Preface. Also see related article Limits to Growth? 2016 United Nations report provides best evidence yet.

Nichols (2015) below shows that climate change is already affecting harvests of the world’s top 10 crops that comprise 83% of our calories: barley, cassava, maize, oil palm, rapeseed, rice, sorghum, soybean, sugarcane and wheat. So though the article below says we’re approaching peak food, to some extent we’re already there (Deepak 2019).

What does “Peak Food” mean?

“Peak food refers to the point at which the global agricultural system reaches maximum production capacity, after which output begins to decline. This decline is caused by a variety of factors, including soil degradation, loss of biodiversity, climate change, and water scarcity.

One of the main drivers of peak food is the loss of fertile land. As urbanization and industrialization increase, fertile land is being converted to non-agricultural uses at an alarming rate. This is further compounded by the degradation of soil due to overuse of chemical fertilizers and pesticides, as well as the loss of biodiversity due to monoculture farming practices.

Climate change is also a major contributor to peak food, as rising temperatures and extreme weather events are making it increasingly difficult to grow crops in many regions around the world. In addition, water scarcity is becoming a major issue as droughts and over-extraction of groundwater are making it difficult to irrigate crops (FI 2015).”

And now the weeds are winning as they develop resistance to herbicides, and can wipe out half or even all of a field (Main 2024). Likewise with pesticides. A. L. Melander published research in 1914 on how insects develop resistance to pesticides.

Our world in data (2022) points out that “Humans have been reshaping the planet’s land for millennia by clearing wildlands to grow crops and raise livestock. As a result, humans have cleared one-third of the world’s forests and two-thirds of wild grasslands since the end of the last ice age. This has come at a huge cost to the planet’s biodiversity. In the last 50,000 years – and as humans settled in regions around the world – wild mammal biomass has declined by 85%. Expanding agriculture has been the biggest driver of the destruction of the world’s wildlands. This expansion of agricultural land has now come to an end. After millennia, we have passed the peak, and in recent years global agricultural land use has declined.”

And then concludes that since we are producing more food than ever, this can continue! Ignoring aquifer depletion, melting glaciers, topsoil erosion which the United Nations says means just an average of 60 more years of food production, dependence on finite fossil fuels to make the fertilizer that feeds 4 billion of us.

Wouldn’t it be easier to encourage fewer children and tax breaks for those who comply? to make birth control and abortion easy to get and free? I guess the plan is for starvation and civil wars to keep the financial system that depends on endless growth to keep going.

Alice Friedemann www.energyskeptic.com Author of Life After Fossil Fuels: A Reality Check on Alternative Energy; When Trucks Stop Running: Energy and the Future of Transportation”, Barriers to Making Algal Biofuels, & “Crunch! Whole Grain Artisan Chips and Crackers”. Women in ecology Podcasts: WGBH, Financial Sense, Jore, Planet: Critical, Crazy Town, Collapse Chronicles, Derrick Jensen, Practical Prepping, Kunstler 253 &278, Peak Prosperity, Index of best energyskeptic posts

***

On about 23 million acres, or roughly two-thirds of Illinois, farmers grow corn and soybeans, spraying every acre with herbicides. But these chemicals, which allow one plant species to live unbothered across inconceivably vast spaces, are no longer stopping all the weeds from growing.

Since the 1980s, more and more plants have evolved to become immune to the biochemical mechanisms that herbicides leverage to kill them. This herbicidal resistance threatens to decrease yields—out-of-control weeds can reduce them by 50% or more, and extreme cases can wipe out whole fields.

At worst, it can even drive farmers out of business. It’s the agricultural equivalent of antibiotic resistance, and it keeps getting worse. East of Champaign-Urbana, there is a soybean field overgrown with dark-green, spiky plants that rise to chest height. Water hemp. Despite being sprayed at least once.

Water hemp can infest just about any kind of crop field. It grows an inch or more a day, and produces hundreds of thousands of seeds. Native to the Midwest, it has burst forth in much greater abundance over the last few years, because it has become resistant to seven different classes of herbicides. Season-long competition from water hemp can reduce soybean yields by 44% and corn yields by 15%, according to Purdue University Extension.

