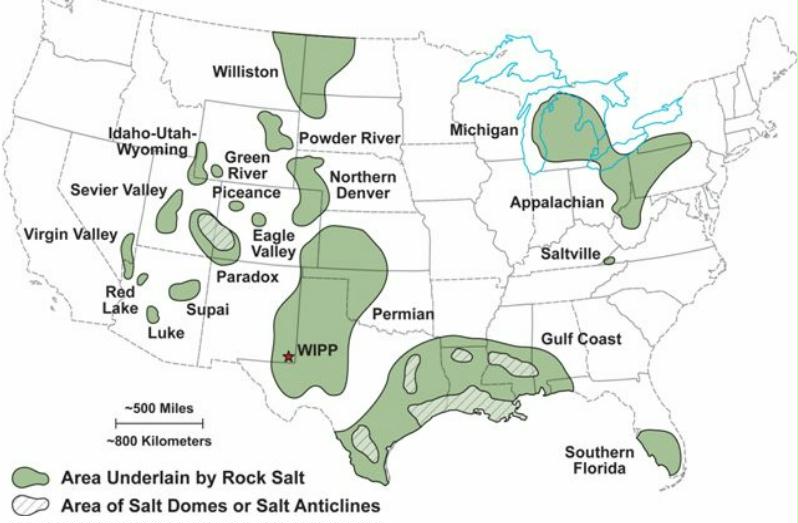

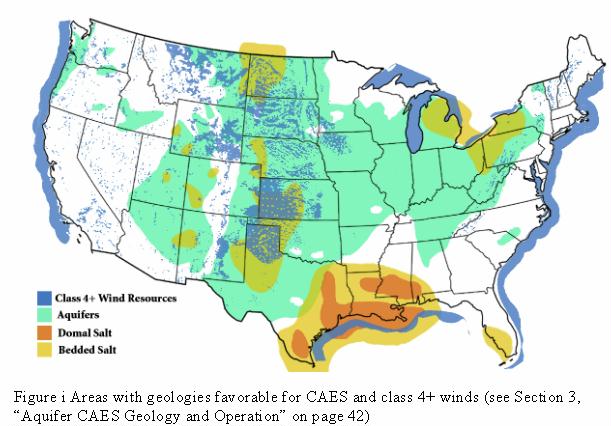

Preface. Besides pumped hydro storage (PHS), which provides 99% of energy storage today, CAES is the only other commercially proven energy storage technology that can provide large-scale (over 100 MW) energy storage. But there are just two CAES plants in the world because there are so few places to put them, as you can see in Figure 1 and Figure i.

CAES is the most sustainable energy storage with no environmental issues like what PHS poses, such as the flooding of land and the damming of rivers. And Barnhart (2013) rates the ESOI, or energy stored on energy invested, the best of all for CAES. Batteries need up to 100 times more energy to create than the energy they can store.

A more detailed and technical article on CAES with wonderful pictures can be found here: Kris De Decker. History and Future of the Compressed Air Economy.

Alice Friedemann www.energyskeptic.com author of “Life After Fossil Fuels – Back to Wood World”, 2021, Springer, “When Trucks Stop Running: Energy and the Future of Transportation”, 2015, Springer, Barriers to Making Algal Biofuels, and “Crunch! Whole Grain Artisan Chips and Crackers”. Podcasts: Collapse Chronicles, Derrick Jensen, Practical Prepping, KunstlerCast 253, KunstlerCast278, Peak Prosperity , XX2 report

***

How it works: Using off-peak electricity, compressed air is pumped into very large underground cavities at a depth of 1650–4250 feet (Hovorka 2009), and then drawn out to spin turbines at peak demand periods.

Uh-oh — it still needs fossil fuels. But a big drawback of CAES is that it still needs fossil fuels, since electric generators use natural gas to supplement the energy from the stored compressed air. Natural gas also provides the power to compress and pump the air underground, and when the compressed air is withdrawn, natural gas is used a second time to heat it and force it through expanders to power a generator. Current CAES facilities are essentially gas turbines that consume 40–60 % less gas than conventional turbines (SBC 2013).

