsoil can be formed by natural processes (Pimentel 2006). That might make the average person concerned. But not the USDA — they’ve defined erosion as the average soil loss that could occur without causing a decline in long term productivity.

Troeh (2005) believes that the tolerable soil loss (T) value is set too high, because it’s based only on the upper layers — how long it takes subsoil to be converted into topsoil. T ought to be based on deeper layers – the time for subsoil to develop from parent material or parent material from rock. If he’s right, erosion is even worse than NCRS figures.

We’ve come a long way since the 1930’s in reducing erosion, but that only makes it more insidious. Erosion is very hard to measure — very little soil might erode for years, and then tons per acre blown or washed away in an extreme storm just after harvest, before a cover crop has had a chance to protect the soil. We need better ways of measuring and monitoring erosion, since estimates wildly differ (Trimble 2000).

Well, all right, I’ve hammered you over the head with erosion enough already, let’s move on to my favorite part of soil: the living creatures within it.

Soil Science 101 – There Is No “Waste” Biomass

Erosion removes the most fertile parts of the soil (USDA-ARS) by removing the trillions of creatures who once lived there.

When you feed the soil with organic matter, you’re not feeding plants; you’re feeding the biota in the soil. Underground creatures and fungi break down fallen leaves and twigs into microscopic bits that plants can eat, and create tunnels air and water can infiltrate. In nature, there are no elves feeding (fertilizing) the wild lands. When plants die, they’re recycled into basic elements and become a part of new plants. It’s a closed cycle. There is no bio-waste.

Soil creatures and fungi act as an immune system for plants against diseases, weeds, and insects – when this living community is harmed by agricultural chemicals and fertilizers, even more chemicals are needed in an increasing vicious cycle (Wolfe 2001).

There’s so much life in the soil, there can be 10 “biomass horses” underground for every horse grazing on an acre of pasture (Hemenway 2000). The June 2004 issue of Science calls soils “The Final Frontier”. Just a tiny pinch of earth could have 10,000 different species (Wardle 2004) — millions of creatures, most of them unknown. If you dove into the soil and swam around, you’d be surrounded by thousands of miles of thin strands of mycorrhizal fungi that help plant roots absorb more nutrients and water (Pennisi 2004). As you swam along, plant roots would tower above you like trees as you wove through underground skyscrapers.

Plants and creatures underground need to drink, eat, and breathe just like we do. An ideal soil is half rock, and a quarter each water and air. When tractors plant and harvest, they crush the life out of the soil, as underground apartments collapse 9/11 style. The tracks left by tractors in the soil are the erosion route for half of the soil that washes or blows away (Wilhelm 2004).

Corn and soy are especially harmful because they need a lot of water, fertilizer, agrichemicals, resulting in eutrophication. They are also among the crops most vulnerable to soil erosion.

- Row crops like corn and soy cause 50 times more soil erosion than sod crops (Sullivan 2004) or more (Al-Kaisi 2000), because the soil between rows can wash or blow away. If corn is planted with last years corn stalks left on the ground (no-till), erosion is less of a problem, but only about 20% of corn is grown no-till. Soy is usually grown no-till, but has insignificant residues to harvest for fuel.

- Corn uses more water than most crops. It takes about 118 gallons of water to produce 1 pound of corn, and 21 pounds of corn to make a gallon of ethanol. So you’d need about 2.5 trillion gallons of water to make a billion gallons of ethanol, more than all the water southern California receives from the Sacramento-San Joaquin Delta (Sacramento Bee 2007).

- In the life cycle of making corn ethanol, 99% of the water used grows the corn, only 1% is used in the industrial process. From seed to fuel, this requires 1,500 gallons of water per gallon of ethanol. In the industrial phase, cellulosic ethanol requires twice as much water. California and other states that grow crops with irrigation rather than rain water would require displacing food crops with energy crops, and there already isn’t enough water for food, people, and fisheries (Fingerman 2008).

- Corn uses more agrichemicals, and fertilizer than most crops (Padgitt 2000, Pimentel 2003). Due to high corn prices, continuous corn (corn crop after corn crop) is increasing, rather than rotation of nitrogen fixing (fertilizer) and erosion control sod crops with corn.

- Corn plants are amazingly good at absorbing nitrogen from the soil and storing it in the grain itself. Thus, it takes a lot of fertilizer to replace that nitrogen, but if it rains after the application of fertilizer, down the Mississippi it goes. A large part of the problem with runoff of nitrogen (and soil) is because corn is known as a “leaky crop” because nutrients inevitably leak out because the land is bare half of each year (Institute of Medicine 2014).

- The government has studied the effect of growing continuous corn, and found it increases eutrophication by 189%, global warming by 71%, and acidification by 6% (Powers 2005). Production of ethanol results in 8 grams of nutrients for every gallon of ethanol that ends up in the Gulf of Mexico (Institute of Medicine 2014).

- Farmers want to plant corn on highly-erodible, water protecting, or wildlife sustaining Conservation Reserve Program land. Farmers are paid not to grow crops on this land. But with high corn prices, farmers are now asking the Agricultural Department to release them from these contracts so they can plant corn on these low-producing, environmentally sensitive lands (Tomson 2007).

- Crop residues are essential for soil protection, nutrition, water retention, and soil carbon. Making cellulosic ethanol from corn residues — the parts of the plant we don’t eat (stalk, roots, and leaves) – removes water, carbon, and nutrients (Nelson, 2002, McAloon 2000, Sheehan, 2003).

In summary, Tegtmeier (2004) writes that these practices lead to lower crop production and ultimately deserts. Growing plants for fuel will accelerate the already unacceptable levels of topsoil erosion, soil carbon and nutrient depletion, soil compaction, water retention, water depletion, water pollution, air pollution, eutrophication, destruction of fisheries, siltation of dams and waterways, salination, loss of biodiversity, and damage to human health.

Why are soil scientists absent from the biofuels debate?

I asked 35 soil scientists why topsoil wasn’t part of the biofuels debate. These are just a few of the responses from the ten who replied to my off-the-record poll (no one wanted me to quote them, mostly due to fear of losing their jobs):

- ”I have no idea why soil scientists aren’t questioning corn and cellulosic ethanol plans. Quite frankly I’m not sure that our society has had any sort of reasonable debate about this with all the facts laid out. When you see that even if all of the corn was converted to ethanol and that would not provide more than 20% of our current liquid fuel use, it certainly makes me wonder, even before considering the conversion efficiency, soil loss, water contamination, food price problems, etc.”

- Biomass production is not sustainable. Only business men and women in the refinery business believe it is.

- “Should we be using our best crop land to grow gasohol and contribute further to global warming? What will our children grow their food on?”

