Preface. Even a simple object like a pencil takes hundreds of actions and objects requiring fossil energy to do and make. Not electricity. This is on of many reasons why wind, solar, or other contraption that make electricity can’t replace fossil fuels. Electricity is only about 15% of overall energy use, with fossils providing the rest transportation, manufacturing, heating, and the half a million products made from fossils as feedstock as well as the energy source to make them.

Preface. Even a simple object like a pencil takes hundreds of actions and objects requiring fossil energy to do and make. Not electricity. This is on of many reasons why wind, solar, or other contraption that make electricity can’t replace fossil fuels. Electricity is only about 15% of overall energy use, with fossils providing the rest transportation, manufacturing, heating, and the half a million products made from fossils as feedstock as well as the energy source to make them.

Alice Friedemann www.energyskeptic.com Author of Life After Fossil Fuels: A Reality Check on Alternative Energy; When Trucks Stop Running: Energy and the Future of Transportation”, Barriers to Making Algal Biofuels, & “Crunch! Whole Grain Artisan Chips and Crackers”. Women in ecology Podcasts: WGBH, Jore, Planet: Critical, Crazy Town, Collapse Chronicles, Derrick Jensen, Practical Prepping, Kunstler 253 &278, Peak Prosperity, Index of best energyskeptic posts

***

Just as fish swim in water, we swim in oil. You can’t understand the predicament we’re in until you can see the oil that saturates every single aspect of our life.

What follows is a life cycle of a simple object, the pencil. I’ve cut back and reworded Leonard Read’s 1958 essay I Pencil, My Family Tree to show the fossil fuel energy inputs (OBJECTS made using energy, like the pencil, are in BOLD CAPITALS, ACTIONS are BOLD ITALICIZED).

“My family tree begins with … a Cedar tree from Oregon. Now contemplate the antecedents — all the people, numberless skills, and fabrication:

All the SAWS. TRUCKS, ROPE and OTHER GEAR to HARVEST and CART cedar logs to the RAILROAD siding. The MINING of ore, MAKING of STEEL, and its REFINEMENT into SAWS, AXES, and MOTORS.

The growing of HEMP, LUBRICATED with OIL, DIRT REMOVED, COMBED, COMPRESSED, SPUN into yard, and BRAIDED into ROPE.

BUILDING of LOGGING CAMPS (BEDS, MESS HALLS). SHOP for, DELIVER, and COOK FOOD to feed the working men. Not to mention the untold thousands of persons who had a hand in every cup of COFFEE the loggers drank!

The LOGS are SHIPPED to a MILL in California. Can you imagine how many people were needed to MAKE FLAT CARS and RAILS and RAILROAD ENGINES?

At the mill, cedar logs are CUT into small, pencil-length slats less than a quarter inch thick, KILN-DRIED, TINTED, WAXED. and KILN-DRIED again. Think of all effort and skills to make the TINT and the KILNS, SUPPLY the HEAT, LIGHT, and POWER, the BELTS, MOTORS, and all the OTHER THINGS a MILL requires? Plus the SWEEPERS and the MEN who POURED the CONCRETE for the DAM of a Pacific Gas & Electric Company HYDRO-ELECTRIC PLANT which supplies the mill’s POWER!

Don’t overlook the WORKERS and OIL BURNED by the RAILROAD LOCOMOTIVE to TRANSPORT SIXTY TRAIN-CARS of SLATS ACROSS the nation.

Once in the PENCIL FACTORY—worth millions of dollars in MACHINERY and BUILDING—each slat has 8 GROOVES CUT into them by a GROOVE-CUTTING MACHINE, after which the LEAD-LAYING MACHINE PLACES a piece of LEAD in every other slat, APPLIES GLUE and PLACES another SLAT on top–—a lead sandwich. Seven brothers and I are mechanically CARVED from this “wood-clinched” sandwich.

My “lead” itself—it contains no lead at all—is complex. The GRAPHITE is MINED in Sri Lanka. Consider these MINERS and those who MAKE their many TOOLS and the makers of the PAPER SACKS in which the graphite is SHIPPED and those who make the STRING that ties the sacks and the MEN who LIFT them aboard SHIPS and the MEN who MAKE the SHIPS. Even the LIGHTHOUSE KEEPERS along the way assisted in my birth—and the HARBOR PILOTS.

The graphite is mixed with CLAY FROM Mississippi in which AMMONIUM HYDROXIDE is used in the REFINING process. Then WETTING AGENTS and animal fats are CHEMICALLY REACTED with sulfuric acid. After PASSING THROUGH NUMEROUS MACHINES, the mixture finally appears as endless extrusions—as from a sausage grinder-cut to size, dried, and baked for several hours at 1,850 DEGREES FAHRENHEIT. To increase their strength and smoothness the leads are then TREATED with a hot mixture which includes CANDELILLA WAX from Mexico, PARAFFIN WAX, and HYDROGENATED NATURAL FATS.

