Preface. We must electrify trucks since fuel from oil, coal, and natural gas is finite, and biomass doesn’t scale up. Without transportation, electricity contraptions like wind turbines, solar facilities, and nuclear power plants can’t be built. A wind turbine, for example, needs trucks from start to finish. Each has 8,000 parts made around the world. Then there are the cement, bulldozers, cranes, and other trucks that prepare the wind turbine site, and the trucks that deliver the wind turbine to its destination. Trucks were also used to mine and crush the ores windmills are made of, the high heat to make the cement and steel in the turbine, to build and maintain the roads the 8,000 parts traveled on, and the transmission that connects wind turbines to the grid.

Since without trucks, civilization shuts down within a week, there is no higher priority than keeping trucks running. But there are many obstacles to building a catenary system for trucks, which I will explain in this article.

I mainly focus on the Port of Los Angeles and San Pedro project to run drayage trucks from the ports to inland warehouses because they’ve done by far the most research on what it would take to run trucks on a catenary system.

Alice Friedemann www.energyskeptic.com Author of Life After Fossil Fuels: A Reality Check on Alternative Energy; When Trucks Stop Running: Energy and the Future of Transportation”, Barriers to Making Algal Biofuels, & “Crunch! Whole Grain Artisan Chips and Crackers”. Women in ecology Podcasts: WGBH, Jore, Planet: Critical, Crazy Town, Collapse Chronicles, Derrick Jensen, Practical Prepping, Kunstler 253 &278, Peak Prosperity, Index of best energyskeptic posts

***

But first, what is a catenary truck?

A catenary truck is a lot like a trolley bus. Both run on electric motors powered by overhead lines, the catenary system. Catenary trucks differ from trolleys though, because they need a second propulsion method after they get off the wires to deliver their products and get back to the overhead lines. Trucks also need to get off the lines to pass one another, operate when the electricity is down, and get around trucks that have broken down.

The need for a dual mode doubles, or even triples the cost of a catenary truck. On top of that, it costs millions of dollars per mile to install a catenary system, plus add more electricity generation, substations, and transmission. Catenary is expensive to maintain as well, and if you’ve ever ridden MUNI trolley buses in San Francisco, you’ve probably been on a bus where the trolley poles detached from the catenary at a bad switch or too sharp a turn and waited many minutes for the driver to reattach the poles.

Even if we could build catenary systems for long-haul and delivery trucks, what about all the off-road trucks? Can you imagine stringing overhead wires across millions of acres of farmland, construction sites, sand and gravel mining, logging, and along transmission wires to maintain them? Rural areas were the last to be electrified, and would need a great deal more power plants, substations, and other electrical infrastructure to power these off-road uses.

If this were attempted, the rough terrain is likely to cause dewirement when the catenary poles detach from the wire at a pothole or bad switch.

Of course, there are mines that have electric mining trucks that run on extremely smooth roads, but the vast majority of the world’s ores are too far from the electric grid to electrify them. Mining sites that use catenary trucks typically have an onsite power plant generating electricity because the cost of diesel is so high in that region. These trucks only use electricity on the uphill or downhill part of the road, and operate on diesel when the road is level. Diesel operation is also required because catenary is very expensive and can’t be placed everywhere at the mining site. Batteries are not used because they drain quickly, are heavy and expensive, and take a long time to charge (Python 2010).

So far the Ports of Los Angeles and San Pedro have done the most research on what it would take to make a catenary system possible for drayage trucks between the ports and inland distribution warehouses. Their interest in doing this is solely for air quality, energy efficiency and conserving oil aren’t considerations.

The ports don’t know if a catenary system for trucks is possible. According to Calstart (2013), this is a new situation. San Francisco has one of the largest catenary transit systems in the world, with 300 trolleybuses and 150 light rail cars. But on average they’re running 10 minutes apart. In contrast, the I-710 drayage truck corridor has over 10,000 trucks that can weigh twice as much running seconds or less apart. Estimating the power needed, and whether the power can be distributed to all of them is unknown.

Although Sweden, Germany, and the USA are all in the process of building demonstration catenary systems about a mile long and a few dual-mode trucks to run on them, most of them with non-renewable diesel or natural gas backup), these experiments are more concerned with whether trucks can connect and disconnect from the catenary at high speed and won’t answer the question of whether thousands of trucks can run seconds apart, and how much power it would take to do so.