- “As agricultural scientists, we are programmed to make farmer’s profitable, and therefore profits are at the top of the list, and not soil, family, or environmental sustainability”.

- “Government policy since WWII has been to encourage overproduction to keep food prices down (people with full bellies don’t revolt or object too much). It’s hard to make a living farming commodities when the selling price is always at or below the break even point. Farmers have had to get bigger and bigger to make ends meet since the margins keep getting thinner and thinner. We have sacrificed our family farms in the name of cheap food. When farmers stand to make few bucks (as with biofuels) agricultural scientists tend to look the other way”.

- You are quite correct in your concern that soil science should be factored into decisions about biofuel production. Unfortunately, we soil scientists have missed the boat on the importance of soil management to the sustainability of biomass production, and the long-term impact for soil productivity.

This is not a new debate. Here’s what scientists had to say in the past

Removing “crop residues…would rob organic matter that is vital to the maintenance of soil fertility and tilth, leading to disastrous soil erosion levels. Not considered is the importance of plant residues as a primary source of energy for soil microbial activity. The most prudent course, clearly, is to continue to recycle most crop residues back into the soil, where they are vital in keeping organic matter levels high enough to make the soil more open to air and water, more resistant to soil erosion, and more productive” (Sampson 1981).

“…Massive alcohol production from our farms is an immoral use of our soils since it rapidly promotes their wasting away. We must save these soils for an oil-less future” (Jackson 1980).

Gasohol was made so poorly in the 80’s that the name was changed to ethanol.

What the USDA knew about continuous corn in 1911:

“When the rich, black, prairie corn lands of the Central West were first broken up, it was believed that these were … inexhaustible lands … So crop after crop of corn was planted on the same fields. There came a time, however, after 15 or 20 years, when the crop did not respond to cultivation; the yields fell off and the lands that once produced 60-70 bushels per acre annually dropped to 25 to 30 bushels.

… With the passing years, the soil became more compact, droughts were more injurious, and the soil baked harder and was more difficult to handle. Continuous corn culture has no place in progressive farming…it is a shortsighted policy and is suicidal on lands that have been long under cultivation” (Smith 1911).

We’ve known for a long that biofuels can’t replace fossil fuels, because past civilizations with just millions, not billions of people fell when they cut their forests down to make warships, metals, bricks, ceramics, and other products, they fell (Perlin 2005).

Civilizations in the past could not expand their carrying capacity with just their own agricultural production. Growth depended on conquering other nations and enslaving their people, taking their surplus food, forests, gold, and other wealth. With these new resources, the army could be expanded and more nations conquered. When an empire could expand no more, it collapsed. This comes about partly because the government ignores the rural communities they depend on, and they resent not being part of the resource redistribution of conquered nations and the over-taxation and confiscation of food by the central authorities, leaving them perpetually on the verge of starvation. So when the barbarians invaded the Roman Empire, many rural areas welcomed them, and joined them in battles, yet another reason (Tainter 1988).

Sam Brody (1945) wrote: “It is said that we should use alcohol and vegetable oils after the petroleum energy has been exhausted. This reminds one of Marie Antoinette’s advice to the Paris poor to eat cake when they had no bread”.

What Admiral Hyman G. Rickover knew in 1957 (Energy Resources & Our Future):

Farm wastes may be more urgently needed to fertilize the soil than to fuel machines. Wood fuel and farm wastes are dubious as substitutes because of growing food requirements to be anticipated. Land is more likely to be used for food production than for tree crops.

Deforestation not only lessens the energy base but has a further disastrous effect: lacking plant cover, soil washes away, and with soil erosion the nutritional base is reduced as well.

Another cause of declining civilization comes with pressure of population on available land. A point is reached where the land can no longer support both the people and their domestic animals.

There is absolute consensus among energy analysts that fossil fuels made modern civilization possible

According to Giampietro (2008): “In the community of energy analysts, there is absolute consensus that the major discontinuity in all major trends of human development — population, energy consumption per capita, technological progress associated with the Industrial Revolution was generated by the extremely high quality of fossil energy as a primary energy source, compared with biomass. The tremendousadvantage of fossil energy over alternative energy sources is easy to explain: when considering the energetic costs of the production of producing oil it’s almost nothing, the oil is already there” (unlike biofuels, which need to be produced). Fossil fuels are a primary energy source, from which secondary energy gasoline and other products are produced. Biofuels are not a primary source of energy, they need to be produced. Therefore, the only energy carrier that could replace fossil fuels is a primary energy source of similar performance in terms of useful work per unit of primary energy consumed. Anything less than that will cause a significant downturn.

Natural Gas in Agriculture

“Fertilizer energy” is 28% of the energy used in agriculture (Heller, 2000). Fertilizer uses natural gas both as a feedstock and the source of energy to create the high temperatures and pressures necessary to coax inert nitrogen out of the air (nitrogen is often the limiting factor in crop production).

Fertilizers only replace nutrition. They don’t provide the ecosystem services that organic matter does. Organic matter is known as “waste” in the biofuels industry.

Organic matter slows erosion and fixes carbon in the soil. Dead plants and the soil biota that feed on them create channels that let air and water get to plant roots, which breathe and drink just like we do. The soil retains water, helping plants get through droughts.

Organic matter provides food for the soil biota, which provide an immune system for plants. The mycorrhizal fungi in the soil provide plants extra nutrients and water in exchange for sugars.

Fertilizer not only provides no ecosystem services, it harms the ecosystem. Fertilizer disables or kills some of the creatures in the soil web, which increases the need for agrichemicals in an increasingly vicious cycle.

Fertilizers increase global warming, acid rain, and eutrophication.

You can grow tomatoes on rocks if you dump enough fertilizer on them. But doing so depletes the soil, we mine it when we do this.

Fertilizer represents 28% of the energy used in agriculture. So let me get this straight. Fertilizers are made from and with natural gas which we’re dumping on crops to grow them for biofuel. We’re going to take the biomass waste away, which means we’ll have to add even more fertilizer. How, exactly, does that lessen our dependence on fossil fuels?

OK, one good thing, sort of. Fertilizer is part of the green revolution that made it possible for the world’s population to grow from 1 billion to 7.1 billion people (Smil 2000, Fisher 2001). Up to 6 billion are alive who otherwise wouldn’t be. But natural gas is a finite resource on a finite planet, and is not easily imported, and despite all the hype about fracking in the United States, natural gas production is likely to peak 2015 to 2018 (Powers 2013). Discontinuities clearly lie ahead.

Our national security is at risk as we deplete our aquifers and become dependent on unstable foreign states to provide us with increasingly expensive fertilizer. Between 1995 and 2005 we increased our fertilizer imports by more than 148% for Anhydrous Ammonia, 93% for Urea (solid), and 349 % of other nitrogen fertilizers (USDA ERS). Removing crop residues will require large amounts of imported fertilizer from potential cartels, potentially so expensive farmers won’t sell crops and residues for biofuels.

