Torchinsky J (2021) Watching A Truck Hauling Wind Turbine Blades Kinda Hurts Your Brain. Jalopnik.com

Preface. There must be many high wind locations that wind turbine blades can’t be transported to, limiting how many could be built even with a trillion dollar budget. Clearly wind turbines aren’t renewable when you consider the vast amounts of material and energy required that have to be replaced all over again every 20 years (and just 15 if offshore). As you watch these two videos of wind turbine construction, think about the huge amount of energy and material (videos here and another great wind turbine construction video).

As you’ll see in post 59 Reasons why wind power can not replace fossil fuels, a 2 MW wind turbine weighs 1688 tons: 1300 tons concrete, 295 tons steel, 48 tons iron, 24 tons fiberglass, 4 tons copper, .4 tons neodymium, .065 tons dysprosium and more (Guezuraga 2012; USGS 2011).

For comparison, I found two statistics for what an average house weighs: from 72 to 104 tons. So each 2 MW wind turbine weighs as much as 23 homes. And that’s renewable? Their lifespan is only 20 years (Daviddson et al 2014). And Offshore wind turbines last just 15 years.

And 2 MW is puny. Imagine what these must weigh:

- The offshore 12 MW Haliade-X offshore wind turbine will stand 260 meters (850 feet) tall with 107-meter-long (350 foot) blades.

- the onshore Enercon E-126/7.5 MW wind turbine has a hub height of 135m (443 feet), a 127m (417 ft) diameter rotor, and provides a swept area of 12,668m² (3 square acres).

Alice Friedemann www.energyskeptic.com Author of Life After Fossil Fuels: A Reality Check on Alternative Energy; When Trucks Stop Running: Energy and the Future of Transportation”, Barriers to Making Algal Biofuels, & “Crunch! Whole Grain Artisan Chips and Crackers”. Women in ecology Podcasts: WGBH, Planet: Critical, Crazy Town, Collapse Chronicles, Derrick Jensen, Practical Prepping, Kunstler 253 &278, Peak Prosperity, Index of best energyskeptic posts

***

MidAmerican Energy Company – From the Ground Up: Building our energy future, one turbine at a time