And consider the scale. There are 16,349 catenary trucks expected to be running in 2020 (SCAG 2013), that’s orders of magnitude more than San Francisco’s MUNI catenary vehicles: 311 trolley buses and 151 light-rail cars. And heavy-duty trucks are heavy. They can weigh twice as much as a trolley bus and require more power to move.

In California, four demonstration trucks (and a similar number in Sweden) are planned for the mile-long catenary being built, with the following second modes after leaving the wire: a battery that can go for 10 miles (ARB SEP 2014), a truck that runs on diesel, and two that run on compressed natural gas (Hsu 2016).

It will be hard to build dual-mode trucks that can even come close to matching the performance of today’s diesel drayage trucks, which go 400 miles between refueling, last 604,000 miles, haul up to 44,000 pounds, operate at temperatures from 23 to 113 degrees F, go up 6% grades, and travel 10 to 14 hours a day. Diesel drayage trucks are also far less expensive — a used one can cost as little as $3,000, a new one $104,360 (Calstart 2013). A Battery Electric truck (BEV) truck costs $307,890 (ICCT 2013), a hydrogen fuel cell truck $1.3 million (ARB 2015), and a natural gas catenary truck $282,000 (GNA 2012).

Why use dual-mode catenary trucks rather than a 100% battery electric truck?

Batteries / battery packs weigh too much. Even if 5 to 10 times as much battery energy density (Wh/kg) were achieved and other technical issues solved, batteries would still weigh too much: 2 to 4 tonnes (4400 to 8800 pounds) in a 40 tonne truck. Today’s batteries are 5 to 10 times heavier than 2 to 4 tonnes (ICCT 2013).

With today’s technology, driving a semi-truck 500 miles would require a 23-ton (46,000 pound) lithium-ion battery, half the weight of the truck itself (Coren 2016).

This is why the Ports of Los Angeles and Long Beach ruled out battery-electric (BEV) trucks, which need a 7,700 pound battery, since the weight cuts too much into the payload. Also, the battery only lasts for 100, half the 200 minimum-miles required. BEVs are also out of service too often, and take too long to recharge — 4 hours every 120 miles (Calstart 2013b).

Another disadvantage of 100% battery operated BEV trucks is the need for twice as many of them (32,968) as dual-mode catenary/battery (C/B) trucks (16,349), since the battery can be continually charged from the overhead wires, while an all-battery truck will need to be charged every few hours for a few hours. Nor would battery swapping solve the BEV problem, since it would be too expensive to carry multiple batteries for each truck (SCAG 2013) at all of the very expensive battery-swapping stations (Berman 2011).

Other alternatives: Compressed Natural Gas (CNG), hydrogen fuel cell, fixed-guideways

CNG trucks. Aside from the fact that natural gas is finite and not a solution, CNG tanks are heavy as well, would require a new fuel distribution system, with each station costing $1 million or more. CNG would add over 5,000 pounds to the truck weight: 300 gallons of diesel = 1,140 gallons of CNG at 1.81 lbs/gallon (2072 lbs), CNG tank 1,800 lbs, 1,300 pounds for the racks and protective plates (Schneider 2014).

Hydrogen fuel cell trucks are too heavy. Even if this technology were commercial for trucks, each one would need a a $2 million hydrogen fuel tank to go the distance (Coren 2016). The cost of building a hydrogen distribution system is far too high since very expensive special metals and gaskets are needed to keep the hydrogen from embrittling the metal and escaping, so the hydrogen would have to be made on-site. Each station would cost $1 million or more.

Fixed-guideway system. This zero-emission solution was rejected because over 20 years it would cost 14 times more than a dual-mode catenary system (GNA 2012 page 18).

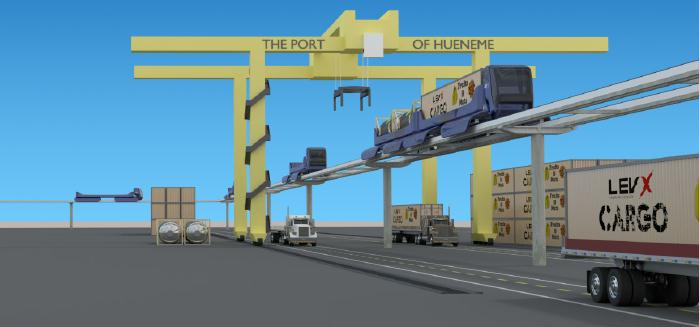

Source: Klinski, J. 2015. LEVX intermodal freight transport system. Port of Hueneme. California sustainable freight action plan. Magna Force, Inc.