Improve national security and topsoil by returning residues to the land as fertilizer. We are vulnerable to high-priced fertilizer imports or “food for oil”, which would greatly increase the cost of food for Americans. Return crop residues to the soil to provide organic fertilizer, don’t increase the need for natural gas fertilizers by removing crop residues to make cellulosic biofuels.

Part 3. The Poop on Ethanol:

Energy Returned on Energy Invested (EROEI)

To understand the concept of EROEI, imagine a magician doing a variation on the rabbit-out-of-a-hat trick. He strides onstage with a rabbit, puts it into a top hat, and then spends the next five minutes pulling 100 more rabbits out. That is a pretty good return on investment!

Oil was like that in the beginning: one barrel of oil energy was required to get 100 more out, an Energy Returned on Energy Invested of 100:1.

When the biofuel magician tries to do the same trick decades later, he puts the rabbit into the hat, and pulls out only one pooping rabbit. The excrement is known as byproduct or coproduct in the ethanol industry.

Studies that show a positive energy gain for ethanol would have a negative return if the byproduct were left out (Farrell 2006). Here’s where byproduct comes from: if you made ethanol from corn in your back yard, you’d dump a bushel of corn, two gallons of water, and yeast into your contraption. Out would come 18 pounds of ethanol, 18 pounds of CO2, and 18 pounds of byproduct – the leftover corn solids.

Patzek and Pimentel believe you shouldn’t include the energy contained in the byproduct, because you need to return it to the soil to improve nutrition and soil structure (Patzek June 2006). Giampetro believes the byproduct should be treated as a “serious waste disposal problem and … an energy cost”, because if we supplied 10% of our energy from biomass, we’d generate 37 times more livestock feed than is used (Giampetro 1997), “making it a serious environmental problem, a pollutant on the sink side, to which energy analysts need to associate an energetic and economic cost rather than a positive return.

Giampetro (2009) also says that if corn co-products are going to be included, and the huge land demand and ecological destruction ignored, then the far more energetically valuable co-products of gasoline production and their very small land footprint need to be thrown into the balance, instead of just their CO2 emissions. Scientists with a secret agenda of boosting the EROI of biofuels skew their results by “ignoring the co-products of gasoline production from oil, reducing the overall output/input ratio of gasoline).”

It’s even worse than he realized – Giampetro didn’t know most of this “livestock feed” can’t be fed to livestock because it’s too energy and monetarily expensive to deliver – especially heavy wet distillers byproduct, which is short-lived, succumbing to mold and fungi after 4 to 10 days. Also, byproduct is a subset of what animals eat. Cattle are fed byproduct in 20% of their diet at most. Iowa’s a big hog state, but commercial swine operations feed pigs a maximum of 5 to 10% byproduct (Trenkle 2006; Shurson 2003).

And if the EROEI of biofuels are indeed positive, as some scientists claim, especially those funded by the National Corn Growers Association, why isn’t ethanol used to fuel the tractors that plant and harvest, the trucks that carry biomass to the biorefinery, and final delivery of biofuels to the customer?

Because corn and soy crops have higher erosion rates than most crops, their eroded sediment fills up reservoirs, shortening their life-span and the time dams can store water and generate electricity. Yet the energy of the hydropower lost to siltation, to build a new dam sooner than its lifespan, the energy to remediate flood damage, the energy to dredge dams, agricultural drainage ditches, harbors, and navigation channels, aren’t considered in EROEI calculations. Or the energy needed to clean up the agrichemicals that get into soil and water.

Farm runoff of nitrogen fertilizers has contributed to the pollution and hypoxia (low oxygen) of rivers and lakes across the country and the 8,000 square mile dead zone in the Gulf of Mexico. Yet the cost of the lost shrimp and fisheries and increased cost of water treatment are not subtracted from the EROEI of ethanol.

Worst of all, the EROEI of ethanol is 1.2:1 or 1.2 units of energy out for every unit of energy in, a gain of “.2” at best, many scientists have found ethanol to have a negative EROI – more fossil fuel energy used than the energy contained in the biofuel.

By the way, the “1” in “1.2” represents the liquid ethanol. What is the “.2” then? It’s the byproduct, like the rabbit feces after a rabbit dines (though that has more energy than corn byproduct. Rabbits are copraphagous – they eat their feces to get any energy they left in it after digestion).

So you have no ethanol at all for your car, because the liquid “1” needs to be used to make more ethanol. That leaves you with just the “.2” — a bucket of byproduct to feed your horse. You do have a horse, don’t you? If horses are like cattle, then you can only use your byproduct for one-fifth of their diet, so you’ll need four supplemental buckets of hay from your back yard to feed him that you should avoid using fossil fuels to grow or harvest since that will certainly be more energy than contained in the DDG.

Byproduct can be burned, but it takes a significant amount of energy to dry it out, and requires additional handling and equipment — even more energy. More money can be made selling it wet to the cattle industry, which is hurting from the high price of corn. But delivering it takes energy, and that isn’t subtracted from the EROI either. Yet the transportation fraction of the energy required to grow and deliver energy crops to a biorefinery is 7 to 26% for lignocellulosic crops such as switchgrass, miscanthus, and other forage or crop residues (Richard).

Byproduct should be put back into the ground to improve soil nutrition, soil structure, and lessen erosion so future generations won’t starve to death, not sold for short-term profit and fed to cattle who aren’t biologically adapted to eating corn.

The boundaries of what is included in EROEI calculations are kept as narrow as possible to reach positive results.

Researchers who find a positive EROEI for ethanol have not accounted for all of the energy inputs. For example, Shapouri admits the “energy used in the production of … farm machinery and equipment…, and cement, steel, and stainless steel used in the construction of ethanol plants, are not included”. (Shapouri 2002). Or they assign overstated values of ethanol yield from corn (Patzek Dec 2006). Many, many, other inputs are left out.

Patzek and Pimentel have compelling evidence showing that about 30 percent more fossil energy is required to produce a gallon of ethanol than you get from it. Their papers are published in peer-reviewed journals where their data and methods are public, unlike many of the positive net energy results.

Infrastructure. Current EROEI figures don’t take into account the delivery infrastructure that needs to be built. There are 850 million combustion engines in the world today. Just to replace half the 245 million cars and light trucks in the United States with E85 vehicles will take 12-15 years, It would take over $544 million dollars of delivery ethanol infrastructure (Reynolds 2002 case B1) and $5 to $34 billion to revamp 170,000 gas stations nationwide (Heinson 2007).