My cedar RECEIVES 6 coats of LACQUER. Do you know all the ingredients of lacquer? Who would think that the GROWERS of CASTOR BEANS and the REFINERS of CASTOR OIL are a part of it? They are. Why, even the processes by which the lacquer is made a beautiful yellow involve the skills of more persons than one can enumerate!

Observe the LABELING, a film FORMED by APPLYING HEAT to CARBON BLACK mixed with RESINS. How do you make resins and what is carbon black?

My bit of metal—the ferrule—is BRASS. Think of all the PERSONS who MINE ZINC and COPPER and those who have the skills to MAKE shiny SHEET BRASS from these products of nature. Those black rings on my ferrule are black NICKEL. What is black nickel and how is it applied? The complete story would take pages to explain.

Then there’s my crowning glory, the ERASER, a rubber-like product made by reacting RAPE-SEED OIL from Indonesia with SULFUR CHLORIDE, and numerous VULCANIZING and ACCELERATING AGENTS. The PUMICE comes from Italy; and the pigment which gives “the plug” its color is CADMIUM SULFIDE.

Does anyone wish to challenge my earlier assertion that no single person on the face of this earth knows how to make me?

Actually, millions of human beings have had a hand in my creation, no one of whom even knows more than a very few of the others. Now, you may say that I go too far in relating the picker of a coffee berry in far off Brazil and food growers elsewhere to my creation; that this is an extreme position. I shall stand by my claim. There isn’t a single person in all these millions, including the president of the pencil company, who contributes more than a tiny, infinitesimal bit of know-how. From the standpoint of know-how the only difference between the miner of graphite in Sri Lanka and the logger in Oregon is in the type of know-how. Neither the miner nor the logger can be dispensed with, any more than can the chemist at the factory or the worker in the oil field—paraffin being a by-product of petroleum.

I, Pencil, am a complex combination of miracles: a tree, zinc, copper, graphite, and so on.”

Energy use in Agriculture (USDA)

It is estimated that 10 kilocalories of fossil fuels are used to produce just 1 kilocalorie of food. Not surprisingly, food-related energy use in the U.S. is quite large, growing from 14.4% of energy used in 2002 to 15.7% in 2007.

Energy is used throughout the U.S. food supply chain, from the manufacture and application of agricultural inputs, such as fertilizers and irrigation, through crop and livestock production, processing, and packaging; distribution services, such as shipping and cold storage; the running of refrigeration, preparation, and disposal equipment in food retailing and food service establishments; and in home kitchens. Dependence on energy throughout the food chain raises concerns about the impact of high or volatile energy prices on the price of food, as well as about domestic food security and the Nation’s reliance on imported energy.

Energy plays a large role in the life cycle of a food product. Consider energy’s contribution to a hypothetical purchase of a fresh-cut non-organic salad mix by a consumer living on the East Coast of the United States. After having read “I, Pencil” it is obvious that this description leaves out a great deal of actions and object energy embedded within the life cycle.

The farms’ fields are seeded months earlier with a precision seed planter operating as an attachment to a gasoline-powered farm tractor.

Fresh vegetable farms in California harvest the produce to be used in the salad mix a few weeks prior to its purchase.

Between planting and harvest, a diesel-powered broadcast spreader applies nitrogen-based fertilizers, pesticides, and herbicides, all manufactured using differing amounts of natural gas and electricity and shipped in diesel-powered trucks to a nearby farm supply wholesaler.

Local farmers drive to the wholesaler to purchase farm supplies.

The farms use electric-powered irrigation equipment throughout much of the growing period.

At harvest, field workers pack harvested vegetables in boxes produced at a paper mill and load them in trucks for shipment to a regional processing plant, where specialized machinery cleans, cuts, mixes, and packages the salad mixes.

Utility services at the paper mill, plastic packaging manufacturers, and salad mix plants use energy to produce the boxes used at harvest and the packaging used at the processing plant, and for processing and packaging the fresh produce. The packaged salad mix is shipped in refrigerated containers by a combination of rail and truck to an East Coast grocery store, where it is placed in market displays under constant refrigeration. To purchase this packaged salad mix, a consumer likely travels by car or public transportation to a nearby grocery store. For those traveling by car, a portion of the consumer’s automobile operational costs, and his or her associated energy-use requirements, help facilitate this food-related travel.

At home, the consumer refrigerates the salad mix for a time before eating it. Food-related household operations include energy use for storage, preparation, cleanup, and food-related travel, plus purchases of appliances, dishware, flatware, cookware, and tableware, as well as a small percentage of certain auto expenses to cover food-related travel.