Two different groups of herbicides still usually work against water hemp. But cases of resistance to both are cropping up more and more.

According to Ian Heap, a weed scientist who runs the International Herbicide-Resistant Weed Database, there have been well over 500 unique cases of the phenomenon in 273 weed species and counting. Weeds have evolved resistance to 168 different herbicides and 21 of the 31 known “modes of action,” which means the specific biochemical target or pathway a chemical is designed to disrupt. Some modes of action are shared by many herbicides.

One of the most wicked weeds in the South, one that plagues Steckel and his colleagues, is a rhubarb-red-stemmed cousin to water hemp known as Palmer amaranth (Amaranthus palmeri). Populations of the weeds have been found that are impervious to nine different classes of herbicides. The plant can grow more than two inches a day to reach eight feet in height and dominate entire fields. Originally from the desert Southwest, it boasts a sturdy root system and can withstand droughts. If rainy weather or your daughter’s wedding prevents you from spraying it for a couple of days, you’ve probably missed your chance to control it chemically.

Palmer amaranth “will zero your yield out,” Hager says. Several other weeds, including Italian ryegrass and a tumbleweed called kochia, are inflicting real pain on the farmers in the South and the West, particularly in wheat and sugar beet fields.

Before World War II, farmers generally used cultivators such as plows and harrows to remove weeds and break up the ground. Or they did it by hand—like my mother, who remembers hoeing weeds in cornfields as a kid growing up on an Indiana farm. That changed with the advent of synthetic pesticides and herbicides, which farmers started using in the 1950s. By the 1970s, some of the first examples of resistance appeared. By the early 1980s, Heap and his colleague Stephen Powles had discovered populations of ryegrass (Lolium rigidum) that were resistant to the most commonly used herbicides, known as ACCase inhibitors, spreading throughout southern Australia. Within a few years, this species had become resistant to yet another class, called ALS-inhibiting herbicides.

Monsanto began marketing genetically engineered crops including corn and soybeans that were resistant to the commercial weed killer Roundup, the active ingredient of which is called glyphosate. Monsanto portrayed these “Roundup-ready” crops, and the ability to spray whole fields with glyphosate, as a virtual silver bullet for weed control.Glyphosate quickly became one of the most widely used agricultural chemicals, and it remains so today. It was so successful, in fact, that research and development on other new herbicides withered: No major commercial herbicide appears likely to hit the market anytime soon that could help address herbicide resistance on a grand scale.

Monsanto claimed it was “highly unlikely” that glyphosate-resistant weeds would become a problem. There were, of course, those who correctly predicted that such a thing was inevitable—among them Jonathan Gressel, a professor emeritus at the Weizmann Institute of Science in Rehovot, Israel, who has been studying herbicides since the 1960s.

Stanley Culpepper, a weed scientist at the University of Georgia, confirmed the first case of Roundup resistance in Palmer amaranth in 2004. Resistance rapidly spread. Both Palmer amaranth and water hemp produce male and female plants, the former of which produce pollen that can blow long distances on the wind to pollinate the latter. This also gives the plant a lot of genetic diversity, which allows it to evolve faster—all the better for herbicide resistance to develop and spread. These super-weeds sowed chaos throughout the state.

Weeds have developed surprising ways to get around chemical control. One 2009 study published in the Proceedings of the National Academy of Sciences showed that a mutation in the Palmer amaranth genome allowed the plant to make more than 150 copies of the gene that glyphosate targets.

Another bizarre way resistance can arise in that species is via structures called extrachromosomal circular DNA, strands of genetic material including the gene target for glyphosate that exist outside of nuclear chromosomes. This gene can be transferred via wind-blown pollen from plants with this adaptation.

But scientists are increasingly finding metabolic resistance in weeds, where plants have evolved mechanisms to break down just about any foreign substance—including a range of herbicides.

Let’s say a given herbicide worked on a population of water hemp one year. If any plants “escape,” or survive, and make seeds, their offspring could possess metabolic resistance to the herbicides used.