The EROEI of oil when we built most of the infrastructure in this country was about 100:1, and it’s about 25:1 worldwide now. Even if you believe ethanol has a positive EROEI, you’d probably need at least an EROEI of at least 5 to maintain modern civilization (Hall 2003). A civilization based on ethanol’s “.2” rabbit poop would only work for coprophagous rabbits.

Of the four articles that showed a positive net energy for ethanol in Farrells 2006 Science article, three were not peer-reviewed. The only positive peer-reviewed article (Dias De Oliveira, 2005) states “The use of ethanol as a substitute for gasoline proved to be neither a sustainable nor an environmentally friendly option” and the “environmental impacts outweigh its benefits”. Dias De Oliveria concluded there’d be a tremendous loss of biodiversity, and if all vehicles ran on E85 and their numbers grew by 4% per year, by 2048, the entire country, except for cities, would be covered with corn.

Part 4. Do you want to eat, drive, or drink?

There’s an ethanol gold rush going on. More than half the best farmland in the United States is leased by investors. Two-thirds or more of the farmland in the corn and soy growing states of Iowa, Minnesota, Illinois, and Indiana is rented (65, 74, 84, and 86% respectively).

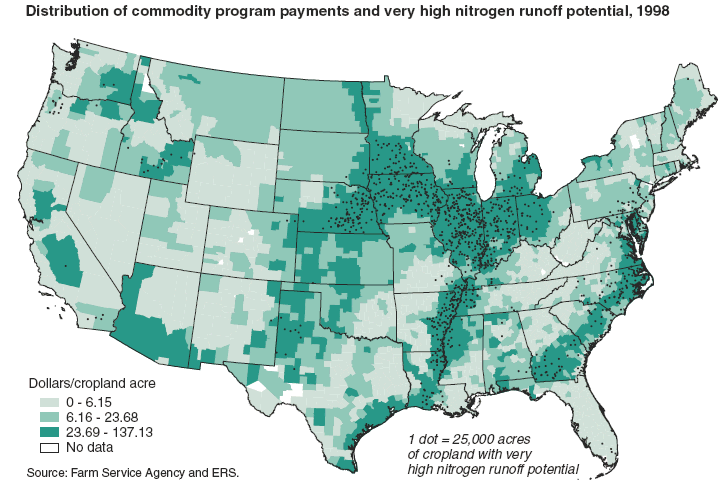

Notice that these mostly investor-owned corn and soybean growing states, are mainly red in the map below. Red represents the areas where farms have the highest erosion rates.

Owners seeking short-term profits have far less incentive than farmers who work their land to preserve soil and water. They don’t adopt as long-term conservation measures as farm owner-operators do (ERS 1999).

The dark green areas of this map represent where the highest crop subsidy payments go and where the highest nitrogen runoff rates are. Notice that again, these areas correspond with investor-owned farmland. Commodity payments were meant to be a safety net, but the money ends up being used to buy and apply excess fertilizer, which gets into rivers, lakes, and oceans (Redlin 2007).

Excessive atmospheric nitrogen pollution from industrial farming practices threatens plant diversity. About a quarter of 15,000 sites across the United States are likely to lose species as a result of nitrogen pollution (Simkin 2016).

http://www.iwla.org/publications/agriculture/Farm_Bill_2007_WEB.pdf

Water Pollution

Soil erosion is a serious source of water pollution, since it causes runoff of sediments, nutrients, salts, eutrophication, and chemicals that have had no chance to decompose into streams. This increases water treatment costs, increases health costs, kills fish with insecticides that work their way up the food chain (Troeh 2005).

Ethanol plants pollute water. They generate 13 liters of wastewater for every liter of ethanol produced, yet more energy and a lowering of the overall EROEI (Pimentel March 2005)

Water depletion

Biofuel factories use a huge amount of water – four gallons for every gallon of ethanol produced. Despite 30 inches of rain per year in Iowa, there may not be enough water for corn ethanol factories as well as people and industry. Drought years will make matters worse (Cruse 2006).

The facilities that produce ethanol require high-purity water, which is largely taken from confined aquifers, even in the rain-fed Midwest. Given the use of the water from the aquifers, there is clearly a certain amount of unsustainable pumping taking place, according to Jerald Schnoor. In Iowa, for example, there are a large number of ethanol production plants, and the Cambrian- Ordovician aquifer, known as the Jordan aquifer, has been pumped down by 150 or 200 feet, so eventually future generations will not be able to use that aquifer (Institute of Medicine 2014).

Fifty percent of Americans rely on groundwater (Glennon 2002), and in many states, this groundwater is being depleted by agriculture faster than it is being recharged. This is already threatening current food supplies (Giampetro 1997). In some western irrigated corn acreage, groundwater is being mined at a rate 25% faster than the natural recharge of its aquifer (Pimentel 2003).

According to Vaclav Smil, “Corn irrigation is already the single largest user of underground water in the basin, and expansion of the corn-growing area into drier western fringes, or further intensification of corn production, would create additional demand for the mining of the already receding Ogallala aquifer”

Biodiversity

To understand the earth’s overall capacity to produce bioenergy, it is useful to think in terms of its net primary productivity (NPP), which is “the amount of photosynthetic biomass available for exploitation by the biosphere.” The earth’s NPP is staggeringly large—about 56 gigatonnes of carbon dioxide per year. It turns out that humans already use about 30% of NPP for food, fabrics, construction, and other uses. Any increase in the use of biofuels will require an increase in the amount of the earth’s NPP being appropriated for human use. And of course 100% of this NPP is already being used—if not by humans, then by various animals, fungi, bacteria, and other forms of life—so any increase in the human use of the NPP will take away from other ecosystem processes [and drive other species to extinction] (Institute of Medicine 2014).

Every acre of forest and wetland converted to crop land decreases soil biota, insect, bird, reptile, and mammal biodiversity.

Honeybees. Springtime die-offs of honeybees from corn coated with insecticides was discovered in January 2012. Bees are critical for pollinating food crops — these deaths are a part of the mysterious colony collapse disorder (Tapparo).

Part 5. Biodiesel: Can we eat enough French Fries?

The idea we could run our economy on discarded fried food grease is very amusing. For starters, you’d need to feed 7 million heavy diesel trucks getting less than 8 mpg. Seems like we’re all going to need to eat a lot more French Fries, but if anyone can pull it off, it would be Americans. Spin it as a patriotic duty and you’d see people out the door before the TV ad finished, the most popular government edict ever.

Scale. Where’s the Soy? Biodiesel is not ready for prime time. In 2006, John Deere was working on fuel additives and technologies that would allow their equipment to burn more than 5% accredited biodiesel (made to ASTM D6751 specifications – vegetable oil does not qualify). In 2016 John Deere allows up to B20:

“All John Deere engines can use biodiesel blends. B5 blends are preferred, but concentrations up to 20 percent (B20) can be used providing the biodiesel used in the fuel blend meets the standards set by the American Society of Testing Materials (ASTM) D6751 or European Standard (EN) 14214.