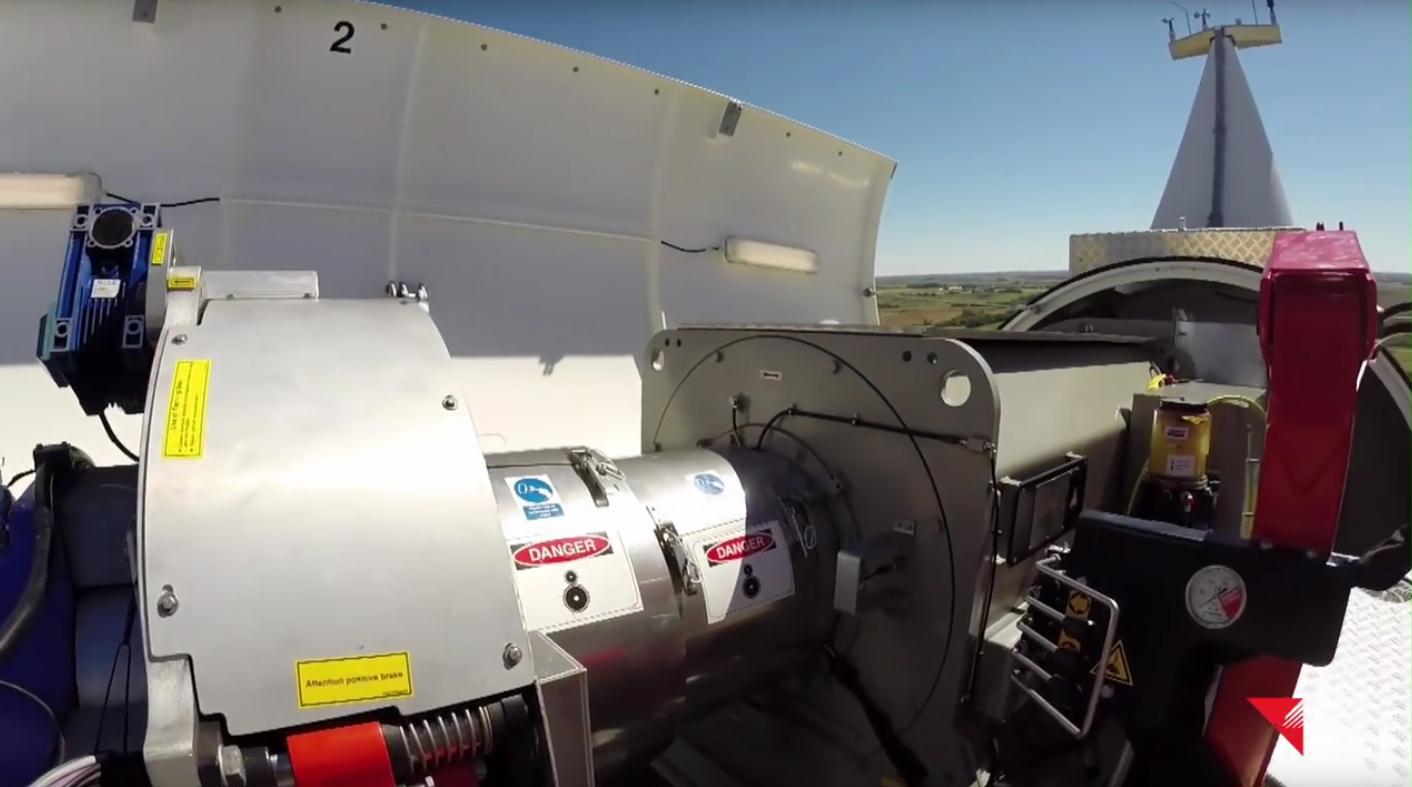

The pictures from the video capture how low the EROI of wind power must be when you can see the embodied fossil fuels used to build a wind turbine.

MidAmerican Energy announced they were about to build the tallest wind turbine in the US, a 2.3 MW 554 foot tall (with 173 foot blade extended) about the same as the Washington Monument. It will be 337 feet ground to hub, use 395 cubic yards of concrete, 63,400 pounds of reinforcing steel, and generate power when winds are 7 mph or higher, producing the most wind at 29 mph. Important figures such as cost, capacity, maintenance, and so on not (Remer).

MidAmerican Energy is owned by Warren Buffet, who has this to say about why he builds wind farms: “I will do anything that is basically covered by the law to reduce Berkshire’s tax rate,” Buffet told an audience in Omaha, Nebraska recently. “For example, on wind energy, we get a tax credit if we build a lot of wind farms. That’s the only reason to build them. They don’t make sense without the tax credit.” (Pfotenhauer).

Yet it doesn’t begin to capture all of the energy inputs to wind turbines. Notably, transmission is left out of the picture, and the natural gas plants to balance intermittent energy, the mining of the ores for iron and steel, or crushing of rocks to make cement/concrete, the fossil fuels in the tons of epoxy, and so on to make the 900 short tons of material (it is probably more like 1300 tons given other peer-reviewed publications on materials used in 2 MW turbines, not all of the materials used were included in this short video).

Most wind power will be forever stranded, because it’s too far from cities to run transmission lines to. If you look at the state level wind maps in the Wind Energy Resource Atlas of the United States List of Maps (RREDC) it appears as if cities have been placed as far from commercial wind power as possible. But no diabolical force is to blame. The distance is due to cities arising near good, flat farmland, yet the best wind is on the ridges of highlands. To get around this, wind turbines taller than the St. Louis arch at peak blade tip have been proposed for the Southeast and other areas without commercial wind (February 18, 2015. Mapping the Frontier of New Wind Power Potential. National Renewable Energy Lab.).

You’d need 32,850 wind turbines to replace the Cubic Mile of Oil consumed globally every year, and a grand total of 1,642,000 turbines to replace oil over the next 50 years, which may be conservative given that the wind isn’t blowing all the time so that triple or more would be needed on a national grid with massive energy storage batteries.

A wind turbine lifespan is only 20 years, so rinse and repeat!

Each windmill in this video:

- Takes 3 weeks to build from excavation to operation

- requires 40 to 100 geo-piers installed for stability, weight unknown

- Excavate 10 feet deep 100 feet wide

- Set 96,000 pounds of reinforcing steel rebar = 48 tons

- 53 concrete trucks pour foundations. If each truck can haul 8 cubic yards at 2538 lbs/yard * 53 = 1,076,112 pounds = 538 tons. In the second video, wind turbine farm from scratch, 30 to 240 cubic meters of concrete are poured (Delbert 2020). A cubic meter weighs 2,400 kg, so 72,000 kg / 152,738 lbs / 36 short tons to 576,000 kg / 1,269,863 pounds / 634 short tons

- Move 1,500 cubic yards of soil @ 2,200 lbs per cubic yard = 3.3 million pounds = 1,650 tons

