Source: Russel Rhodes (2011) Explosive Lessons in Hydrogen Safety. https://appel.nasa.gov/2011/02/02/explosive-lessons-in-hydrogen-safety/

Preface. What is hopium? Irrational or unwarranted optimism. An addiction to false hopes. A metaphorical substance that causes people to believe in a false hope (H + opium). And Hopium makes fuel cell hydrogen cars! What could be more suitable for today’s post.

No container can contain hydrogen for long. Use it or lose it. Hydrogen is the Houdini of elements, the smallest of them all, and will boil off and escape no matter how many gaskets and valves there are on a container and at every pipeline junction.

On cars, this flaw may be the death knell of hydrogen for autos:

Liquefied hydrogen (LH2) automobiles face a major challenge: their extreme sensitivity of LH2 to heat transfer from the environment, resulting in rapid pressurization potentially leading to venting hydrogen if the maximum pressure is reached and the relief device opens. Avoiding vent losses requires enough driving to consume evaporated LH2 still in the tank before it boils off. In the real world this often doesn’t happen because personal vehicles are parked for days or even weeks before driven again. Even the best multilayer insulation has a hard time reducing heat transfer to the necessary level due to the relatively small capacity (~10 kg H2) of automotive LH2 tanks, leading to large surface area to volume ratios. These and other challenges may lead to the demise of LH2 automobiles (Ahulwalia 2024)

The challenge of avoiding large LH2 losses, along with the maturity of composite vessels for high pressure gaseous hydrogen (GH2) [6], and the development of cryo-compressed H2 storage technology as a high-density alternative to LH2 storage with reduced sensitivity to heat transfer [7], led to the (possibly temporary) demise of LH2 automobiles.

Hydrogen can’t be distributed with existing natural gas pipelines or service stations because hydrogen leaks as well as corrodes metal. According to former Secretary of Energy Steven Chu (2020), hydrogen seeps into metal and embrittles it, a material problem that has not been solved for decades and may never be solved. Meanwhile, hydrogen is stored in expensive austenitic stainless-steel containers and pipelines that delay corrosion, which must be carefully maintained and monitored, since embrittlement can result in catastrophic explosions with loss of property and life.

Yes indeed, hydrogen is explosive which makes it difficult to use (Heinberg and Fridley 2016, Friedmann et al. 2019). If hydrogen escapes it can explode or catch fire ten times more easily than gasoline, set off with just a spark of static electricity. For example, due to a faulty valve, a Norwegian hydrogen station explosion was so strong that two nearby people inside their cars went to the hospital after their airbags were triggered. Around the same time, a chemical explosion in a hydrogen facility in Santa Clara, California resulted in a cautionary shutdown of all hydrogen stations in the San Francisco Bay Area (Siddiqui 2020). Natural gas has an additive, mercaptan, that imparts a detectable skunky smell but adding an odorant to allow the detection of hydrogen leaks would harm fuel cells. At this point, there are no sensors to detect leaks for pipelines, storage containers, refueling sites, or other enclosed hydrogen storage areas (DOE 2017).

Hydrogen always leaks (it is the smallest element), so eventually a factory or hydrogen gas station risks being blown up, since it is easy to ignite, 12 times easier than gasoline vapor. The smallest of sparks can turn hydrogen into a bomb (Huang 2019, Reuters 2019, Szymkowski 2019). Remember the Hindenburg!

If hydrogen were made off-site to reduce explosion risks, the pipelines, storage tanks, compressors, and chillers would cost 10 times more than natural gas infrastructure, because expensive metal immune to hydrogen embrittlement and to prevent its escape is required (ECRA 2007). Today the natural gas distribution infrastructure has 300,000 miles of long-distance pipe and 2.1 million miles of distribution pipelines would need to be built for hydrogen. But there are only 620 miles of hydrogen pipelines in the US, mainly along the Gulf Coast for oil refining and ammonia fertilizer production.

So, the alternative is for hydrogen to be stored and delivered in $250,000 canister trucks weighing 88,000 pounds (40,000 kg) delivering a paltry 880 pounds (400 kg) of fuel, enough for 60 cars and just a few trucks. A diesel truck can carry 10,000 gallons of gas, enough to fill 800 cars. A hydrogen delivery truck will cannibalize much of its energy: over a distance of 150 miles, it will burn the equivalent of 20% of the usable energy in the hydrogen it is delivering (Romm 2005).

And now that they hydrogen has finally arrived at a filling station, a great deal of energy is required to keep the hydrogen liquefied tank to -423 °F using energy-demanding cryogenic support systems that need to run around the clock (DOE 2019).