John Deere engines with exhaust filters should not use biodiesel blends above B20. Concentrations above B20 may harm the engine’s emissions control system. Specific risks include, but are not limited to, more frequent regeneration, soot accumulation, and increased intervals for ash removal. For these engines, John Deere-approved fuel conditioners containing detergent/dispersant additives are required when using B20, and recommended when using lower biodiesel blends.”

52 billion gallons of diesel fuel are consumed a year in the United States, but only 75 million gallons of biodiesel were produced – two-tenths of one percent of what’s needed. To get the country to the point where gasoline was mixed with 5 percent biodiesel would require 64 percent of the soybean crop and 71,875 square miles of land (Borgman 2007), an area the size of the state of Washington. Soybeans cause even more erosion than corn.

But not to worry, a lot is being grown in Brazil, where the Amazon rainforest is being cut down to grow it.

Biodiesel shortens engine life. Currently, biodiesel concentrations higher than 5 percent can cause “water in the fuel due to storage problems, foreign material plugging filters…, fuel system seal and gasket failure, fuel gelling in cold weather, crankcase dilution, injection pump failure due to water ingestion, power loss, and, in some instances, can be detrimental to long engine life” (Borgman 2007). Biodiesel also has a short shelf life and it’s hard to store – it easily absorbs moisture (water is a bane to combustion engines), oxidizes, and gets contaminated with microbes. It increases engine NOx emissions (ozone) and has thermal degradation at high temperatures (John Deere 2006).

On the cusp of energy descent, we can’t even run the most vital aspect of our economy, agricultural machines, on “renewable” fuels. John Deere tractors can run on no more than 5% accredited biodiesel (Borgman 2007). Perhaps this is unintentionally wise – biofuels have yet to be proven viable, and mechanization may not be a great strategy in a world of declining energy.

Soybeans are the main source of biodiesel, but the food and soap/detergent industries also buy soybeans, driving the price up. There is limited land to grow soybeans and other oily crops on, which limit production, according to DOE and USDA. As a result, experts believe that the total production capacity of biodiesel is ultimately limited compared with other alternative fuels (USGAO).

Part 6. If we can’t drink and drive, then burn baby burn.

Energy Crop Combustion.

Wood is a crop, subject to the same issues as corn, and takes a lot longer to grow. Burning wood in your stove at home delivers far more energy than the logs would if converted to biofuels (Pimentel 2005). Wood was scarce in America when there were just 75 million people. Electricity from biomass combustion is not economic or sustainable.

The immediate crisis is the need for a liquid fuel to substitute for oil or we can’t plant and harvest crops or transport goods, which would cause civilization to collapse. The only liquid fuels possible are liquified coal, Natural Gas Liquids, or biofuels. Burning biomass doesn’t do that — it only generates electricity.

Combustion pollution is expensive to control. Some biomass has absorbed heavy metals and other pollutants from sources like coal power plants, industry, and treated wood. Combustion can release chlorinated dioxins, benzofurans, polycyclic aromatic hydrocarbons, cadmium, mercury, arsenic, lead, nickel, and zinc.

Combustion contributes to global warming by adding nitrogen oxides and the carbon stored in plants back into the atmosphere, as well as removes agriculturally essential nitrogen and phosphate (Reijnders 2006)

EROEI in doubt. Combustion plants need to produce, transport, prepare, dry, burn, and control toxic emissions. Collection is energy intensive, requiring some combination of bunchers, skidders, whole-tree choppers, or tub grinders, and then hauling it to the biomass plant. There, the feedstock is chopped into similar sizes and placed on a conveyor belt to be fed to the plant. If biomass is co-fired with coal, it needs to be reduced to ¼ inch or less, and the resulting fly ash may not be marketable to the concrete industry (Bain 2003). Any alkali or chlorine released in combustion gets deposited on the equipment, reducing overall plant efficiencies, as well as accelerating corrosion and erosion of plant components, requiring high replacement and maintenance energy.

Processing materials with different physical properties is energy intensive, requiring sorting, handling, drying, and chopping. It’s hard to optimize the pyrolysis, gasification, and combustion processes if different combustible fuels are used. Urban waste requires a lot of sorting, since it often has material that must be removed, such as rocks, concrete and metal. The material that can be burned must also be sorted, since it varies from yard trimmings with high moisture content to chemically treated wood.

Biomass combustion competes with other industries that want this material for construction, mulch, compost, paper, and other profitable ventures, often driving the price of wood higher than a wood-burning biomass plant can afford. Much of the forest wood that could be burned is inaccessible due to a lack of roads.

Efficiency is lowered if material with a high water content is burned, like fresh wood. Different physical and chemical characteristics in fuel can lead to control problems (Badger 2002). When wet fuel is burned, so much energy goes into vaporizing the water that very little energy emerges as heat, and drying takes time and energy.

Material is limited and expensive. California couldn’t use crop residues due to low bulk density. In 2000, the viability of California biomass enterprise was in serious doubt because the energy to produce biomass was so high due to the small facilities and high cost of collecting and transporting material to the plants (Bain 2003).

Scale. The largest biomass plants burn wood and rarely reach even 50 MW in size. Coal plants are often 1,500 MW. This is because of “the high cost of transporting low-energy-content biomass. A maximum 40-mile radius for the resource base is typical. And as a consequence of these sizes, biopower plants are typically less efficient than fossil fuel plants are; the cost of implementing high-efficiency technologies is not economically justified at small scales.” (NAS 2009)

Part 7. The problems with Cellulosic Ethanol could drive you to drink.

Many plants want animals to eat their seed and fruit to disperse them. Some seeds only germinate after going through an animal gut and coming out in ready-made fertilizer. Seeds and fruits are easy to digest compared to the rest of the plant, that’s why all of the commercial ethanol and biodiesel are made from the yummy parts of plants, the grain, rather than the stalks, leaves, and roots.

But plants don’t want to be entirely devoured. They’ve spent hundreds of millions of years perfecting structures that can’t easily be eaten. Be thankful plants figured this out, or everything would be mown down to bedrock.

If we ever did figure out how to break down cellulose in our back yard stills, it wouldn’t be long before the 6.5 billion people on the planet destroyed the grasslands and forests of the world to power generators and motorbikes (Huber 2006)

Don Augenstein and John Benemann, who’ve been researching biofuels for over 30 years, are skeptical as well. According to them, “…severe barriers remain to ethanol from lignocellulose. The barriers look as daunting as they did 30 years ago”.

Benemann says the EROEI can be easily determined to be about 5 times as much energy required to make cellulosic ethanol than the energy contained in the ethanol.