- 3 blades : each 173 feet long and 27,000 pounds for 81,000 pounds = 40.5 tons

- 8 truckloads to deliver turbine components

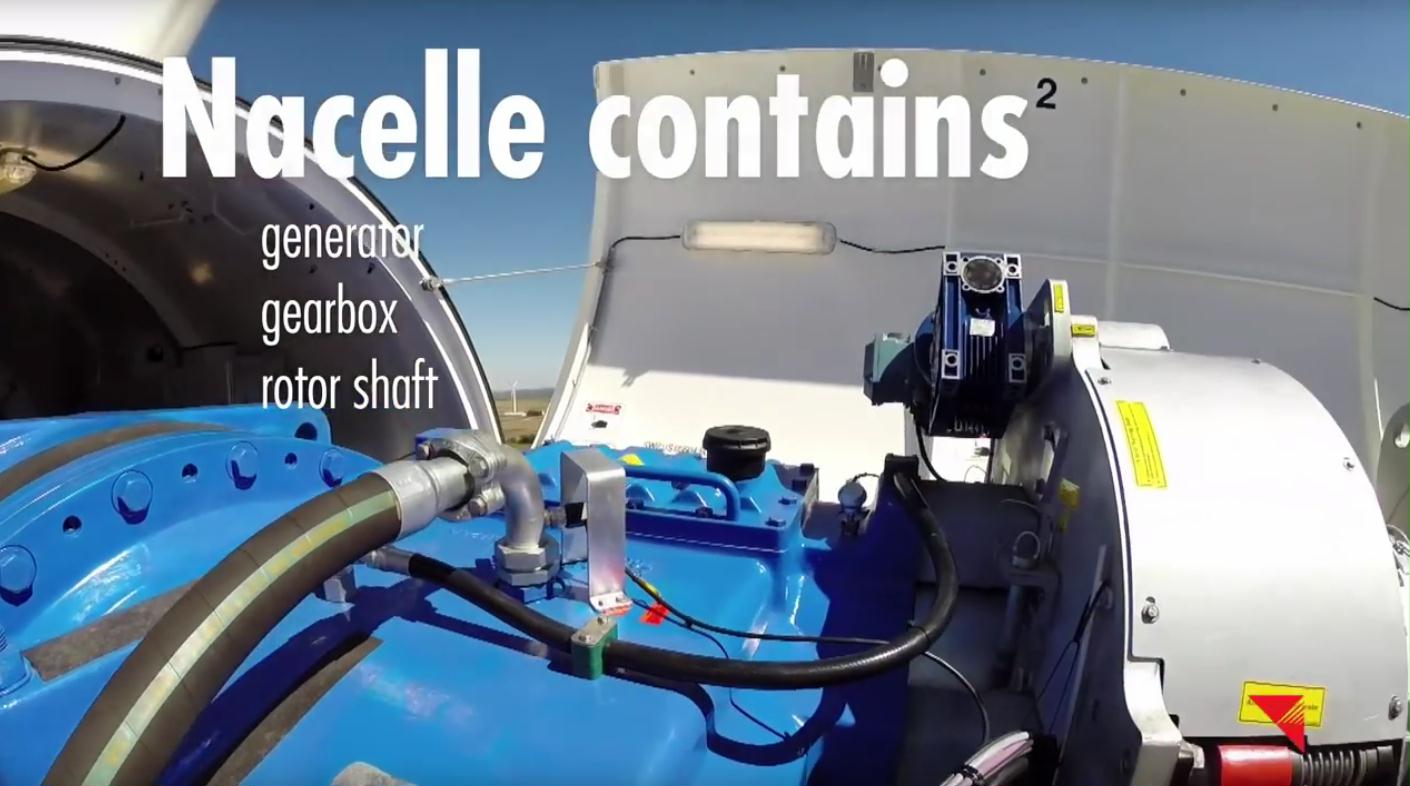

- Nacelle: weight 181,000 lbs = 90.5 tons with the generator, gearbox, and rotor shaft