There’s evidence of resistance developing to both of the chemical groups that have replaced or been mixed with Roundup to kill this weed: an herbicide called glufosinate and a pair of substances known as 2,4-D and dicamba. These two would normally kill many crops, too, but there are now millions of acres of corn and soy genetically modified to be impervious. So essentially the response has been to throw more chemicals at the problem. “If it worked last year, if you have metabolic resistance there’s no guarantee it’s going to work this year,” Hager says.

Many of these herbicides can harm the environment and have the potential to harm human health, says Nathan Donley, the environmental health science director at the Center for Biological Diversity, which is based in Tucson, Arizona. Paraquat, for example, is a neurotoxic chemical banned in more than 60 countries (it’s been linked to conditions like Parkinson’s), Donley says, but it’s being used more and more in the United States. 2,4-D, one of the active ingredients in Agent Orange, is a potential endocrine disruptor, and exposure to it is correlated with increased risk of various cancers. Glyphosate is listed as a probable human carcinogen by an agency within the World Health Organization and has been the subject of tens of thousands of lawsuits worth tens of billions. Atrazine can stick around in groundwater for years and can shrink testicles and reduce sperm count in certain fish, amphibians, reptiles, and mammals.

Replacing glyphosate with herbicides like 2,4-D and dicamba, which are generally more toxic, “is definitely a step in the wrong direction,” Donley says.

Looking for solutions

It’s not just chemicals. Weeds can become resistant to any type of control method. In a classic example from China, a weed called barnyard grass evolved over centuries to resemble rice and thus evade hand weeding.

Because weeds can evolve relatively quickly, researchers recommend a wide diversity of control tactics. Mixing two herbicides with different modes of action can sometimes work, though that’s not the best for the environment or the farmer’s wallet.

Rotating the plants that are grown helps, as does installing winter cover crops and, above all, not using the same herbicide in the same way every year.

Farms have ballooned in size over the last couple of decades, as a result of rural flight, labor costs, and the advent of chemicals and genetically modified crops that allowed farmers to quickly apply herbicides over massive areas to control weeds. This has led to a kind of sinister simplification in terms of crop diversity, weed control practices, and the like. And the weeds have adjusted.

On the one hand, it’s understandable that farmers often do the cheapest thing they can to control weeds, to get them through the year. But resistance is a medium- to long-term problem running up against a system of short-term thinking and incentives. Farmers are generally informed and worried about herbicide resistance but are constrained by a variety of factors that prevent them from really heading it off. The farm is too big to economically control weeds without spraying in a single shot, some farmers say, while others lack the labor, financing, or time. Agriculture needs to embrace a diversity of weed control practices, Owen says.

[ Many of the proposed solutions below are far too high-tech to survive or build post fossil fuels ]

Fennimore developed a prototype that injects steam into the ground, killing weeds within several inches of the entry point. This has proved around 90% effective, and he’s used it in fields growing lettuce, carrots, and onions. But it is not exactly quick: It takes two or three days to treat a 10-acre block.

Many other nonchemical means of control are gaining traction in vegetables and other high-value crops. Eventually, if the economics and logistics work out, these could catch on in row crops, those planted in rows that can be tilled by machinery.

A company called Carbon Robotics, for example, produces an AI-driven system called the LaserWeeder that, as the name implies, uses lasers to kill weeds. It is designed to pilot itself up and down crop rows, recognizing unwanted plants and vaporizing them with one of its 30 lasers. LaserWeeders are now active in at least 17 states, according to the company.

You can also shock weeds by using electricity, and several apparatuses designed to do so are commercially available in the United States and Europe. A typical design involves the use of a height-adjustable copper boom that zaps weeds it touches. The most obvious downside with this method is that the weeds usually have to be taller than the crop. By the time the weeds have grown that high, they’ve probably already caused a decline in yield.

Weed seed destructors are another promising option. These devices, commonly used in Australia and catching on a bit in places like the Pacific Northwest, grind up and kill the seeds of weeds as wheat is harvested.