Few locations: Domal salt formations are rare (orange in figure i below)

Locations are scarce because they must be airtight. There are only two CAES plants in the world: Alabama (110 MW) built in 1991 and in Germany in 1979, both of them in Domal Salt formations.

There are only two because domal salt formations are so rare and exist in only a few states in the U.S. as shown in figure i. These have one or more deep chambers within the salt dome that are airtight, so they can handle frequent charging and discharging, with pure, thick salt walls that self-heal with air moisture, preventing leaks. Bedded salt is not as ideal because it takes a huge amount of energy and water to carve salt chambers out. Domal salt is also superior because they are purer and thicker than bedded salt (Hovorka).

Areas with class 4+ wind and possible CAES locations. Succar. 2008. Compressed Air Energy Storage: Theory, Resources, And Applications For Wind Power. Princeton University.

Ideally a CAES facility would store renewable wind power, but the best wind locations are seldom near domal salt areas. Though there is a wind/CAES project being planned, an $8 billion dollar project in Utah. It would use the only known salt dome outside of Texas, Louisiana, or Alabama for a $1.5 billion dollar CAES to store electricity from a $4 billion wind farm in Wyoming to deliver power to Los Angeles over $2.6 billion of new transmission lines that run for 535 miles ($4.86 million/mile) (DATC 2014; Gruver 2014).

This is not exactly run of the mill geology. CAES has yet to be deployed in bedded salt, aquifers, or abandoned rock mines because these formations are less likely to be airtight, and hence able to charge and discharge frequently and to maintain constant pressure. Underground areas once but no longer used to store natural gas or oil would have to be free of blockages that could gum up the works. Water is another limiting factor. High volumes are needed to cool the compressed air before storing it.

CAES systems generally have twice as much up-ramping capability as down-ramping. Translation: They can produce electricity faster than they can store it (IEA 2011a).

They are inefficient

The CAES plants in operation in Germany and the US have an electric-to-electric efficiency of only 40–54%, respectively (Luo 2015). A conversion efficiency this low will require a doubling of wind and solar power to make up for the loss.

The Pacific Northwest National Laboratory calculated the cost of energy storage devices for balancing the grid if wind power reached 20 % of electric generation across the United States. The cost for CAES was the most expensive: 170.6 billion. Storage would fill spans ranging from milliseconds up to an hour. Not 2 hours, not a day, and not a week— that will cost you extra. In billions of dollars, the options examined included $54.03 NaS battery, $63.85 flywheel, $81.62 Li-ion battery, $116.61 redox flow battery, $125.06 demand response (car PHEV batteries), $130.24 pumped hydro storage (PHS), $135.48 combustion turbine (CT), and $170.62 compressed air energy storage (PNNL 2013).

Based on nine vendor estimates, to build CAES units able to store one day of U.S. electricity would cost from $912 billion to $1.48 trillion. That’s below ground. Above ground CAES would cost $3.8 trillion (DOE/EPRI 2013).

Locations must be near the electric grid: It’s far too expensive to add transmission from remote locations. It’s already too expensive to build them….

According to Alfred Cavallo, “The immense magnitude of stored energy required to transform the intermittent wind resource to a constantly available power supply is not widely appreciated. For example, a 200 MW wind/CAES plant would need a minimum storage capacity of 10,000 MWh, or 50 hours of full plant output (this assumes that the wind power density is constant throughout the year). If the wind was not constant, but seasonal, say mainly in the winter or spring, the energy storage for seasonal output would require a minimum of 40,000 MWh (200 hours of full power plant output). Clearly, only the most inexpensive of storage media, like air or water, could be used in such an application” (Cavallo 2007).

Since the wind is a seasonal resource, it would be ideal to be able to store weeks of wind energy, but that is impossibly expensive (Cavallo 1995).

CAES in aquifers has never been accomplished, and attempt to do so was abandoned after $8 million was spent in Iowa because testing found it would leak (see Haugen below). Aquifers are far more expensive than salt caverns, partly due to the high cost of conducting tests, such as seismic, drilling test wells, modeling the reservoir, and so on (Swensen, Hydrodynamics Group, Marchese). Aquifers may not be suitable for CAES– they have to have the right amount of porosity and permeability beneath an impermeable caprock with the right geometry (Succar). This makes it very expensive to find out.