Subsequently, dishes and utensils used to eat the salad may be placed in a dishwasher for cleaning and reuse—adding to the electricity use of the consumer’s household. Leftover salad may be partly grinded in a garbage disposal and washed away to a wastewater treatment facility, or disposed, collected, and hauled to a landfill. The consumer in the example purchased one of many units of this specific salad mix product sold each day in supermarkets nationwide, and this mixed salad product is one item among 45,000 distinct items with unique energy use requirements available in a typical U.S. supermarket.

Aside from the roughly constant 140,000 retail food and beverage stores operating in 2002 and 2007, there were also over 537,000 food and beverage service establishments in the United States in 2007, a 12-percent increase from 2002 (BLS, Quarterly Census of Employment and Wages). Each establishment purchases, stores, prepares, cleans, and disposes of food items. Other establishments, such as movie theaters, sports arenas, and hospitals, also perform some of these food-related services. 2 This salad mix example illustrates but is not a comprehensive accounting of all energy services related to producing, distributing, serving, and disposing of this product.

Life Cycle Assessment (LCA) and Energy Returned on Energy Invested (EROEI)

When it comes to replacing fossil fuels with another kind of energy, you want to be sure you aren’t merely building a Rube Goldberg contraption that churns out less power over its lifetime than the fossil fuel energy used to make the device.

There are decades-old scientific methods that try do do this. The best-known is the Life Cycle Assessment (LCA), which calculates the monetary costs and helps businesses shave costs.

When it comes to evaluating a device that produces energy, a better measurement is the Energy Returned on Energy Invested (EROEI, EROI), which subtracts the fossil fuel energy used in every step and component from how much energy is output over the lifetime of the contraption.

At the start of the fossil fuel age, each barrel of oil discovered could be used to find 100 more, a huge EROI. This enormous bounty of energy was used to build our fabulous civilization. Railroads finally ended famines, clean drinking water and sewage infrastructure raised the average lifespan from 40 to 80 years (Garrett), and oil made possible a million other things – cars, airplanes, movies, electronic goods, 100% comfort 100% of the time, just push a button to heat, air-condition, or cook.

Clearly a negative or break-even EROEI is a big problem. for example, if the fossil fuel energy needed to make ethanol is greater than or equal to the energy in the ethanol produced, then there is no extra energy left over to do anything. Many system ecologists have found the EROEI of ethanol to be negative (Pimentel), or so slightly positive that the tiny amount of excess energy produced wouldn’t be able to run society.

The problems with LCA and EROEI

No wonder complete studies with wide boundaries are seldom done. There are infinite regressions, since every object has its own LCA and EROEI. A Toyota car has about 30,000 parts. A windmill turbine has 8,000 components (AWEA). The supply chains (transportation fuel) for both involve thousands of companies and dozens of countries.

LCA & EROEI studies are bound to miss some steps. Reed’s pencil story left out the design, marketing, packaging, sales, distribution, and energy to fuel the supply chains between California, Oregon, Mississippi, Brazil, Sri Lanka, Indonesia, etc., and the final ride the pencil takes to the garbage dump.

Every step in a process subtracts energy from the ultimate energy delivered. Oil is concentrated sunshine that was brewed for free by Mother Nature. Building alternative energy resources requires dozens of steps, thousands of components, and vast amounts of energy in the supply chains of providing the minerals and pieces of equipment to make an alternative energy contraption.

Life Cycle Assessments (LCA) often use money rather than energy to calculate “costs”. Money is an artificial, abstract concept used to grease the wheels of commerce. Money varies in value over time for reasons of politics, financial cycles, and can’t be burned in combustion engines.

There are many different LCA tables to choose from. So scientists accuse each other of cherry-picking data or argue the data is out-of-date.

EROEI studies often leave out LCA monetary costs because they’re difficult to quantify as energy costs. For example, when the EROEI of a windmill farm is calculated, many costs are left out, such as insurance, administrative expenses, taxes, the cost of the land to rent or own, indirect labor (consultants, notary public, civil servants, legal costs, etc.), security and surveillance costs, the fairs, exhibitions, promotions, conferences attended by engineering staff, bonds, fees, and so on. Although Prieto and Hall managed to do so in their analysis of solar power in Spain (Part 1 & Part 2).

External (environmental damage) costs are rarely mentioned or considered. Making biofuels mines topsoil, depletes aquifers, creates immense eutrophication in the Gulf of Mexico and other waterways from fertilizer runoff, energy crops result in rainforests being cut down, and so on.

Weißbach, D., et al. also find these issues with LCA and EROI studies:

- Don’t take into account the need to buffer intermittent power. The EROI for wind is 16, but when you subtract the EROI of the energy storage to buffer wind power, the EROI overall is 4, well below the EMROI (Energy money returned on invested) requirement of 7 for an energy technology to be viable.