If instead, heavy cylinders which will reduce driving range and increase the energy required, are filled with natural gas at $1 million CNG or $2 million LNG stations and carried onboard to be reformed into hydrogen on the truck, then the truck will operate at only 24.7% efficiency. Here’s the math: 84% energy to obtain natural gas * 67% H2 onboard reforming * 54% fuel cell efficiency * 84% electric motor and drivetrain efficiency * 97% aerodynamics, rolling resistance efficiency = 24.7% (DOE 2011). So, why not just burn natural gas? After all, 99% of hydrogen is made from natural gas, not water.

If you wanted to power 5000 hydrogen fuel cell trucks (FCEV) each going 500 miles a day, you would need 10 $75 million dollar hydrogen stations 50 miles apart. That is enough money to build 2500 gas stations. There are no hydrogen sta[1]tions for nonexistent heavy-duty fuel cell electric vehicles (FCEV). Talk about chicken and egg and the valley of death, who is going to build FCEV trucks for nonexistent $75 million dollar hydrogen stations and vice versa (Zhao et al. 2018).

Trucks don’t use hydrogen tanks because they take up 10% of payload weight (DOE 2011), or fuel cells, because the best only last 2500 hours but need to keep on going at least 14,560 hours in long-haul trucks and 10,400 in distribution trucks (den Boer 2013). So why would you even make hydrogen since the #1 problem for civilization is replacing diesel fuel for the heavy-duty trucks that do the actual work of society? (Friedemann 2016). It’s trucks that haul garbage, build roads and buildings, mine the minerals they’re constructed of and the roads they roll on, plant and harvest food, fight fires and more.

And now for a news story about storing hydrogen in salt caverns to help a natural gas power plant generate electricity:

2022 Advanced Clean Energy Storage Project Receives $500 Million Conditional Commitment from U.S. Department of Energy. Businesswire.com.

This hydrogen storage project will cost over $595 million dollars, $504 million funded by the U.S. Department of energy, and provide enough green energy to power 30,000 homes (Fitzpatrick 2022). What!!!??? For 300 million Americans, you’d need 10,000 more of these, or $6 trillion dollars. And that’s just electricity, what about the fossil energy used in manufacturing, transportation, agriculture, mining, half a million products made out of petroleum, natural gas fertilizer and more?

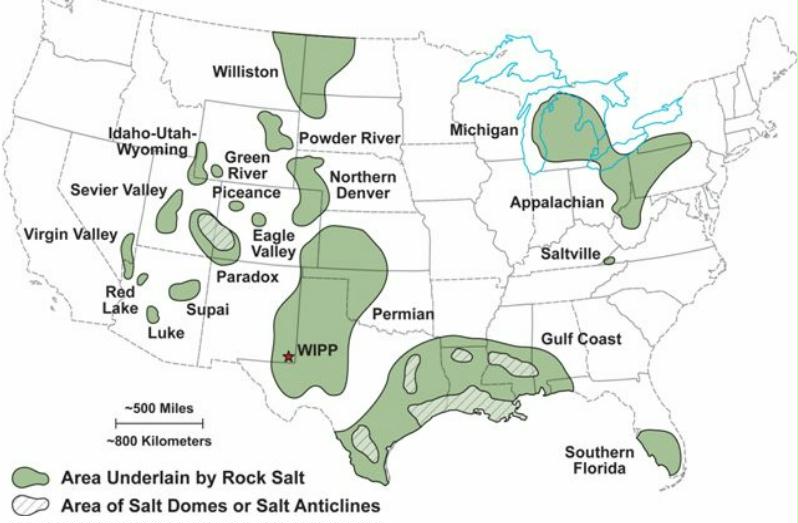

So why was Delta, Utah chosen for this absurdly expensive half a billion dollar “solution”? Because Utah is one of only four states in the U.S. where there are deep underground salt domes. And jobs, jobs, jobs, 425 of them.

Salt domes are the light green, hatched areas:

This is how Compressed Air Energy storage (CAES) works. Excess electricity is used to compress air into very large salt caverns at a depth of 1650 to 4250 feet. In times of electricity demand, it is released to generate more power at natural gas plants. Make that singular, not plural. There is only one small CAES plant in the United States.

Compressed air has never been put in other underground spaces such as rock salt, aquifers, or abandoned rock mines, because the air will escape, so clearly hydrogen, the universe’s smallest element, wouldn’t stick around for long either.

This article would give most people HOPE. But think about it, this doesn’t solve anything if only four states have salt domes. And if this is a good idea, why is there only one CAES compressed air plant helping a natural gas plant produce more power? Air is free, electrolyzing water into hydrogen extremely expensive.

No, this is a one-off Corporate Welfare project, which may actually cost far more, over $595 (Roth 2021), with $500 million of it coming from your tax dollars courtesy of the Department of Energy. Plus free advertising for the for Black & Vetch, Mitsubishi Power, WSP, and NAES corporate wolves in sheep’s “clean and green” clothing. (Sheep actually can be clean and green. When we were in Wales the baby lambs were wearing green raincoats.)