Hard rock caverns, such as abandoned mines, are the least likely place to put CAES and this has never been attempted, leakage is too likely, and finding a mine at the exact right depth reduces the choices further.

Air has problems being stored that natural gas does not. Using underground storage that once had natural gas may not work, because “a CAES system used for arbitrage or backing wind power will likely switch between compression and generation at least once a day and perhaps several times a day. In contrast, most natural gas storage facilities are often only cycled once over the course of the year to meet the seasonal demand fluctuations for natural gas. Third, several oxidation processes might take place in the presence of oxygen from the air depending on the mineralogy of the formation. Also, introduction of air into the formation might promote propagation of aerobic bacteria that might pose a significant corrosion risk. Finally, additional corrosion mechanisms might be promoted due to the introduction of oxygen into the formation (Succar).

Haugen, D. 2012. Scrapped Iowa project leaves energy storage lessons. Midwest Energy News.

After spending $8 million on a CAES aquifer in Iowa, the project was halted when it was concluded that air didn’t flow fast enough through the aquifer for it to be effective as a compressed-air energy storage site.

Hydrodynamics Group. CAES in aquifers is problematic. Lack of geological data-poor. Reservoir properties.

Hydrodynamics has found that CAES in aquifer storage medium is problematic. We found that geological data for aquifer structures is typically very limited, resulting in costly exploration, field testing, and analysis development programs. Otrher challenges include constraint of air storage pressure around the hydrostatic pressure of the aquifer, limitations on well productivity, the potential for oxygen depletion, and the potential of water production with the air. We have found that the mitigation of the challenges of CAES development is dependent on the selection of an anticline structure at the proper depth, and the choice of highly permeable porous medium.

REFERENCES

Barnhart, CJ, et al. 2013. On the importance of reducing the energetic and material demands of electrical energy storage. Energy & Environmental Science.

Cavallo, A. et al. 1995. Cost effective seasonal storage of wind energy. Houston, TX, USA, pp. 119-125.

Cavallo, A. 2007. Controllable and affordable utility-scale electricity from intermittent wind resources and compressed air energy storage (CAES). Energy 32: 120-127.

DATC. 2014. $8-billion green energy initiative proposed for Los Angeles. Los Angeles: Duke

American Transmission Co.

Denholm. September 23, 2013. Energy Storage in the U.S. National Renewable Energy Laboratory. Slide 15.

DOE/EPRI. 2013. Electricity storage handbook in collaboration with NRECA. USA: Sandia

National Laboratories and Electric Power Research Institute.

Gruver, M. 2014. Renewable energy plan hinges on huge Utah caverns. New York: Associated Press.

Hovorka, S. 2009. Characterization of Bedded Salt for Storage Caverns: Case Study from the Midland Basin . Texas Bureau of Economic Geology.

Hydrodynamics Group. 2009. Norton compressed air energy storage. http://hydrodynamics-group.com/mbo/content/view/16/40

IEA. 2011. IEA harnessing variable renewables: a guide to the balancing challenge. Paris: International Energy Agency.

Luo X, et al. 2015. Overview of current development in electrical energy storage technologies and the application potential in power system operation. Applied Energy 137: 511-536.

Marchese, D. 2009. Transmission system benefits of CAES assets in a growing renewable generation market. Energy Storage Association Annual Meeting.

NREL. 2014. Renewable Electricity Futures Study. National Renewable Energy Laboratory.

PNNL. 2013. National assessment of energy storage for grid balancing and arbitrage: phase II, vol 2: cost and performance characterization. Washington, DC: Pacific Northwest National Laboratory.

SBC. 2013. Electricity storage. SBC Energy Institute.

Succar, S. et al. 2008. Compressed Air Energy Storage: Theory, Resources, and Applications for Wind Power. Princeton Environmental Institute.

Swensen, E. et al. 1994. Evaluation of Bene ts and Identi cation of Sites for a CAES Plant in New York State. Energy Storage and Power Consultants. EPRI Report TR-104268.