- Focus too much on CO2 emissions rather than energy

- Don’t take into account the much longer lifespans of fossil fuel power plants than Wind (20) or solar (30 – less, we don’t know yeet). CCGT NG plants can last 35 years, coal and gas turbines 50 years, refurbished nuclear power plants over 60 years, and hydropower can last 100 years or more.

- Assume some or all of the components are recycled and subtract the energy, even though new material is often cheaper than recycled often, and recycling takes energy

- Don’t take into account that getting raw materials keeps getting more energy expensive as concentrations in ores goes down from the best reserves being extracted first

- Don’t add in the energy costs to make devices safer and conform to environmental standards

- Wind EROI can be ‘gamed’ by using very low amounts of copper and other materials, or leaving them out entirely, using data from the best possible locations only (i.e. offshore or the best onshore locations.

- Ignore human labor costs

A report that chased down the energy in the infinite regressions of thousands of parts would take a lifetime and over a hundred thousand pages long. Therefore boundaries have to be set, which leads to never-ending fights between scientists. Just as tobacco industry funded scientific studies tended to find cigarettes did not cause cancer, energy industry-sponsored scientists tend to use very narrow boundaries and cherry-pick LCA data to come up with positive EROEI results, usually published in non-peer reviewed journals, which means the data and methods are often unavailable, making the results as trustworthy as science-fiction. Systems ecologists, the experts and inventors of EROEI methodology, use wider boundaries, include more steps and components, energy rather than financial data whenever possible, and publish in peer-reviewed journals. Peer-reviewed journals require a review by scientists in the same field, and the data and methods are available to everyone so that the results can be verified and reproduced.

On average, the EROEI results of university systems ecologists in peer-reviewed, high quality, respected journals are much lower than the energy industry sponsored scientists in non-peer-reviewed industry publications.

Alternative energy resources must be sustainable and renewable

What’s the point of making biofuels if unsustainable amounts of fresh water, topsoil, natural gas fertilizers, oil-based pesticides, and phosphorous are used?

Or windmills and solar PV, since they both depend on scarce, energy-intensive, and extremely damaging mining to get the rare (earth) and platinum metals required, leading to even more wars than we have now over oil to get rare minerals that exist only in foreign countries.

Nevertheless, EROEI studies are valuable because you can see some of the oiliness, even if it’s only a tiny fraction given how long it would take to include all 30,000 parts of a car or 8,000 parts of a windmill. The more studies you read, the more you can decide whether the boundaries were too narrow and which scientists wrote the most complete and fair study.

Civilization needs energy resources with an EROEI of at least 12

Charles A. S. Hall, who founded EROEI methodology, initially thought an EROEI of at least 3 was needed to keep civilization as we know it operating. After three decades of research, he recently co-authored a paper that makes the case that an EROEI of at least 12-14 is needed (Lambert).

Conclusion

An alternative energy resource built to replace oil had better have an EROEI over 12, or it’s just a Rube Goldberg contraption.

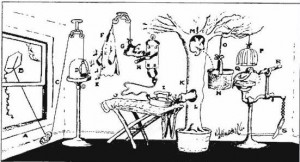

Rube Goldberg Pencil Sharpener

Open window (A) and fly kite (B). String (C) lifts small door (D) allowing moths (E) to escape and eat red flannel shirt (F). As weight of shirt becomes less, shoe (G) steps on switch (H) which heats electric iron (I) and burns hole in pants (J). Smoke (K) enters hole in tree (L), smoking out opossum (M) which jumps into basket (N), pulling rope (O) and lifting cage (P), allowing woodpecker (Q) to chew wood from pencil (R), exposing lead. Emergency knife (S) is always handy in case opossum or the woodpecker gets sick and can’t work.

References

AWEA. American Wind Energy Association. 2012. Anatomy of a Wind Turbine. There are over 8,000 components in each turbine assembly.

Farrell, et. al. Jan 27, 2006. Ethanol Can Contribute to Energy and Environmental Goals. Science Vol 311 506-508.

Garrett, L. 2003. Betrayal of Trust: The Collapse of Global Public Health. Oxford University Press.

Lambert, Jessica G., Hall Charles A. S. et al. 2014. Energy, EROI and quality of life. Energy Policy 64:153–167

Lambert, J. Hall, Charles, et al. Nov 2012. EROI of Global Energy Resources Preliminary Status and Trends. State University of New York, College of Environmental Science and Forestry.

Pimentel, D and Patzek, T. March 2005. Ethanol Production Using Corn, Switchgrass, and Wood; Biodiesel Production Using Soybean and Sunflower. Natural Resources Research, Vol. 14 #1.

USDA. March 2010. .Energy Use in the U.S. Food System United States Department of Agriculture.

Pingback: How Much are Non-Renewable Resources Really Worth? | The Soeller Panel