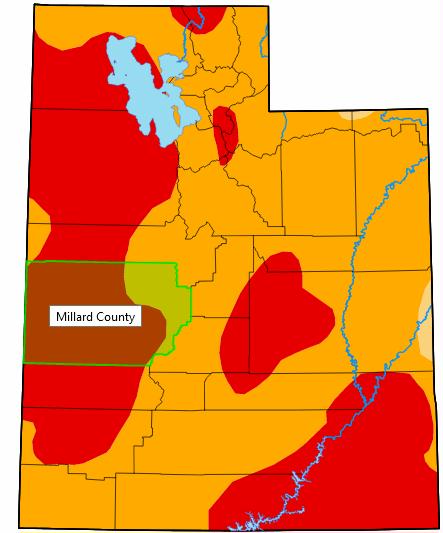

Worse yet, a third of Utah is in an extreme drought in 2022, including Delta in Millard County, so where is the water going to come from? Farms? Towns and cities?

And I just learned I was wrong about the salt dome. So this will be even more expensive, what lies under Delta is salt ROCK, so the cavern will need to be created by hollowing out an area twice as high as the Empire State building with WATER to dissolve the salt, and the briny water pumped out and disposed of somewhere far from where food is grown (Hornyak 2022).

And I just learned I was wrong about the salt dome. It’s a salt ROCK FORMATION that needs to be hollowed out with WATER to dissolve the salt in an area twice as high as the Empire State building. Then the briny water needs to be pumped out and disposed of (Hornyak 2022).

Source: Rippey B, Heim R (2022-4-21) U.S. Drought Monitor. Utah. U.S. Department of Agriculture.

Source: Rippey B, Heim R (2022-4-21) U.S. Drought Monitor. Utah. U.S. Department of Agriculture.

Alice Friedemann www.energyskeptic.com Author of Life After Fossil Fuels: A Reality Check on Alternative Energy; When Trucks Stop Running: Energy and the Future of Transportation”, Barriers to Making Algal Biofuels, & “Crunch! Whole Grain Artisan Chips and Crackers”. Women in ecology Podcasts: WGBH, Jore, Planet: Critical, Crazy Town, Collapse Chronicles, Derrick Jensen, Practical Prepping, Kunstler 253 &278, Peak Prosperity, Index of best energyskeptic posts

***

References Check out all my hydrogen posts here.

Ahluwalia RK et al (2023) Liquid hydrogen storage system for heavy duty trucks: Configuration, performance, cost, and safety. International Journal of Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2022.12.152

Chu S (2020) Steven Chu: Lessons from the past and energy storage for deep renewables adoption. Stanford University.https://gef.stanford.edu/events/steven-chu-lessons-past-and-energy-storage-deep-renewables-adoption

den Boer, E. et al. 2013. Zero emissions trucks. Delft.

DOE (2011) Advanced technologies for high efficiency clean vehicles. Vehicle Technologies Program. U.S. Department of Energy

DOE (2017) Hydrogen delivery technical team roadmap. U.S. Department of Energy and Partner USDRIVE

DOE (2019) Hydrogen production: Natural Gas reforming. Department of energy, EERE

Fitzpatrick T (2022) Plan to fill giant Utah caves with hydrogen gets $504M federal boost. Project under IPP plant near Delta — the first of its kind — would store enough green energy to power 30,000 homes for a year. The Salt Lake Tribune.

Friedemann AJ (2016) When trucks stop running: Energy and the future of transportation, chapter 9. Springer

Friedmann SJ, Fan Z, Tang K (2019) Low-carbon heat solutions for heavy industry: sources, options, and costs today. Center on Global Energy Policy at Columbia University SIPA, New York

Heinberg R, Fridley D (2010) The end of cheap coal. Nature 468:367–369.

Hornyak T (2022) An $11 trillion global hydrogen energy boom is coming. CNBC.

Huang E (2019) A hydrogen fueling station explosion in Norway has left fuel-cell cars nowhere to charge. https://qz.com/1641276/a-hydrogen-fueling-station-explodes-in-norways-baerum/.

Reuters (2019) Explosions and subsidies: Why hydrogen is struggling to catch on in Korea. Accidents and infrastructure are holding it back

Romm JJ (2005) The Hype About Hydrogen: Fact and Fiction in the Race to Save the Climate. Island Press.

Roth S (2021) Newsletter: A hydrogen hub in Utah could power L.A.’s climate future. Now Chevron wants in. latimes.com

Siddiqui F (2020) The plug-in electric car is having its moment. But despite false starts, Toyota is still trying to make the fuel cell happen. The Washington Post