Another classic approach is crop rotation—switching between crops with different life cycles, management practices, and growth patterns is a mainstay of agriculture, and it helps prevent weeds from becoming accustomed to one cropping system. Yet another option is to put in a winter cover crop that helps prevent weeds from getting established.

***

The days of assuming natural resources can be swapped to solve shortages – corn for oil, soy for beef – may be over.

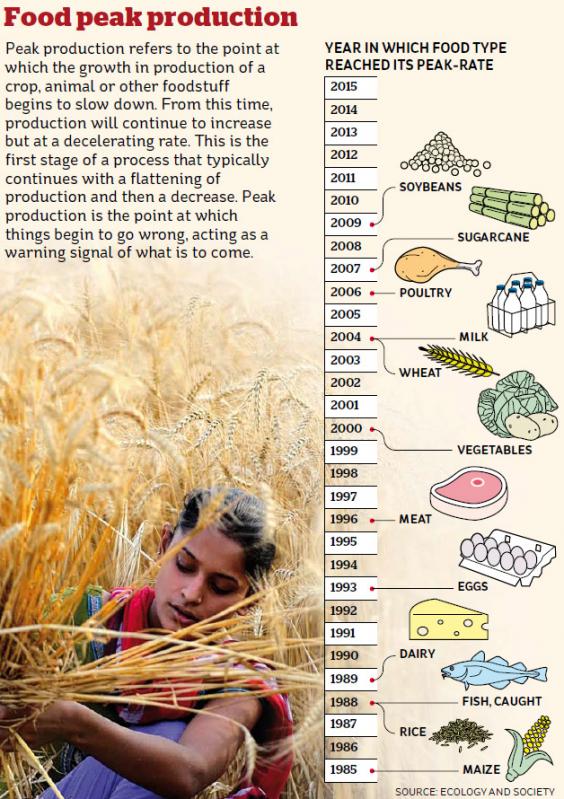

An international group of scientists demonstrate that many key resources have peaked in productivity, pointing to the sobering conclusion that “renewable” is not synonymous with “unlimited.”

“People often talk about substitution. If we run out of one resource, we just substitute another. But if multiple resources are running out, we’ve got a problem,” said Jack Liu, director of MSU’s Center for Systems Integration and Sustainability.

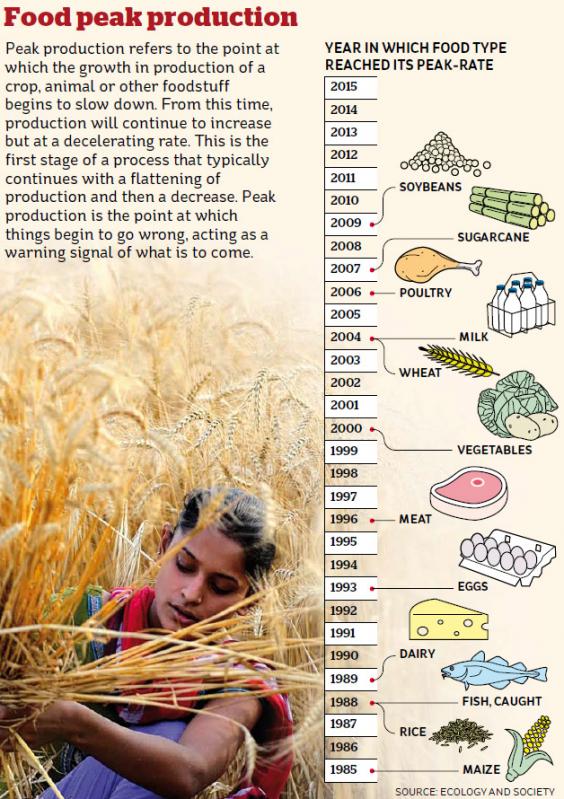

The research team discovered not only that 20 resources had a peak-year but also that for 16 of the 20 resources with a peak year, the peak year lay between 1988 and 2008 – a narrow range in the history of mankind. The annual growth rate of 18 of these renewable resources – for example, increase in meat production or fish catch – peaked around 2006.

