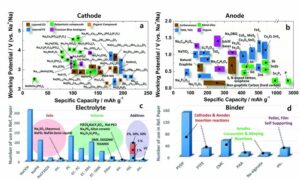

Recent research progress in sodium ion batteries: (a) cathode, (b) anode, (c) electrolyte and (d) binder. Source: Hwang J (2017) Sodium-ion batteries: present and future. Chem. Soc. Review 46: 3529-3614 DOI: 10.1039/C6CS00776G

Preface. If lithium were used for both EV and utility scale energy storage, reserves would not last long. But there’s a lot of sodium. A sodium battery is better than lithium as well because it is safer and keeps most of the charge when temperatures fall far below freezing.

But sodium batteries have an enormous disadvantage: they need to be bigger than lithium batteries to hold the same electrical charge. So this doesn’t solve the #1 energy crisis problem: Transportation. They’d be far too heavy to electrify long-haul trucks, tractors, locomotives, ships, and other heavy-duty vehicles that run on diesel.

Their best use would be large-scale electric grid energy storage. In fact, Sodium sulfur (NaS) batteries are the only kind of large-scale energy storage for which there are enough materials on earth (Barnhart 2013).

Although Barnhart may be wrong about the amounts of sulfur available. Sure, sulfur is the fifth most common element in the world, but deposits large enough to exploit are extremely rare, mostly near volcanoes. Most sulfur or sulfates are combined with copper, iron, lead, zinc, barium, calcium (aka gypsum), magnesium, and sodium.

Today 80% comes from oil and natural gas refining into pure elemental sulfur, safe and easy to transport, unlike sulfuric acid, and with the bonus of preventing sulfur dioxide emissions and acid rain. But there are scientists warning about 25 years of conventional oil left in the world at current rates of consumption. Others say more than that. But whatever the amount left, exponential growth from population and capitalism shortens consumption time.

To summarize how far utility energy storage is from being able to store just one day of U.S. electricity generation (11.12 TWh) — even NaS batteries can’t do it. Using data from the Department of Energy (DOE/EPRI 2013) I calculated the cost, size, and weight of NaS batteries capable of storing 24 hours of electricity generation.

The cost would be $40.77 trillion dollars, cover 923 square miles, and weigh a husky 450 million tons. With a lifespan of just 15 years.

Sodium Sulfur (NaS) Battery Cost Calculation:

- NaS Battery 100 MW. Total Plant Cost (TPC) $316,796,550. Energy

Capacity @ rated depth-of-discharge 86.4 MWh. Size: 200,000 square feet. - Weight: 7000,000 lbs, Battery replacement 15 years (DOE/EPRI p. 245).

- 128,700 NaS batteries needed for 1 day of storage = 11.12 TWh/0.0000864 TWh.

- $40.77 trillion dollars to replace the battery every 15 years = 128,700 NaS * $316,796,550 TPC.

- 923 square miles = 200,000 square feet * 128,700 NaS batteries.

- 450 million short tons = 7,000,000 lbs * 128,700 batteries/2000 lbs.

Using similar logic and data from DOE/EPRI, Li-ion batteries would cost $11.9 trillion dollars, take up 345 square miles, weigh 74 million tons, and a lifespan of 15 years. Lead–acid (advanced) would cost $8.3 trillion dollars, take up 217.5 square miles, and weigh 15.8 million tons. (See the chapter in my book “When Trucks stop running” for details).

This is crazy — it is hard to get the sodium these batteries require. Their cathodes use soda ash (Na₂CO₃). Over 90% comes from deep under Wyoming, USA, in a vast deposit formed 50 million years ago. This is cheaper than extracting NaCl from the ocean and converting it to sodium carbonate. But it can be done. China has very little soda ash, and the synthetic version they make at chemical plants is powered by coal, and has caused toxic water pollution.

Like all breathless battery breakthroughs, don’t hold your breath. Nobody knows how long sodium batteries can last outdoors, since they’re still at the laboratory stage, far from being commercial. Meanwhile, tick-tock, peak oil production may have happened in 2018.

References

Barnhart CJ et al (2013) On the importance of reducing the energetic and material demands of electrical energy storage. Energy Environ. Sci 6: 1083-1092

Bradsher K (2023) Why China Could Dominate the Next Big Advance in Batteries. New York Times https://www.nytimes.com/2023/04/12/business/china-sodium-batteries.html?searchResultPosition=1

DOE/EPRI. 2013. Electricity storage handbook in collaboration with NRECA. USA: Sandia National Laboratories and Electric Power Research Institute.

Alice Friedemann www.energyskeptic.com Author of Life After Fossil Fuels: A Reality Check on Alternative Energy; When Trucks Stop Running: Energy and the Future of Transportation”, Barriers to Making Algal Biofuels, & “Crunch! Whole Grain Artisan Chips and Crackers”. Women in ecology Podcasts: WGBH, Financial Sense, Jore, Planet: Critical, Crazy Town, Collapse Chronicles, Derrick Jensen, Practical Prepping, Kunstler 253 &278, Peak Prosperity, Index of best energyskeptic posts

***