The success of cellulosic ethanol depends on finding or engineering organisms that can tolerate extremely high concentrations of ethanol. Augenstein argues that this creature would already exist if it were possible. Organisms have had a billion years of optimization through evolution to develop a tolerance to high ethanol levels (Benemann 2006). Someone making beer, wine, or moonshine would have already discovered this creature if it could exist.

The range of chemical and physical properties in biomass, even just corn stover (Ruth 2003, Sluiter 2000), is a challenge. It’s hard to make cellulosic ethanol plants optimally efficient, because processes can’t be tuned to such wide feedstock variation.

It’s May 2016, and there’s still no commercial-scale cellulosic ethanol, yet 16 billion gallons were supposed to be produced by 2022 (Rapier 2016).

Perhaps this is why British Petroleum has backed out of their $350 million dollar partnership with the University of California Energy Biosciences Institute. BP’s decision targets one area of research in particular—lignocellulosic (LC) biofuel technology and announced a company-wide policy to shift away from research in LC fuels. Skepticism about commercial biofuels persists. A new report from the World Resources Institute, an environmental think tank, said that “Even assuming large increases in efficiency, the quest for bioenergy at a meaningful scale is both unrealistic and unsustainable.” And that claims about the benefits of biofuels have been greatly exaggerated. Especially when it comes the impossibly enormous amount of plant-based materials needed to make biofuels, which would consume valuable agricultural land that would be put to better use growing crops to feed the planet’s surging population (Neumann 2015).

In 2015, Texas-based KiOR filed for bankruptcy. To help pay off the enormous debt of their failed Columbus, Mississippi biofuel plant which cost $230 million to construct, its equipment is being sold. Taxpayers are unlikely to be reimbursed the $79 million that the state OF Mississippe lent and the $1.1 million owed in property taxes. The plant failed in turning wood chips into a crude oil substitute because of problems that plagued its production process. The state of Mississippi is also trying to recover its debt through KiOR’s bankruptcy case in Delaware, and through a lawsuit that claims KiOR investor Vinod Khosla and others knew KiOR had limited chances for success but defrauded Mississippi into loaning $75 million to the company anyway (AP 2015).

Green Fuel Nordic is trying to convert wood to pyrolysis fuels, which has proven difficult so far because wood has tar, which is a gummy residue of long-chain molecules that are hard to refine. Another concern is oxygen, abundant in all biomass which causes problems when oxygen reacts with pyrolysis oil and forms organic acids that can corrode refinery equipment severely (Krieger 2014).

Where will the Billion Tons of Biomass for Cellulosic Fuels Come From?

Not from Algae, that’s for sure. There are dozens of reasons why algae will never be a source of biofuel.

The government believes there is a billion tons of biomass “waste” to make cellulosic biofuels, chemicals, and generate electricity with.

The United States lost 59,334,800 million acres of cropland between 1982 and 2010 (NCRS 2013). At that rate, all of the cropland will be gone in 170 years, and 900 years from now all remaining rural non-federal acres will be buried by development:

| Non-federal Land USA | Cropland Acres | Prime Cropland acres (a) | Developed Land | CRP 1992 Acres | Pasture Acres |

| 1982 | 420,227,000 | 227,682,600 | 70,000,000 | 34,091,100 | 131,533,300 |

| 2010 | 360,892,200 | 201,864,200 | 113,000,000 | 26,610,100 | 120,449,900 |

| acres lost | 59,334,800 | 25,818,400 | 43,000,000 | 7,481,000 | 11,083,400 |

| percent | -14% | -11% | 61% | -22% | -8.40% |

| Non-federal Land USA | Range Acres | Water Erosion tons/ acre (b) | Wind Erosion tons/ acre (c) | Total Rural non-federal acres |

| 1982 | 419,127,000 | 4.37 | 3.63 | 1,424,008,100 |

| 2010 | 409,092,700 | 3.08 | 2.34 | 1,377,424,600 |

| acres lost | 10,034,300 | 46,583,500 | ||

| percent | -2.40% | -3.3 |

(a) page 111

(b) page 129 Table 13. Estimated average annual sheet and rill erosion on non-Federal rural land, by State and year Tons per acre per year

(c) page 147 Table 14. Estimated average annual wind erosion on non-Federal rural land, by State and year Tons per acre per year

There isn’t enough biomass to replace 30% of our petroleum use. The potential biomass energy is miniscule compared to the fossil fuel energy we consume every year, about 105 exa joules (EJ) in the USA. If you burned every living plant and its roots, you’d have 94 EJ of energy and we could all pretend we lived on Mars. Most of this 94 EJ of biomass is already being used for food and feed crops, and wood for paper and homes. Sparse vegetation and the 30 EJ in root systems are economically unavailable – leaving only a small amount of biomass unspoken for (Patzek June 2006).

Over 25% of the “waste” biomass is expected to come from 280 million tons of corn stover. Stover is what’s left after the corn grain is harvested. Another 120 million tons will come from soy and cereal straw (DOE Feedstock Roadmap, DOE Biomass Plan).

There isn’t enough no-till corn stover to harvest. The success of biofuels depends on corn residues. About 80% of farmers disk corn stover into the land after harvest. That renders it useless — the crop residue is buried in mud and decomposing rapidly.

Only the 20 percent of farmers who farm no-till will have stover to sell. The DOE Billion Ton vision assumes all farmers are no-till, 75% of residues will be harvested, and fantasy corn and wheat yields 50% higher than now are reached (DOE Billion Ton Vision 2005). But none of this corn stover should be harvested because corn loses more soil than any other crop grown (Pimentel 2007).

Many tons will never be available because farmers won’t sell any, or much of their residue (certainly not 75%). “Many predictions imagine that farmers will be willing to sell cellulosic biomass for the order of $40 or $50 a ton. Today, they can get $200 a ton for hay.” Given the difference, it is unlikely that many farmers will switch over from hay to cellulosic biomass (Institute of Medicine 2014)

Many more tons will be lost due to drought, rain, or loss in storage.

Only half a percent of a plant can be harvested sustainably every year. Plants only fix a tiny part of solar energy into plant matter annually — about one-tenth to one-half of one percent new growth in temperate climates.

To prevent erosion, you could only harvest 51 million tons of corn and wheat residues, not 400 million tons (Nelson, 2002). Other factors, like soil structure, soil compression, water depletion, and environmental damage weren’t considered. Fifty one million tons of residue could make about 3.8 billion gallons of ethanol, less than 1% of our energy needs.