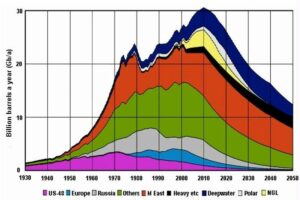

[ My note: it’s interesting that the master resource, oil, which makes all others possible, peaked in 2005-2006 (conventional oil that is, where 90% of petroleum comes from). ]

Here are several reasons why many of the peak years occurred during the same time period or synchronized:

- Multiple resources such as land, food and energy, are consumed simultaneously to meet different needs of rapidly growing populations and diet changes worldwide.

- Producing one resource needs other resources, i.e.food production needs land, energy and water.

- Producing resources creates pollution, which exacerbates resource shortages.

- Extracting less accessible resources results in an increased ecological and economic cost per unit extracted, thus lowering the availability of the remaining resources.

Renewable resources become scarcer. The authors were able to illustrate this using various examples: The maximum global growth rate in crop yields for soybeans was in 2009, for milk it was 2004, for eggs it was 1993 and for the fish caught it was 1988. Data from other studies confirm these results. For example, the crop yield per area with corn, wheat, soy and rice on more than a quarter of the farming area around the world is stagnating or decreasing.

Bawden, T. January 2015. Have we reached peak food? Shortages loom as global production rates slow. Staples like wheat, chicken and rice are slowing in growth – with dire consequences. Independent

The world has entered an era of “peak food” production with an array of staples from corn and rice to wheat and chicken slowing in growth – with potentially disastrous consequences for feeding the planet.

Peak chicken was in 2006, while milk and wheat both peaked in 2004 and rice peaked way back in 1988, according to new research from Yale University, Michigan State University and the Helmholtz Centre for Environmental Research in Germany.

What makes the report particularly alarming is that so many crucial sources of food have peaked in a relatively short period of history, the researchers said.

“Mankind needs to accept that renewable raw materials are reaching their yield limits worldwide,” said Jianguo “Jack” Liu, of Michigan State University.

“Just nine or 10 plants species feed the world. But we found there’s a peak for all these resources. Even renewable resources won’t last forever,” said Ralf Seppelt, of the Helmholtz Centre.

This synchronisation of peak years is all the more worrying because it suggests the whole food system is becoming overwhelmed, making it extremely difficult to resurrect the fortunes of any one foodstuff, let alone all of them, the report suggested.

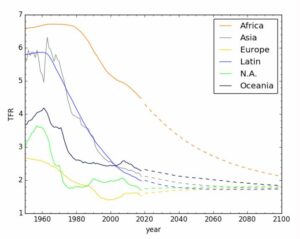

The simultaneous peaking of the world’s basic foodstuffs is largely down to the competing demands of a mushrooming population, which is putting ever-greater strain on the land for housing, agriculture, business and infrastructure. At the same time, producing more of any one staple requires the use of extra land and water, which increases their scarcity and makes it harder to increase food production in the future.

Finally, increases in production tend to push up pollution, which exacerbates shortages of resources and slows the growth in output.

The simultaneous peaking of crops and livestock comes against a backdrop of a growing population, which is expected to reach nine billion by 2050, requiring the world to produce twice as much food by then as it does now, according to a separate study by the California Academy of Sciences. The problems caused by the growing population have been compounded by the growth of wealthy middle-class populations in countries such as China and India which are demanding a meatier diet. This is problematic because meat and dairy use up a lot more resources than if a comparable level of nutrition were provided by crops, grown direct for human consumption.

Among the basic foodstuffs examined, only the relatively undeveloped farmed fish – or aquaculture – industry has yet to reach peak production.

References

Deepak, K. R., et al. 2019. Climate change has likely already affected global food production. PLOS ONE.

FI (2015) What does “Peak Food” mean and is it a problem? Foodindustry.com

Seppelt, R., et al. 2014. Synchronized peak-rate years of global resources use. Ecology and Society 19.

Source: (

Source: (

U.N.Total fertility rate projections

U.N.Total fertility rate projections