- Hub: weight unknown

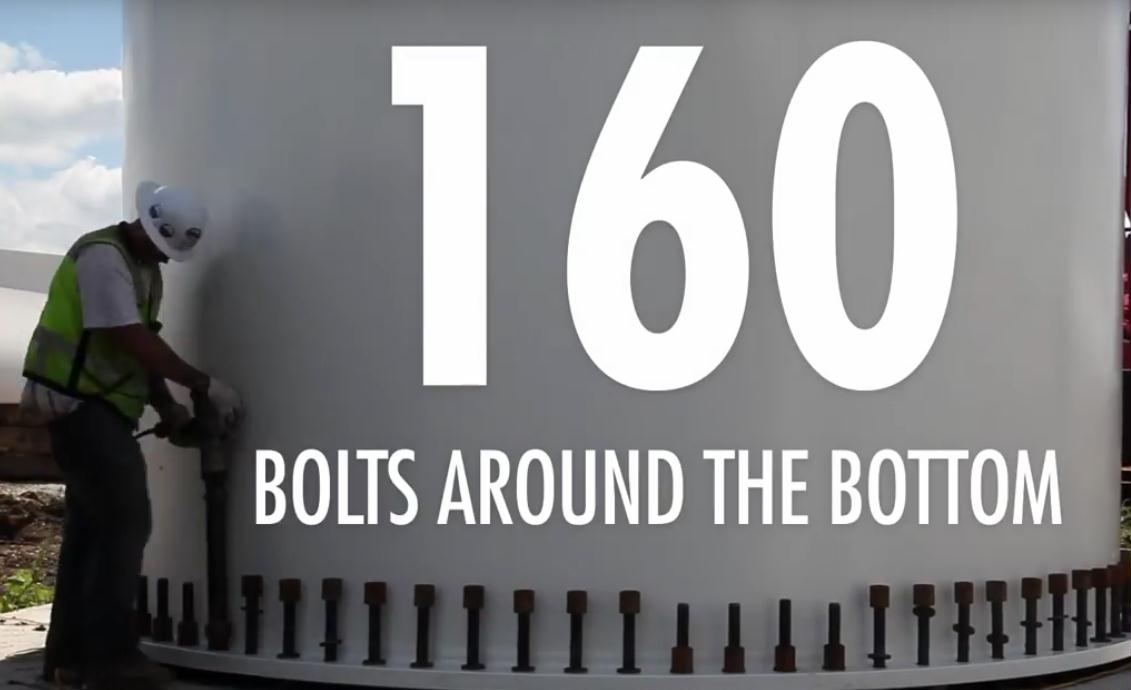

- Base tower height 53 feet 11 inches, weight 97,459 lbs = 48.7 tons

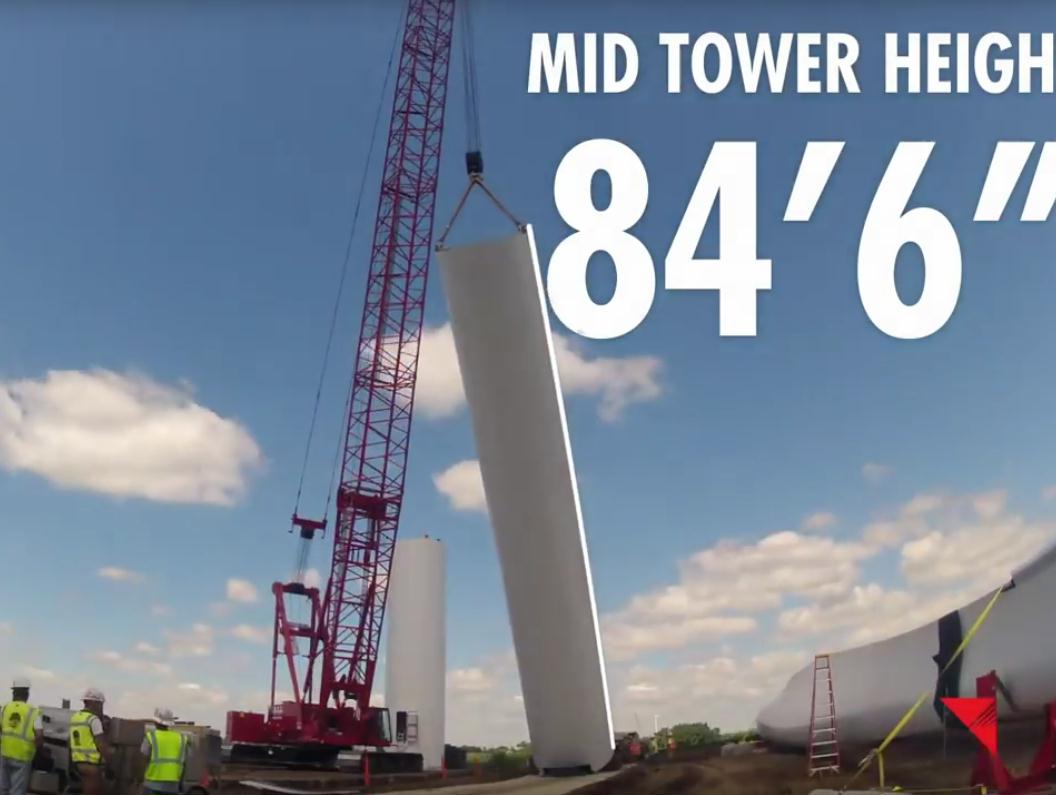

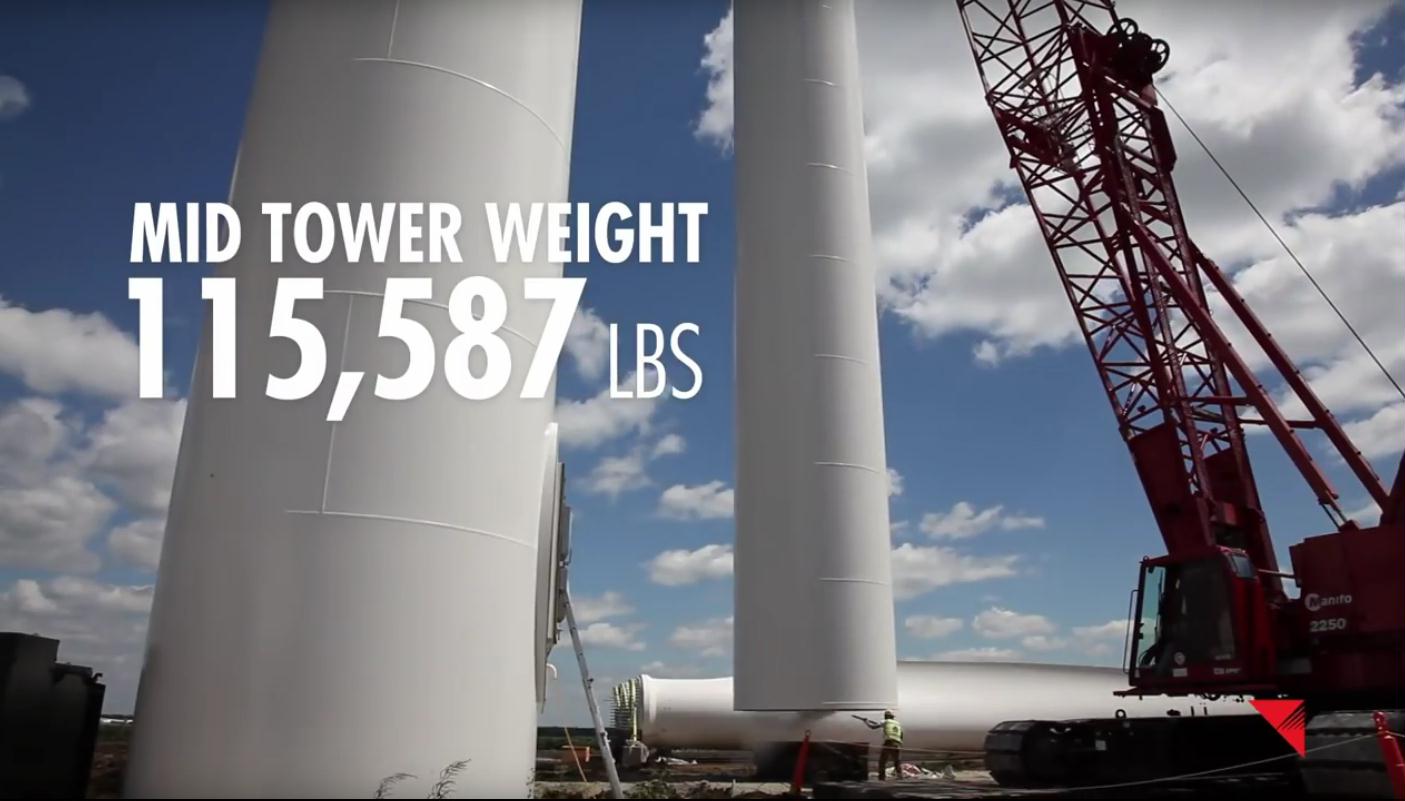

- Mid tower height 84 feet 6 inches, weight 115,587 lbs = 57.8 tons

- Top tower height 119 feet, weight 104,167 lbs = 52 tons

- Final tower height to blade tip when fully extended 442 feet

References

Pfotenhauer, N. May 12, 2014. Big Wind’s Bogus Subsidies. U.S. News & World Report

Remer, J. November 17, 2015. MidAmerican Energy’s New Iowa Wind Farm to Feature Tallest Onshore Turbine Ever in the US PowerEngineering.

Rosenbloom, E. 2006. A Problem With Wind Power. aweo.org

USGS. 2011. Wind Energy in the United States and Materials Required for the Land-Based Wind Turbine Industry From 2010 Through 2030. U.S. Geological Survey.

6 Responses to 1688 Tons of material to build just 1 windmill