How much power would catenary trucks on 24 miles of wires along I-710 need?

From .29% (ICF 2014) to 1% of all the electricity generated in California in a year on 24 miles of road, assuming:

- 16,349 hybrid catenary trucks I-710 in 2020 (SCAG 2013)

- 3 round-trips per day per truck (Calstart 2013. On good days 4 to 5 trips are made)

- 48 miles per round trip (24 * 2 miles of catenary wires on I-710)

- 313 days of drayage deliveries (ports are closed on Sundays)

- 3.5 kWh/mile (2.21 kWh/kilometer) due to the inefficiency of the dynamic loading on catenary wires, with a 10% efficiency loss assumed (ICCT 2013).

- California produces 250,561 GWh of power a year (ICF 2014)

Calculation:

- 2579 GWh needed by all catenary trucks per year = 16,349 trucks * 3 round-trips * 48 miles per trip round-trip * 313 days per year * 3.5 kWh/mile (3,438,783,264 kWh)

- 1% of all generated California electricity used per year = 2579 GWh / 250,561 GWh per year California

- 100% / 1% * 24 miles = 2,400 miles of roads for drayage trucks would use all of California’s electricity, 32,000 drayage trucks is 1,200 miles

- .16 GWh per truck per year = 2579 GWh per year / 16,349 trucks

ICF 2014 estimates .29% of annual power in their Aggressive Adoption by 2030 scenario.

- .29% of all generated California electrity used per year = 722 GWh all trucks/year (table 13) / 250,561 GWh per year California

- Consume 3 kWh/mile (page 87). Using 3 kWh lowers my calculation to 2211 GWh/year, .88% of California electricity, still 3 times more than .29%

- 36,100 trucks = 722/.02 .02 GWh/year/truck (table 33), all trucks 722 GWh/year.

- 241,000,000 total miles all trucks a year (Table 12). Therefore, every day all trucks drive 769,968 miles collectively (241,000,000 / 313 working days).

- 100% / .29% * 24 miles = 8,275 miles of roads would use all of California’s electricity

- Just 21 miles/day on catenary = 769,968 miles a day all trucks / 36,100 trucks. If just 21 catenary miles, the other mode must go 180 miles a day if the 200-mile a day specifications are met. So I don’t know how they came up with the .29% estimate. I think it is higher than that.

Overall on-road California catenary trucks might use 35% of electricity

Overall, the 952,000 medium and heavy-duty trucks registered in the state (CEC 2015) went 24,800,000,000 miles 2008 in California * 3.5 kWh = 86,800 Gwh/250,561 GWh. Or perhaps less power, if only the most important trucks were electrified, and the medium trucks might need less power, say 2.5 kWh, so perhaps half as much.

All of them would need to be modified to connect to the catenary and have electric motors. Since oil is finite, eventually all of them would have to be replaced with batteries or hydrogen systems, which may never exist due to the laws of physics. Plus additional new dual-mode trucks would need to be built and placed on California’s border to transfer cargo arriving in out-of-state trucks.

Even when oil shortages begin, the fact that off-road trucks aren’t electrified won’t matter, because tractors, harvesters, and other diesel farm equipment will have the highest priority for oil. But then what?

Unless a great deal more electricity generation is built for this new purpose, all other electricity users will need to cut back.

If all vehicles run on overhead wires,that’s 2.5 times more power than generated in California and 3 times more than United States generation

If all vehicles ran on overhead wires in California, that’s 322,849,000,000 miles in 2010 times 2 kwh (not 3.5, since lighter-weight vehicles will need less electricity than heavy-duty trucks) = 646,000 GWh, which is 2.5 times California’s 250,561 GWh generation. Of course, if the sacred economic myth that there are no limits to growth is true, we’ll need more power than that.

In 2014 in the USA in 2014, total vehicles traveled was 6,063,699,556,220 miles, so all vehicles would use 12,127 TWh of United States electricity generation, about 3 times more than the 4,052 Twh generated in 2014.

Conclusion

Catenary electric trucks are proposed for zero-emissions, not energy conservation or efficiency. The Ports of Los Angeles and Long Beach are trying to reduce the pollution of diesel drayage trucks hauling containers between the two ports and inland warehouses. Currently the I-710 has 10,000 drayage trucks making 3 to 5 round-trips a day. Analysts need to determine whether the energy to build and maintain a new catenary system and dual-mode trucks is greater than running more fuel-efficient trucks, especially if a 100% renewable electric grid is not possible.