Using corn stover is a problem, because corn, soy, and other row crops cause 50 times more soil erosion than sod crops (Sullivan 2004) or more (Al-Kaisi 2000), and corn also uses more water, insecticides and fertilizers than most crops (Pimentel 2003)

The amount of soy and cereal straw (wheat, oats, etc) is insignificant. It would be best to use cereal grain straw, because grains use far less water and cause far less erosion than row crops like corn and soybeans. But that isn’t going to happen, because the green revolution fed billions more people by shortening grain height so that plant energy went into the edible seed, leaving little straw for biofuels. Often 90% of soybean and cereal straw is grown no-till, but the amount of cereal straw is insignificant and the soybean residues must remain on the field to prevent erosion

Energy Crops

Energy crops are grown specifically for their fuel value. Tall perennial grasses such as switchgrass and miscanthus are being proposed as potential energy crops. Although grasses cause less erosion and need less fertilizer, they still suffer from the problems that all plants have:

- Most non-food energy crops require as much water as corn, per unit weight (Pimentel 2007). And they need a lot of water to be processed into a biofuel. The Great Plains are the most likely place energy crops would be planted. Yet the Ogallala aquifer is depleting fast and won’t replenish until after the next ice age. Where’s the water to process tall grass prairies into biofuels going to come from?

- Plants have low density compared to fossil fuels. If you try to pelletize or compact them, that takes energy, and they’re still low density. Hay bales are like mattresses – you can only get so many on a truck, and you can’t force them into a pipeline, which would be far less expensive.

- The larger the biorefinery, the better the economies of scale. Biofuels need to be created at a large scale for any hope of a positive energy balance and enough purity to be used in combustion engines, which are extremely fine-tuned for diesel or gasoline, fuel injection, etc.

- Plants aren’t concentrated – they grow diffusely and require a great deal of energy to harvest and deliver to the refinery.

- Plants are hard to store. They rot and turn into mulch or can catch on fire. Storing them wet adds weight, leading to higher transportation costs and high water use.

- All plants succumb to pests and disease. Miscanthus is from China, but eventually pests will evolve to dine upon it, especially if grown in monocrops.

Poor, erodible land. There aren’t enough acres of land to grow significant amounts of energy crops. Potential energy crop land is usually poor quality or highly erodible land that shouldn’t be harvested. Farmers are often paid not to farm this unproductive land. Many acres in switchgrass are being used for wildlife and recreation.

Few suitable bio-factory sites. Biorefineries can’t be built just anywhere – very few sites could be found to build switchgrass plants in all of South Dakota (Wu 1998). Much of the state didn’t have enough water or adequate drainage to build an ethanol factory. The sites had to be on main roads, near railroad and natural gas lines, out of floodplains, on parcels of at least 40 acres to provide storage for the residues, have electric power, and enough biomass nearby to supply the plant year round.

No energy crop farmers or investors. Farmers won’t grow switchgrass until there’s a switchgrass plant. Machines to harvest and transport switchgrass efficiently don’t exist yet (Barrionuevo 2006). The capital to build switchgrass plants won’t materialize until there are switchgrass farmers. Since “ethanol production using switchgrass required 50% more fossil energy than the ethanol fuel produced” (Pimentel 2005), investors for these plants will be hard to find.

Energy crops are subject to Liebig’s law of the minimum too. Switchgrass may grow on marginal land, but it hasn’t escaped the need for minerals and water. Studies have shown the more rainfall, the more switchgrass you get, and if you remove switchgrass, you’re going to need to fertilize the land to replace the lost biomass, or you’ll get continually lower yields of switchgrass every time you harvest the crop (Vogel 2002).

Bioinvasive Potential. These fast-growing disease-resistant plants are potentially bioinvasive, another kudzu. Bioinvasion costs our country billions of dollars a year (Bright, 1998). Johnson grass was introduced as a forage grass and it’s now an invasive weed in many states. Another fast-growing grass, Miscanthus, from China, is now being proposed as a biofuel. It’s been described as “Johnson grass on steroids” (Raghu 2006). These foreign grasses do quite well because they don’t have any pests, yet.

Sugar cane: too little to import. Brazil uses oil for 90% of their energy, and 17 times less oil (Jordan 2006). Brazilian ethanol production in 2003 was 3.3 billion gallons, about the same as the USA in 2004, or 1% of our transportation energy. Brazil uses 85% of their cane ethanol, leaving only 15% for export.

Sugar Cane: can’t grow it here. Although we grow some sugar cane despite tremendous environmental damage (WWF) in Florida thanks to the sugar lobby, we’re too far north to grow a significant amount of sugar cane or other fast growing C4 plants.

Sugar cane has been touted as an “all you need is sunshine” plant. But according to the FAO, the nitrogen, phosphate, and potassium requirements of sugar cane are roughly similar to maize (FAO 2004).

Wood ethanol is an energy sink. Ethanol production using wood biomass required 57% more fossil energy than the ethanol fuel produced (Pimentel 2005).

Wood is a nonrenewable resource. Old-growth forests had very dense wood, with a high energy content, but wood from fast-growing plantations is so low-density and low calorie it’s not even good to burn in a fireplace. These plantations require energy to plant, fertilize, weed, thin, cut, and deliver. The trees are finally available for use after 20 to 90 years – too long for them to be considered a renewable fuel (Odum 1996). Nor do secondary forests always come back with the vigor of the preceding forest due to soil erosion, soil nutrition depletion, and mycorrhizae destruction (Luoma 1999).

There’s not enough wood to fuel a civilization of 300 million people. Over half of North America was deforested by 1900, at a time when there were only 75 million people (Williams 2003). Most of this was from home use. In the 18th century the average Northeastern family used 10 to 20 cords per year. At least one acre of woods is required to sustainably harvest one cord of wood (Whitney 1994).

Energy crop limits. Energy crops may not be sustainable due to water, fertilizer, and harvesting impacts on the soil (DOE Biomass Roadmap 2005). Like all other monoculture crops, ultimately yields of energy crops will be reduced due to “pest problems, diseases, and soil degradation” (Giampetro, 1997).

Energy crop monoculture. The “physical and chemical characteristics of feedstocks vary by source, by year, and by season, increasing processing costs” (DOE Feedstock Roadmap). That will encourage the development of genetically engineered biomass to minimize variation. Harvesting economies of scale will mean these crops will be grown in monoculture, just as food crops are. That’s the wrong direction – to farm with less energy there’ll need to be a return to rotation of diverse crops, and composted residues for soil nutrition, pest, and disease resistance.

A way around this would be to spend more on researching how cellulose digesting microbes tackle different herbaceous and woody biomass. The ideal energy crop would be a perennial, tall-grass prairie / herbivore ecosystem (Tilman 2006). Tilman recommends harvesting “all grassland in the U.S. for ethanol but neglects to report that 100 million cattle, 7 million sheep, and 4 million horses are currently grazing on this grass!” (Pimentel 2007).