Catenary is impossible: commercial level batteries aren’t energy-dense enough and far too heavy. The same goes for hydrogen fuel cells. And hydrogen is a net energy loser from start to finish, from splitting water, compression or liquefaction, storage, and distribution.

Catenary is too expensive. Catenary systems cost about $6 million per mile, so 175,000 miles of roads would cost $1,050,000,000,000,000 plus expensive operational and maintenance costs.

Catenary locks in a very expensive infrastructure on a road that may not be heavily used in the future.

The father in “Angela’s ashes” spent his earnings on booze rather than food for his children. Is a goal of zero-emissions, rather than energy efficiency, really the best way to spend our remaining energy?

Related Posts: There are many other barriers to building a battery electric car or truck. They use many finite platinum group elements, precious elements, and rare earth elements. Plus there are dozens of challenges to improving batteries that must be overcome but can’t because of the laws of physics and thermodynamics. Nor are trucks going to be running on hydrogen: The dumbest & most impossible renewable.

The electric grid will eventually fail without utility scale energy storage of at least a month of electricity to compensate for seasonal deficits (When Trucks Stop Running Chapter 17 The Electric Blues). Natural gas is the main energy storage now (and coal), and essential for balancing the sudden life and death of wind and solar power. But natural gas and coal are finite. Yes, hydropower can also balance wind and solar, but mostly in the 10 lucky states that have 80% of it for just part of the year, and the few places that can afford multi-million-dollar batteries (though only for an hour or so). The electric grid could crash from a weapon or solar flare electromagnetic pulse and be down for a year or more. Electric trucks are impossible. Without trucks, civilization fails. And it’s checkmate as well, because manufacturing uses over half of all fossil fuels, and depends on the high heat only fossils can provide to make cement, steel and other metals, glass, brick, ceramics, microchips and so on. Manufacturing can’t be run on electricity, hydrogen, or anything else, as explained in Chapter 9 of Life After Fossil Fuels. No transportation? No Manufacturing? Then no electricity generating contraptions like solar panels or wind turbines can be built. Checkmate.

References

ARB. September 2, 2014. Heavy-duty hybrid vehicles technology assessment. California environmental protection agency, Air Resources Board.

ARB. 2015. Technology assessment: Medium- and Heavy-duty fuel cell electric vehicles.

Berman, B. 2011. Plug-and-play batteries: Trying out a quick-swap station for E.V.’s. New York Times.

Calstart. 2013. I-710 project zero-emission truck commercialization study. Calstart for Los Angeles County Metropolitan Transportation Authority. 4.7.

CEC. October 2015. 2016-2017 Investment plan update for the alternative and renewable fuel and vehicle technology program. California Energy Commission. CEC-600-2015-014-SD

CEC. 2016. California Electrical Energy Generation in 2015. California energy commission.

Coren, M.J. June 23, 2016. Siemens says it can power unlimited-range electric trucks using a 150-year-old technology. QZ.

Edelstein. July 10, 2016. Road for electric trucks with trolley-like catenary opens in Sweden. greencarcongress.

GNA. March 8, 2012. Zero-emission catenary hybrid truck market study. Gladsteni, Neandross & Associates.

Hirsch, R. L., et al. 2005. Peaking of world oil production: impacts, mitigation, & risk management. Department of energy.

Hoffert, et al 2002 Advanced Technology Paths to Global Climate Stability: Energy for a Greenhouse Planet, Science. Vol 298.

Hsu, T. July 18, 2016. 100-Year-Old Street trolley technology could completely change trucking. trucks.com. CNG: Kenworth Trucks , BAE Systems and TransPower.

ICCT. July 2013. Zero emissions trucks. An overview of state-of-the-art technologies and their potential. International Council for Clean Transportation.

ICF. September 2014. California transportation electrification assessment. Phase 1: final report. ICF International.

Python. 2010. Trolley Assisted Mine Trucks. Python Group mining.

SCAG. February 2013. On the Move. Southern California delivers the goods. Final report. Southern California Association of Governments.

Schneider, D. February 10, 2014. The fuel alternatives: CNG & LNG part 1. wearethepractitioners.com

Smil, Vaclav. 2010. Energy Transitions: History, Requirements, Prospects. Praeger.

2 Responses to Just 16,000 catenary trucks (out of 5.6 million) would use 1% of California’s electricity generation