Antibiotic Resistance. You are probably aware that a crisis looms ahead as more and more microbes become antibiotic resistant. A major way this is happening is from the healthy animals in factory farms, who consume 80% of all antibiotics to gain more weight and prevent disease. They are also getting antibiotics from ethanol production. A byproduct is produced called Dried Distillers Grain (DDG), which is often contaminated with Lactobacilli which thrive in the ethanol mash it comes from. So ethanol producers add antibiotics like penicillin and erythromycin to the fermentation tanks. When factory farm animals eat DDG, they are also eating illegal antibiotics (Olmstead 2012, Laskawy 2012, McKenna 2012).

Farmers aren’t Stupid: They won’t sell their residues

Farmers are some of the smartest people on earth or they’d soon go out of business. They have to know everything from soil science to commodity futures.

Crop production is reduced when residues are removed from the soil. Why would farmers want to sell their residues?

Erosion, water, compression, nutrition. Harvesting of stover on the scale needed to fuel a cellulosic industry won’t happen because farmers aren’t stupid, especially the ones who work their own land. Although there is a wide range of opinion about the amount of residue that can be harvested safely without causing erosion, loss of soil nutrition, and soil structure, many farmers will want to be on the safe side, and stick with the studies showing that 20% (Nelson, 2002) to 30% (McAloon et al., 2000; Sheehan, 2003) at most can be harvested, not the 75% agribusiness claims is possible. Farmers also care about water quality (Lal 1998, Mann et al, 2002). And farmers will decide that permanent soil compression is not worth any price (Wilhelm 2004). As prices of fertilizer inexorably rise due to natural gas depletion, it will be cheaper to return residues to the soil than to buy fertilizer.

Residues are a headache. The further the farmer is from the biorefinery or railroad, the slimmer the profit, and the less likely a farmer will want the extra headache and cost of hiring and scheduling many different harvesting, collection, baling, and transportation contractors for corn stover.

Residues are used by other industries. Farm managers working for distant owners are more likely to sell crop residues since they’re paid to generate profits, not preserve land. But even they will sell to the highest bidder, which might be the livestock or dairy industries, furfural factories, hydromulching companies, biocomposite manufacturers, pulp mills, or city dwellers faced with skyrocketing utility bills, since the high heating value of residue has twice the energy of the converted ethanol.

Investors aren’t stupid either. If farmers can’t supply enough crop residues to fuel the large biorefinery in their region, who will put up the capital to build one?

Can the biomass be harvested, baled, stored, and transported economically?

Plants are closer to cotton candy than rocks. The oil to harvest, bale, deliver, clean, and store these straw pillows is likely to use more energy than the cellulosic fuels created.

Harvesting. Sixteen ton tractors harvest corn and spit out stover. Many of these harvesters are contracted and will continue to collect corn in the limited harvest time, not stover. If tractors are still available, the land isn’t wet, snow doesn’t fall, and the stover is dry, three additional tractor runs will mow, rake, and bale the stover (Wilhelm 2004). This will triple the compaction damage to the soil (Troeh 2005), create more erosion-prone tire tracks, increase CO2 emissions, add to labor costs, and put unwanted foreign matter into the bale (soil, rocks, baling wire, etc).

So biomass roadmaps call for a new type of tractor or attachment to harvest both corn and stover in one pass. But then the tractor would need to be much larger and heavier, which could cause decades-long or even permanent soil compaction. Farmers worry that mixing corn and stover might harm the quality of the grain. And on the cusp of energy descent, is it a good idea to build an even larger and more complex machine?

If the stover is harvested, the soil is now vulnerable to erosion if it rains, because there’s no vegetation to protect the soil from the impact of falling raindrops. Rain also compacts the surface of the soil so that less water can enter, forcing more to run off, increasing erosion. Water landing on dense vegetation soaks into the soil, increasing plant growth and recharging underground aquifers. The more stover left on the land, the better.

Baling. The current technology to harvest residues is to put them into bales of hay. Hay is a dangerous commodity — it can spontaneously combust, and once on fire, can’t be extinguished, leading to fire loss and increased fire insurance costs. Somehow the bales have to be kept from combusting during the several months it takes to dry them from 50 to 15 percent moisture. A large, well drained, covered area is needed to vent fumes and dissipate heat. If the bales get wet they will compost (Atchison 2004).

Baling was developed for hay and has been adapted to corn stover with limited success. Biorefineries need at least half a million tons of biomass on hand to smooth supply bumps, much greater than any bale system has been designed for. Pelletization is not an option, it’s too expensive. Other options need to be found. (DOE Feedstock Roadmap)

To get around the problems of exploding hay bales, wet stover could be collected. The moisture content needs to be around 60 percent, which means a lot of water will be transported, adding significantly to the delivery cost.

25% of switchgrass and corn stover are lost during the harvesting and baling as well as a great deal of energy in each step (Ruth 2013).

| Step | Equipment | DM tons/ acre SW | Energy used Mbtu/ DM ton SW | DM tons/ acre CS | Energy used Mbtu/ DM ton CS |

| 1 | 180 HP tractor & 15-ft flail shredder w/Windrower | NA | NA | 3 | 50.1 |

| 2 | self-propelled Windrower with Disc Header | 5 | 30.9 | NA | NA |

| 3 | 275 HP tractor & large square baler | 4 | 61.2 | 2.4 | 61.2 |

| 4 | self-propelled Loader | 4 | 13.7 | 2.4 | 13.7 |

| 5 | self-propelled Stacker | 4 | 25.4 | 2.4 | 25.4 |

| 6 | Weather protection | 4 | 0 | 2.4 | 0 |

| 7 | self-propelled loader | 3.8 | 12.4 | 2.28 | 12.4 |

| Total 24% loss of switchgrass and corn stover | -1.2 | 143.6 | -0.72 | 162.8 |

Storage. Stover needs to be stored with a moisture content of 15% or less, but it’s typically 35-50%, and rain or snow during harvest will raise these levels even higher (DOE Feedstock Roadmap). If it’s harvested wet anyhow, there’ll be high or complete losses of biomass in storage (Atchison 2004).

After catastrophic fires, the pulp industry learned to only use wet feedstock. If residues are stored wet, as in ensilage, a great deal of R&D will be needed to see if there are disease, pest, emission, runoff, groundwater contamination, dust, mold, or odor control problems. The amount of water required is unknown. The transit time must be short, or aerobic microbial activity will damage it. At the storage site, the wet biomass must be immediately washed, shredded, and transported to a drainage pad under a roof for storage, instead of baled when drier and left at the farm. The wet residues are heavy, making transportation costlier than for dry residues, perhaps uneconomical. It can freeze in the winter making it hard to handle. If the moisture is too low, air gets in, making aerobic fermentation possible, resulting in molds and spoilage.

Delivery to the biorefinery and preprocessing